Liquid gas injection system

一种液体、液体源的技术,应用在混合机、水/污泥/污水处理、生物水/污水处理等方向,能够解决环境污染、鼓风机消耗大能源等问题,达到提高溶解度、节约成本、提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

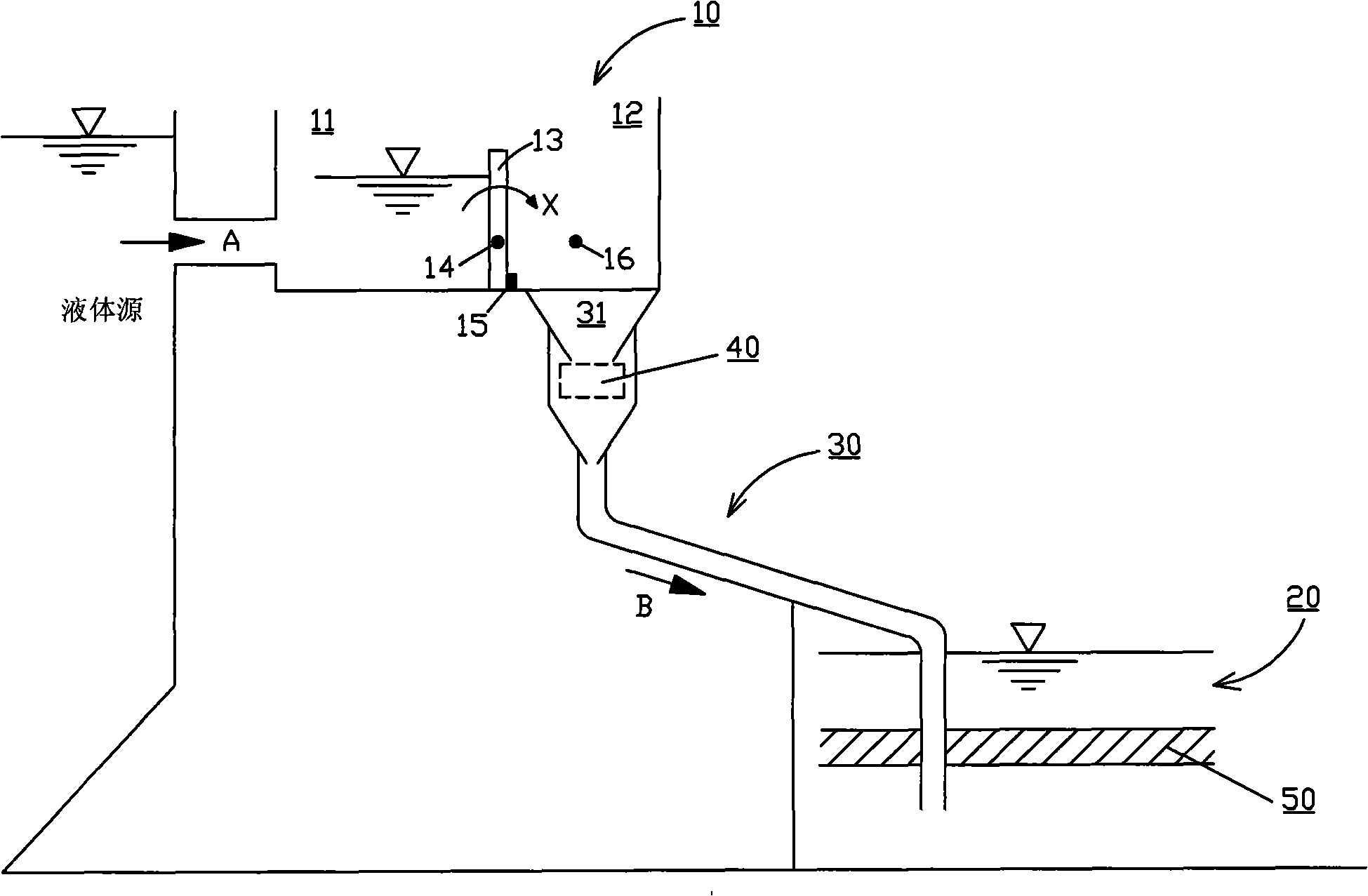

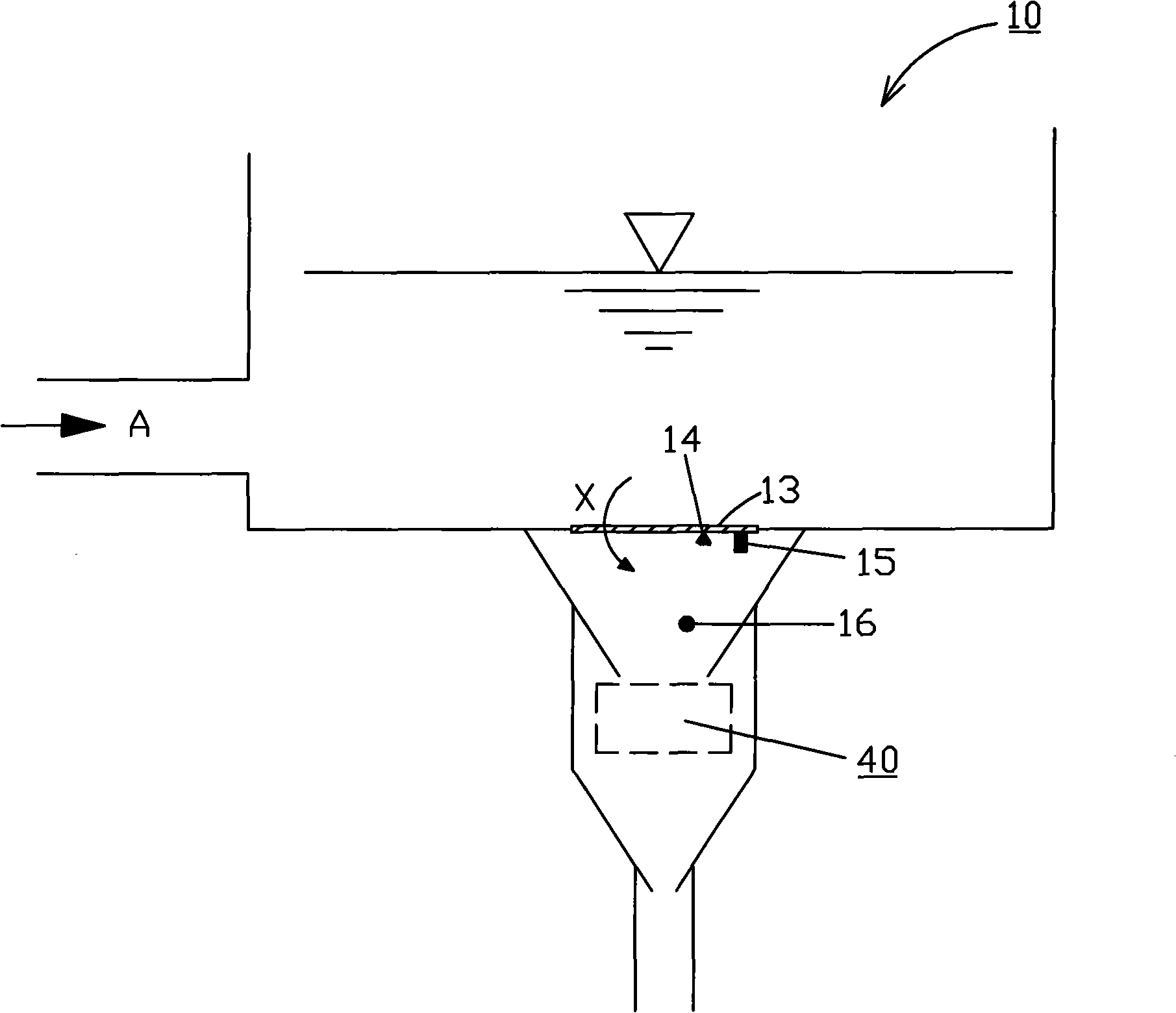

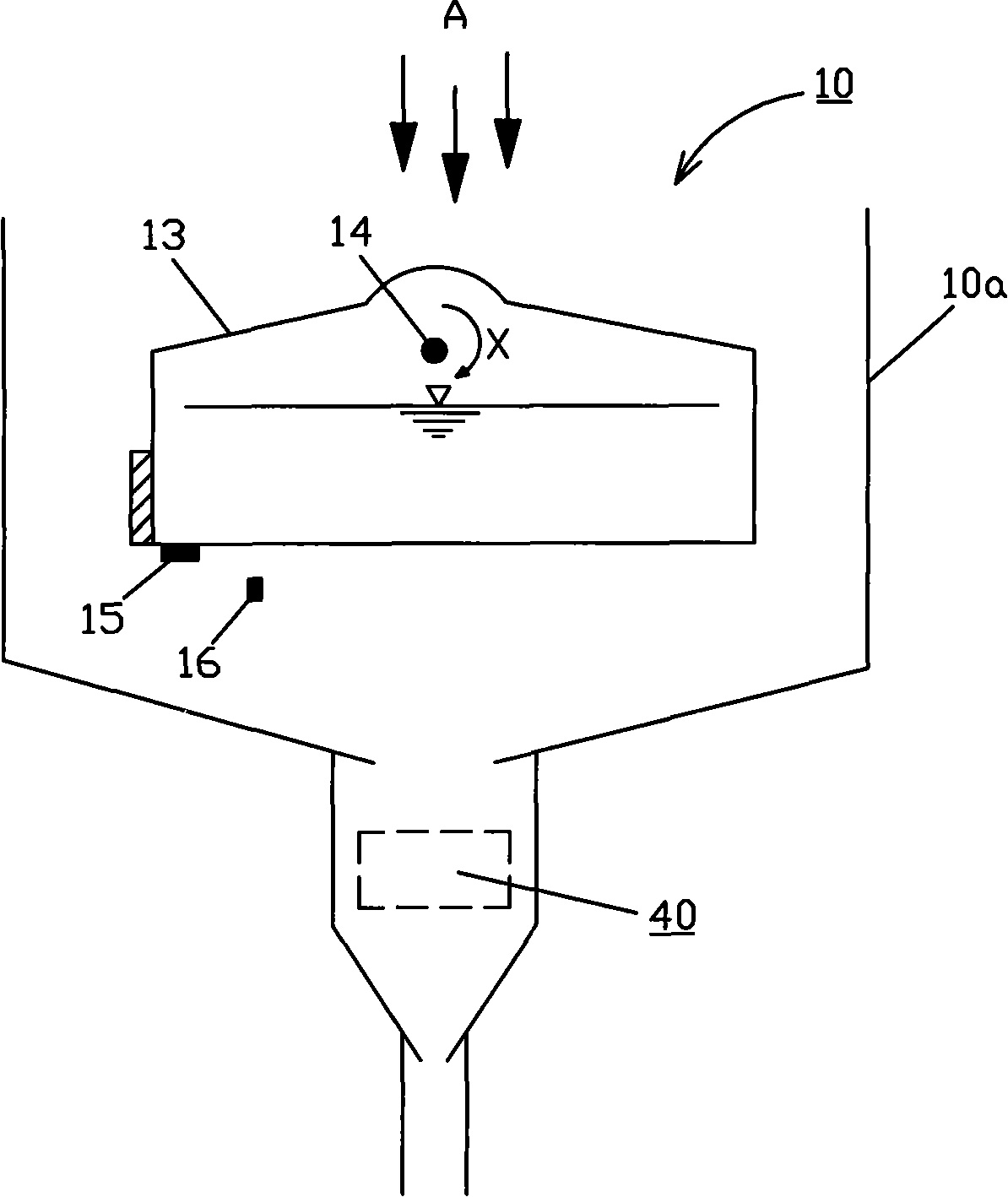

[0017] Such as figure 1 As shown, according to a typical embodiment of the present invention, a liquid gas injection system is provided, which mainly includes: an upstream intermittent liquid supply device 10 for receiving liquid from a liquid source; a downstream liquid storage A device 20 for intermittently and quantitatively receiving liquid from the intermittent liquid supply device 10; and a pipeline 30 connected between the upstream intermittent liquid supply device 10 and the downstream liquid storage device 20, the outlet of the pipeline 30 is located Below the liquid level in the liquid device 20, the liquid in the upstream intermittent liquid supply device 10 is intermittently and quantitatively flowed into the downstream liquid storage device 20 through the pipeline 30 by utilizing the liquid level difference between the upstream and downstream, and at the same time The gas in the pipeline 30 is injected into the liquid in the liquid storage device 20 .

[0018] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com