Semi-fusion type crucible heating device

A heating device and crucible technology, applied in the field of heating device and semi-melting crucible heating device, can solve the problems of unfavorable industrial production application, complex equipment structure and high cost, and achieve the advantages of improving performance, improving heating efficiency and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

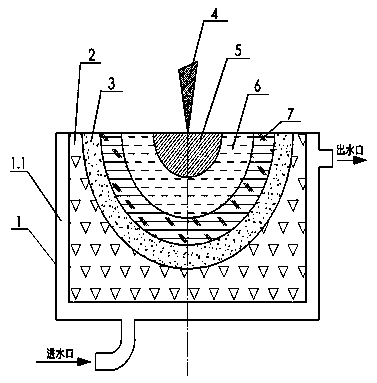

[0022] The plasma heating, evaporation cooling, and physical gas phase method are used for heating, and an appropriate number of crucibles of the same or different materials are first selected to form the crucible layer 3 . When it is necessary to heat metal tantalum with a boiling point of 5425°C, first select a tantalum ingot with a suitable size as the inner layer to be heated, and then wrap a graphite crucible of the corresponding size on the outside of the tantalum ingot, and connect the cooling tank outside the crucible layer 3 1. Install graphite felt between 1.1 as the insulation layer 2, turn on the heating source 4 for heating, after a period of time, the material in the inner crucible is divided into three layers: boiling zone 5, melting zone 6, and solidification zone 7. Collect metal vapors. During the heating process, the cooling tank 1.1 is fed with cooling water, which can effectively cool down the outer crucible and ensure that the crucible layer 3 exists in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com