Diamond thin wall drill tool-tip sintering forming die

A diamond and cutter head technology, which is applied in the field of hot-pressing sintering molding molds for diamond thin-walled drill bits, can solve the problems of wasting precious metal materials, difficult disassembly and assembly of molds, and low production efficiency, so as to reduce production costs and improve production efficiency , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

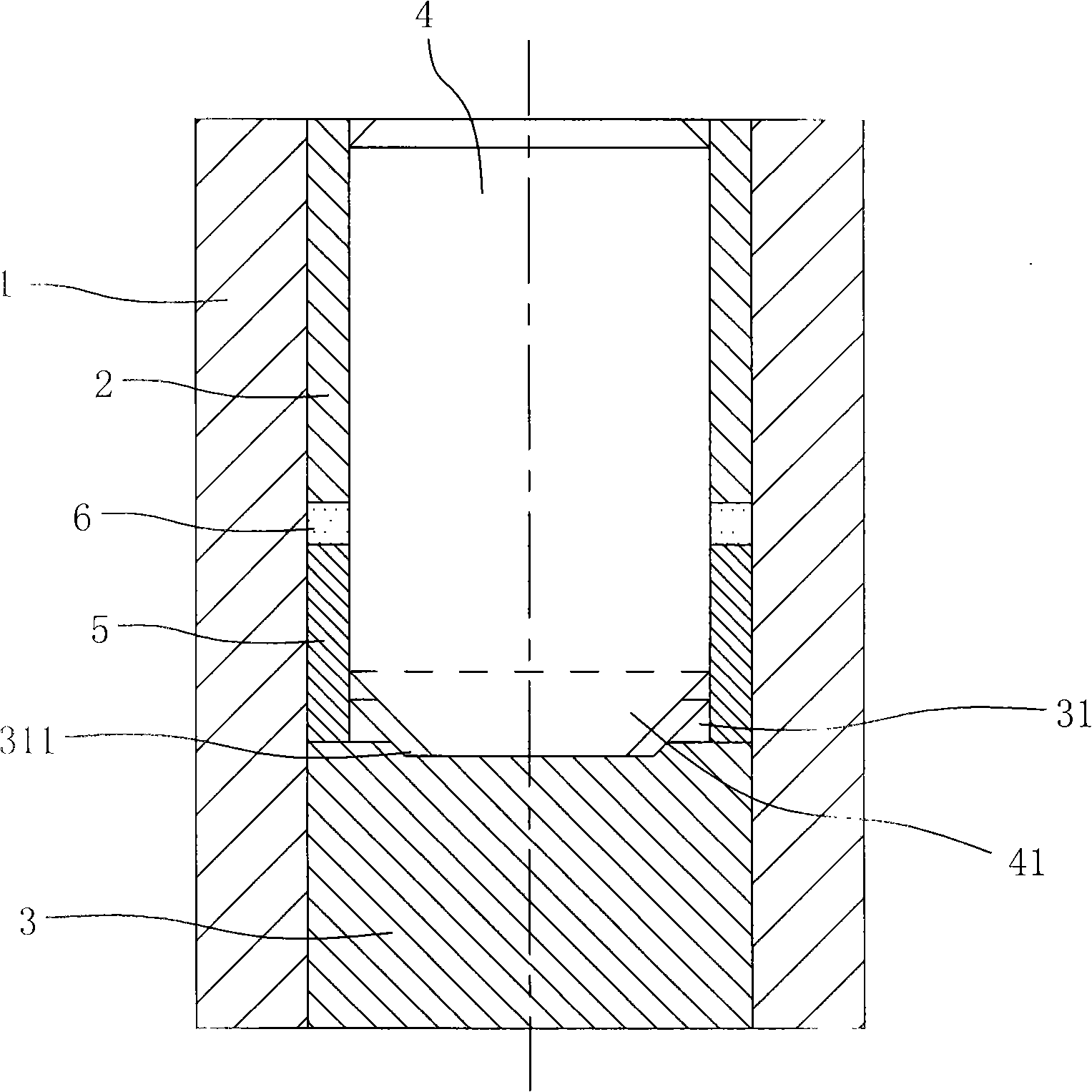

[0019] Such as image 3 , Figure 4 shown. The sintering forming mold of the diamond thin-walled drill head includes a die 1, upper and lower pressing heads 2, 3, a mold core 4 and an insert 5 for forming a water tank of the cutter head.

[0020] Such as image 3 , Figure 4 shown. The die 1 has a central hole that runs through up and down, and the inner diameter of the central hole is equal to the outer diameter of the diamond thin-walled drill bit to be made. from Figure 4 It can be seen from the figure that in order to facilitate easy mold removal and avoid damage to the mold, the die 1 is made into a separate structure, and is formed by closing the left and right symmetrical half dies a and b through the mold clamping mechanism.

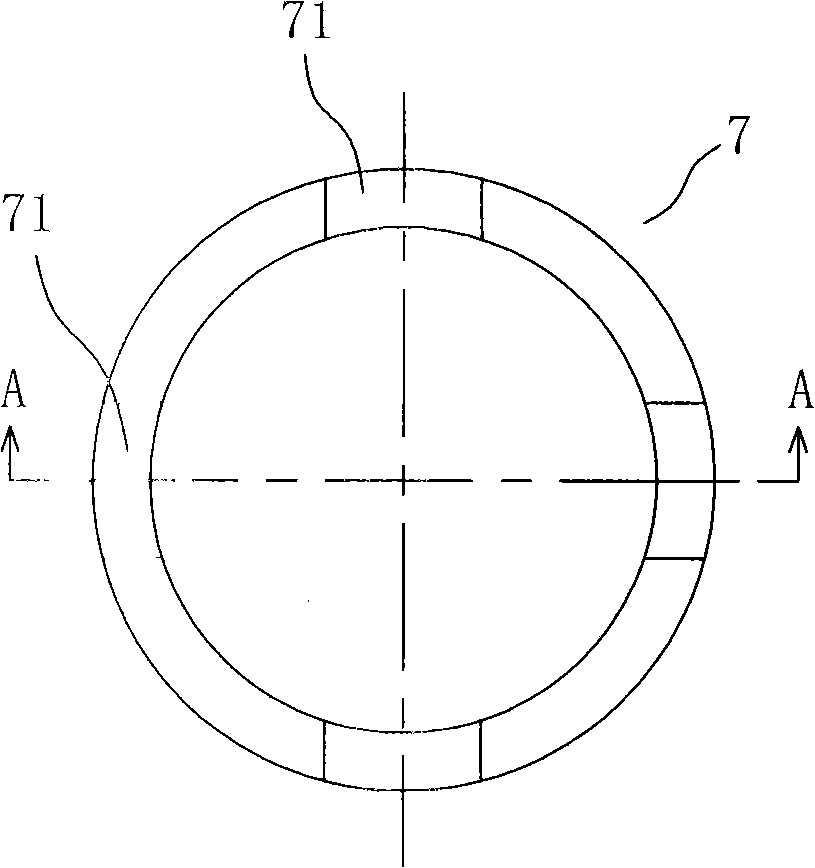

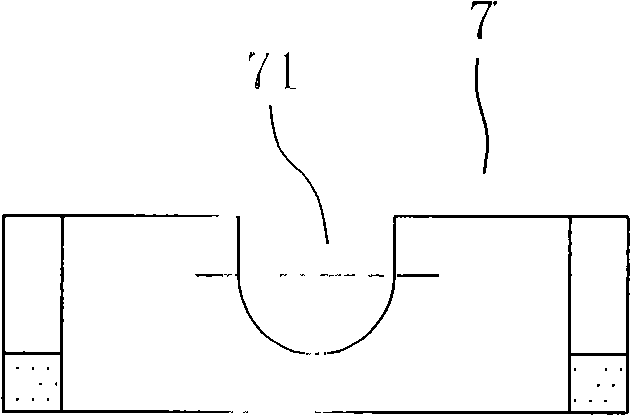

[0021] Such as image 3 , Figure 5 , Image 6 shown. The lower pressing head 3 fits in the center hole of the die and can move up and down along the center hole; the middle part of the top surface of the lower pressing head 3 is reces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com