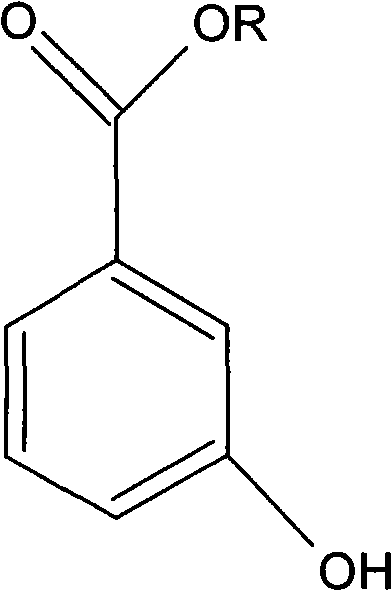

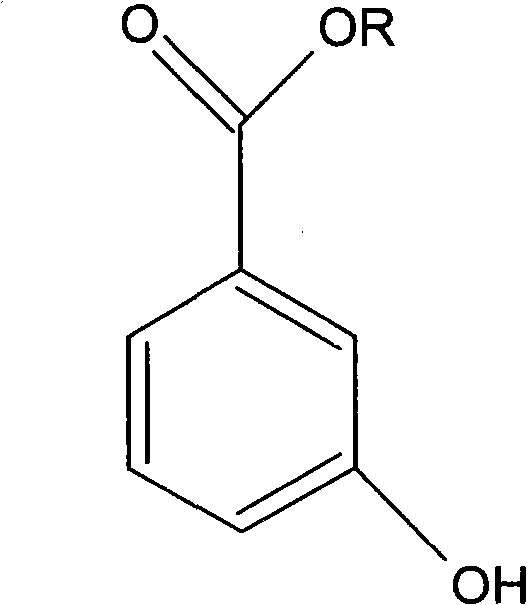

3-hydroxy benzoate preparation method

A technology of hydroxybenzoate and hydroxybenzoic acid, which is applied in the field of preparation of 3-hydroxybenzoic acid monopotassium salt or monosodium salt, can solve the problems of increased production cost, increased organic solvent cost, and harsh operating environment, and achieves The effect of reducing the demand for production equipment, shortening the production cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Drop into 2kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) in the reactor, add water 3000ml, stir to make the material in the reactor be slurry, control the internal temperature of the reaction system between 25 ℃ ~ 35 ℃, add dropwise 900 grams (purity ≥ 99.5%) 90%) KOH dissolved in 2500g water lye, until the reaction system PH = 6.4 ~ 6.5, add 60g of activated carbon to the system, stir at room temperature for 30 minutes, decarbonize and filter, spray dry the mother liquor, the inlet temperature is 150°C ~ 190°C, the outlet temperature 70°C-90°C, after spray drying, 2336g of dry solid was obtained, and the molar yield was 91.5%. Product testing results: moisture <1.0%, purity 99.73%.

Embodiment 2

[0032] Add 2 kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) into the reactor, add 1500 ml of water and stir to make the material in the reactor a slurry, control the internal temperature at 50° C. to 65° C., and add 900 g (purity ≥ 90%) of KOH solution dropwise. Add lye in 1500ml of water until the pH of the reaction system is 6.4~6.5, add 60g of activated carbon to the system, keep the internal temperature at 50℃~65℃, stir and decolorize for 30 minutes, decarbonize and filter, spray dry the mother liquor, and the inlet temperature is 170℃~180℃ , The outlet temperature is 75°C to 85°C. (in the present embodiment: acid: water=1: 1.5, because the consumption of water is minimum, the 3-hydroxybenzoic acid salt aqueous solution concentration is higher. During spray drying: when the spout of atomizer is moderate in material spray velocity, can not Blockage; if the spray flow rate of the material is adjusted to the highest, the nozzle of the atomizer will occasionally form tiny solid ...

Embodiment 3

[0034] Add 2 kg of 3-hydroxybenzoic acid (purity ≥ 99.5%) in the reactor, add 6000 ml of water and stir to make the material in the reactor slurry, control the internal temperature at 50 ° C to 65 ° C, and drop 860 g (purity ≥ 98%) to obtain Na 2 o 3 Dissolve lye in 4000ml of water until the pH of the salt-forming system is 6.4~6.5, add 70g of activated carbon to the system, keep the internal temperature at 50℃~60℃, stir and decolorize for 30 minutes, decarbonize and filter, spray dry the mother liquor, and the inlet temperature is 158℃~ 190℃, outlet temperature 80℃~95℃. After spray drying, 2110 g of dry solid was obtained, and the molar yield was 91%. Product testing results: moisture <1.0%, purity 99.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com