Mineral blending material for producing PHC (Pyrolysis Hydrocarbon) tubular pipe free from high pressure steaming process as well as application

A mineral admixture, high-pressure steam curing technology, applied in the field of mineral admixtures, can solve the problems of difficult to meet construction, low early activity, complex process, etc., to achieve good economic and environmental benefits, simple ingredients, raw material sources wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

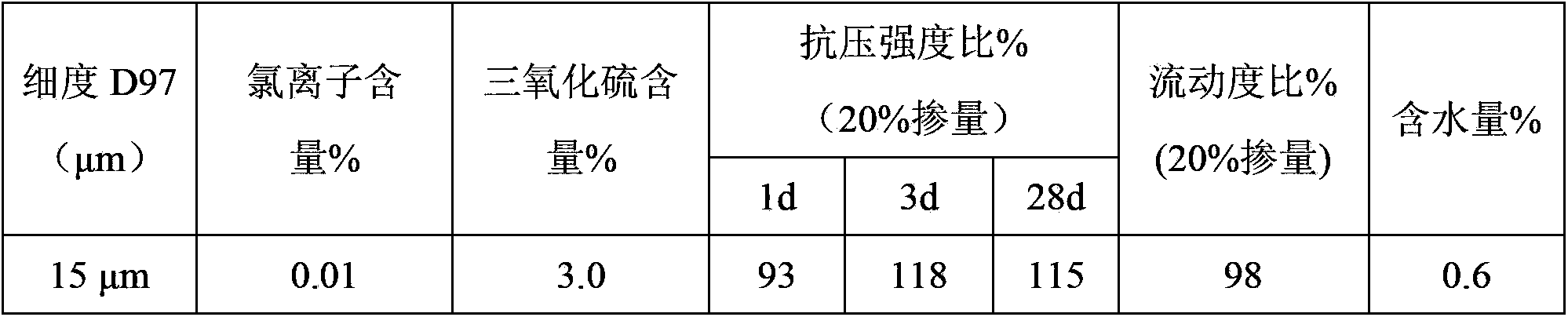

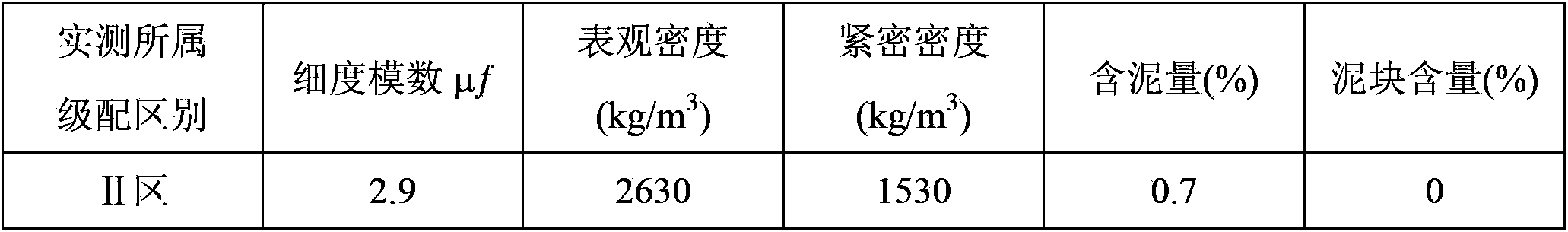

[0031] Evenly mix 80% of superfine blast furnace slag powder and 20% of desulfurized gypsum according to the weight ratio to obtain a high-performance mineral admixture for the production of PHC pipe piles without autoclaving.

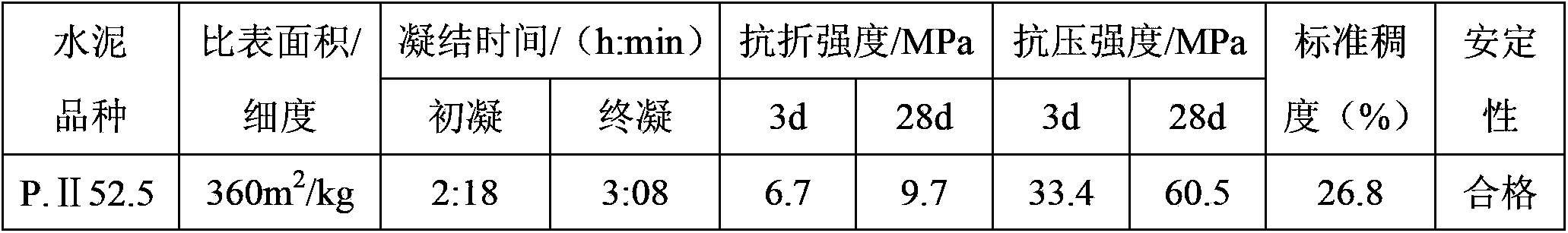

[0032] Mix 20% of the mineral admixture used in the production of PHC pipe piles without high-pressure steam-curing process with 80% of PⅡ52.5 cement to obtain a composite cementitious material. Compared with the standard mortar strength of pure cement, the sand strength is 115% in 1 day, 117% in 3 days, and 111% in 28 days. It has good stability and flow ratio is 103%. ; In addition, other performance indicators of the mineral admixture are as follows: loss on ignition is 2.0%, chloride ion content is 0.014%, and moisture content is 0.5%.

[0033] The steaming system is as follows: static stop for 90 minutes, static stop temperature of 40°C, heating section: 40°C to 90°C, heating time of 90 minutes, constant temperature at 90°C for 4.5 hours, cooling ...

Embodiment 2

[0035] 70% of superfine blast furnace slag powder and 30% of desulfurized gypsum are evenly mixed according to the weight ratio to obtain a high-performance mineral admixture for the production of PHC pipe piles without autoclaving.

[0036] Mix 20% of the mineral admixture used to produce PHC pipe piles without high-pressure steam curing process with 80% of PⅡ52.5 cement to obtain a composite cementitious material, and its basic properties can reach respectively: Compared with the benchmark mortar strength of pure cement, the mortar strength under the steam curing system has a 1-day compressive strength ratio of 116%, a 3-day compressive strength ratio of 118%, and a 28-day compressive strength ratio of 112%. The stability is good , The flow ratio is 104%; In addition, other performance indicators of the mineral admixture are as follows: loss on ignition is 2.0%, chloride ion content is 0.014%, and moisture content is 0.5%.

Embodiment 3

[0038] 60% of superfine blast furnace slag powder and 40% of desulfurized gypsum are evenly mixed according to the weight ratio to obtain a high-performance mineral admixture for the production of PHC pipe piles without autoclaving.

[0039] Mix 20% of the high-performance mineral admixture used to produce PHC pipe piles without autoclaving with 80% of PⅡ52.5 cement to obtain a composite cementitious material, and its basic properties can respectively reach: Compared with the benchmark mortar strength of pure cement under the steam curing system, the mortar strength ratio is 112% at 1 day, 113% at 3 days, and 111% at 28 days. Good performance, the flow ratio is 96%; in addition, other performance indicators of the mineral admixture are as follows: loss on ignition is 2.3%, chloride ion content is 0.015%, and moisture content is 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com