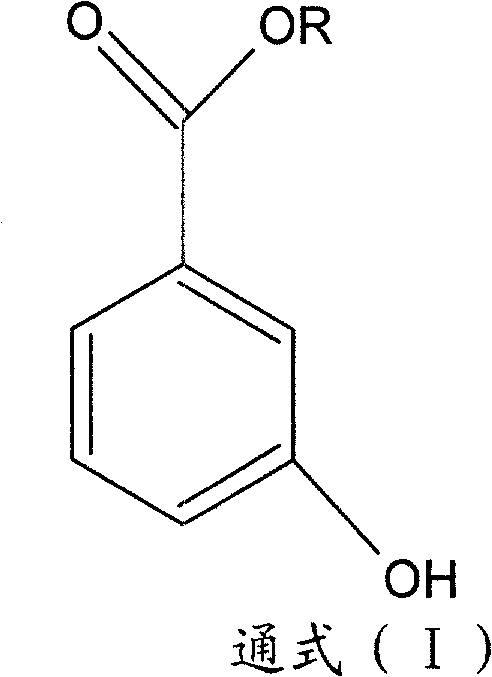

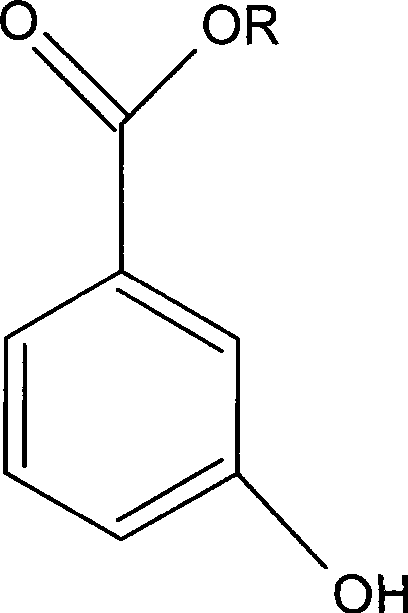

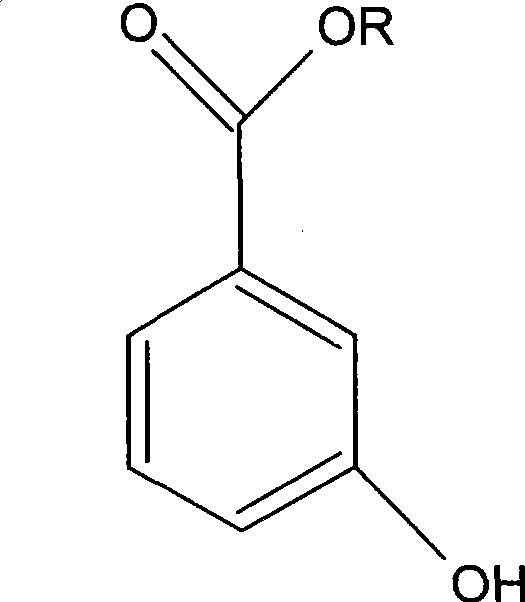

3-hydroxy benzoate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Drop into 2kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) in the reactor, add water 3000ml, stir to make the material in the reactor be slurry, control the internal temperature of the reaction system between 25 ℃ ~ 35 ℃, add dropwise 900 grams (purity ≥ 99.5%) 90%) KOH dissolved in 2500g water lye, until the reaction system PH = 6.4 ~ 6.5, add 60g of activated carbon to the system, stir at room temperature for 30 minutes, decarbonize and filter, spray dry the mother liquor, the inlet temperature is 150°C ~ 190°C, the outlet temperature 70°C-90°C, after spray drying, 2336g of dry solid was obtained, and the molar yield was 91.5%. Product testing results: moisture <1.0%, purity 99.73%.

Embodiment 2

[0033] Add 2 kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) into the reactor, add 1500 ml of water and stir to make the material in the reactor slurry, control the internal temperature at 50°C to 65°C, and add 900g (purity ≥90%) of KOH solution dropwise. Add lye in 1500ml of water until the pH of the reaction system is 6.4~6.5, add 60g of activated carbon to the system, keep the internal temperature at 50℃~65℃, stir and decolorize for 30 minutes, decarbonize and filter, spray dry the mother liquor, and the inlet temperature is 170℃~180℃ , The outlet temperature is 75°C to 85°C. (in the present embodiment: acid: water=1:1.5, because the consumption of water is minimum, the 3-hydroxybenzoate aqueous solution concentration is higher. During spray drying: when the spout of atomizer is moderate in material spray velocity, can not Blockage; if the spray flow rate of the material is adjusted to the highest, the nozzle of the atomizer will occasionally form tiny solid blocks; if the con...

Embodiment 3

[0035] Add 2 kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) in the reactor, add 6000 ml of water and stir to make the material in the reactor slurry, control the internal temperature at 50 ° C to 65 ° C, and drop 860 g (purity ≥ 98%) to obtain Na 2 o 3 Dissolve lye in 4000ml of water until the pH of the salt-forming system is 6.4~6.5, add 70g of activated carbon to the system, keep the internal temperature at 50℃~60℃, stir and decolorize for 30 minutes, decarbonize and filter, spray dry the mother liquor, and the inlet temperature is 158℃~ 190℃, outlet temperature 80℃~95℃. After spray drying, 2110 g of dry solid was obtained, and the molar yield was 91%. Product testing results: moisture <1.0%, purity 99.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com