Elastomer structure

An elastomer structure and elastomer technology, applied in the direction of springs, low internal friction springs, springs/shock absorbers, etc., can solve the problems of cylindrical surface deformation on the peripheral side, peripheral expansion, bulging, and reduction of elastic load, etc. Achieve the effect of reducing volume, reducing weight and increasing elastic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

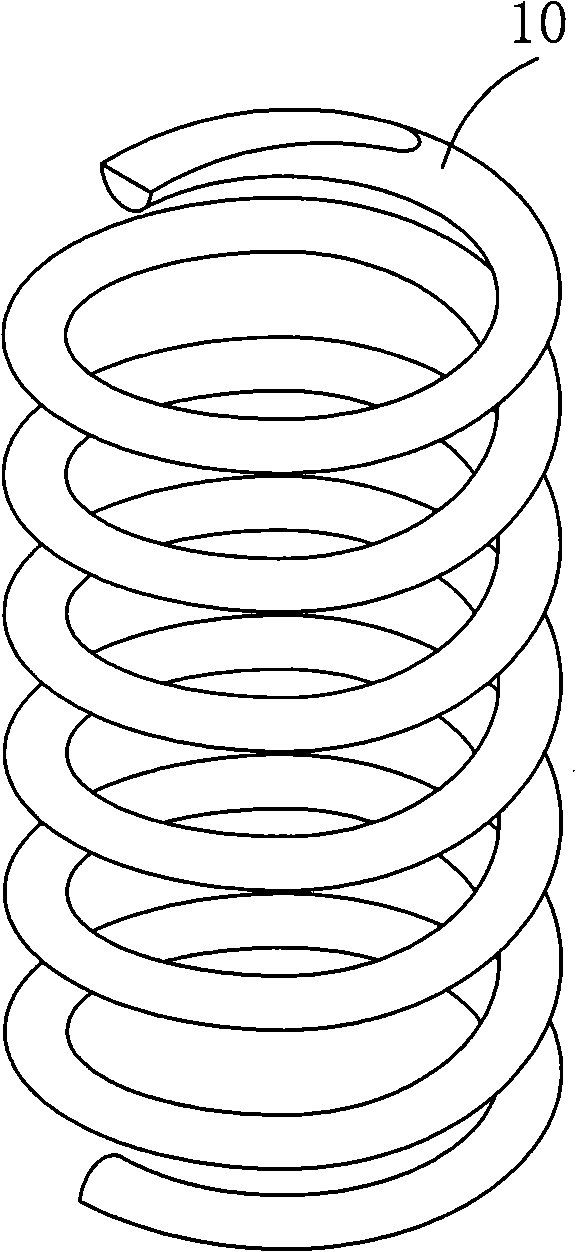

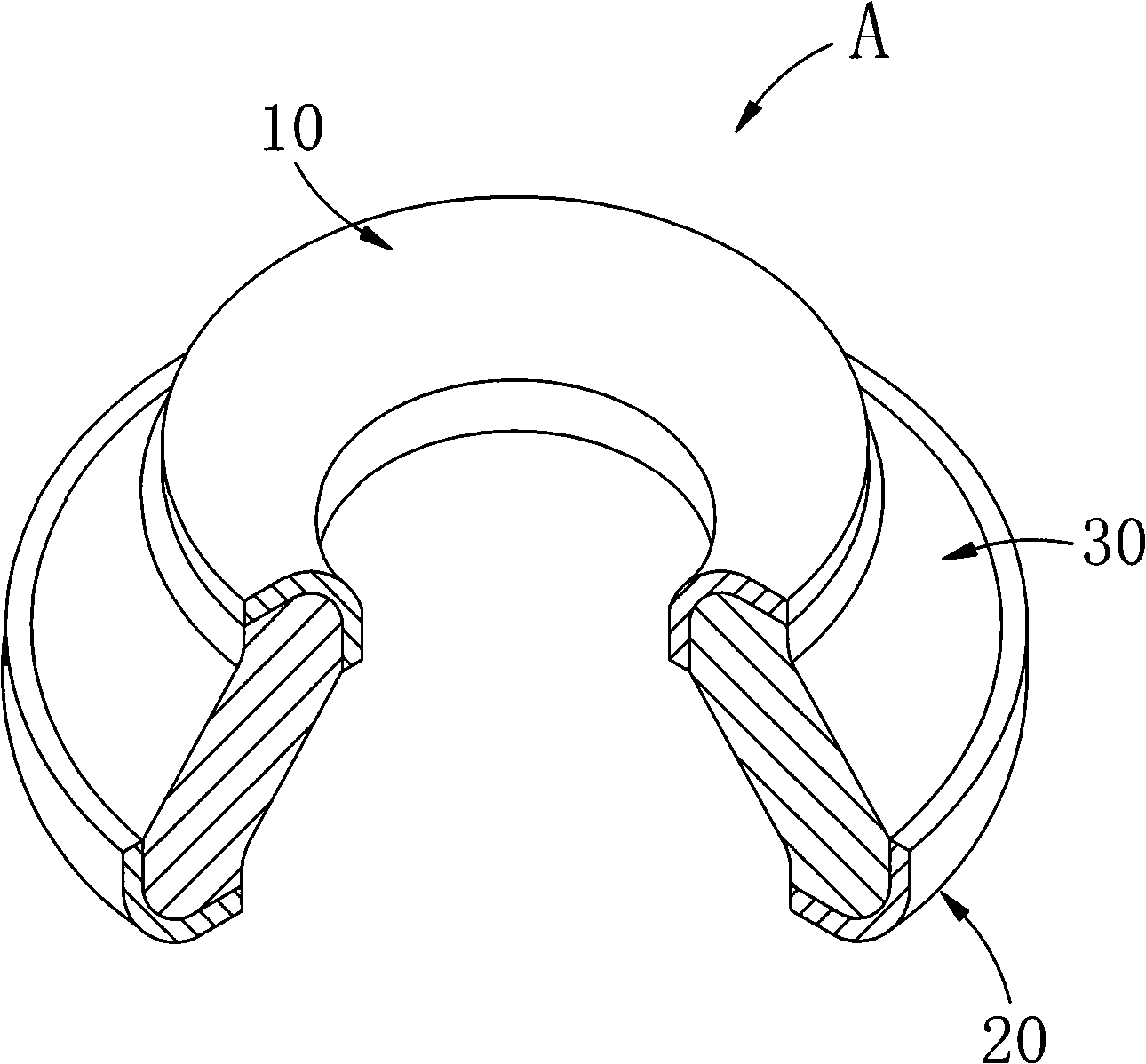

[0091] Please refer to the embodiment of the present invention image 3 , Figure 4 , the improved structure of the present invention is characterized in that:

[0092] The elastic body structure A is combined with the inner blocking body 10, the outer blocking body 20 and the actuating elastic body 30, wherein:

[0093] The inner retaining body 10 is made of an aluminum metal (iron, steel, hard plastic or copper and more rigid materials can also be used), and its outer end is a pressure surface 11, which bears external pressure , and an accommodating space 12 is provided inside the pressure receiving surface 11, and the bottom of the accommodating space 12 is a first retaining edge 13 and a second retaining edge 14;

[0094] The outer retaining body 20 is made of an aluminum metal (iron, steel, hard plastic or copper and more rigid materials can be used in addition), and its outer end is a pressure surface 21, and the pressure surface 21 bears pressure from an external forc...

Embodiment 2

[0101] see again Figure 5 , Image 6 In the second embodiment, with the structure of the first embodiment, the angle 351 of the pressure relief part 35 of the actuating elastic body 30 is made into a radian 352, and the arc 352 allows the actuating elastic body 30 to be accommodated in the inner stopper 10 and the outer stopper When the accommodating spaces 12 and 22 of the body 20 are used, the pressure-receiving surface 11 of the inner baffle body 10 and the pressure-receiving surface 21 of the outer baffle body 20 form a height difference, and the drop allows the inner baffle body 10 and the outer baffle body 20 to move The elastic body 30 creates a space for compression and recovery. The volume and thickness of the pressure relief part 35 can also change the elastic load of the actuating elastic body 30. The rest of the structure, implementation and pressure transmission path of the second embodiment are the same as the first embodiment. No more details here.

Embodiment 3

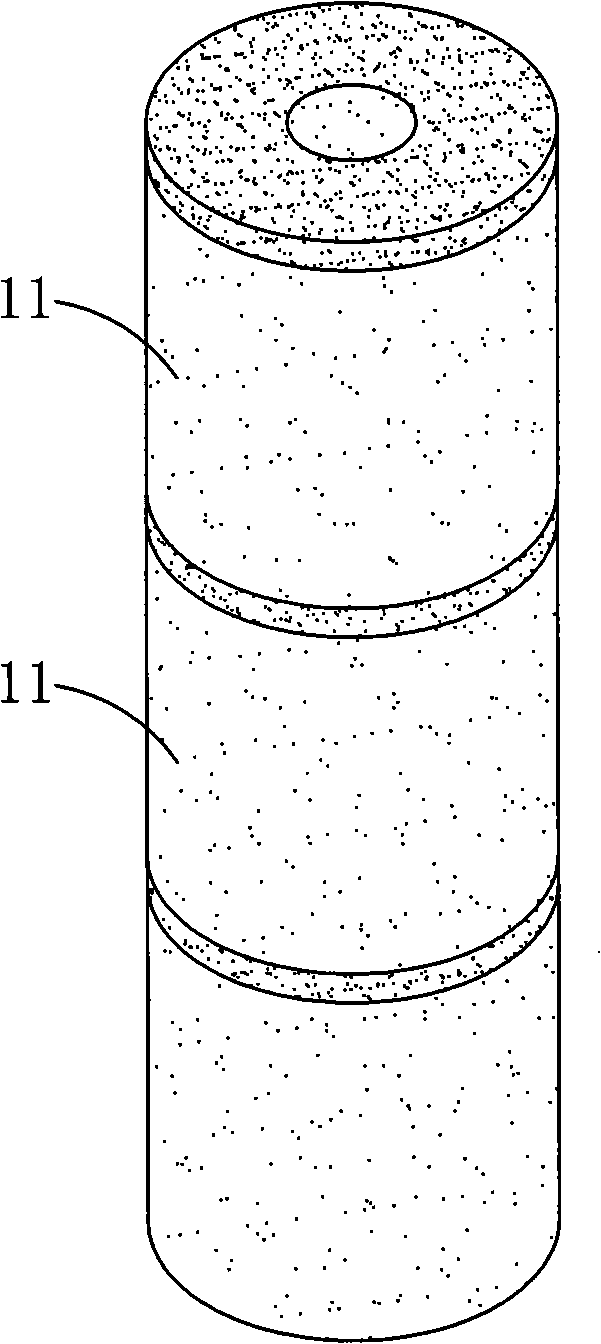

[0103] Also refer to Figure 7 to Figure 9 In the third embodiment, with the structure of the first embodiment, the side ends of the inner baffle 10 and the outer baffle 20 are provided with combination parts, which are composed of several positioning protrusions and positioning concaves, which allow elastic The body structure can be superimposed and used arbitrarily. The combination part of this embodiment can be used in the previous embodiment and the following embodiment. The rest of the structure, implementation mode and pressure transmission path are the same as the first embodiment, and will not be repeated here. repeat.

[0104] In the third embodiment, several positioning protrusions 15 and positioning recesses 16 are formed on the end surface of the inner blocking body 10, and the number of the inner blocking bodies 10 can be stacked arbitrarily to increase. And several positioning protrusions 25 and positioning recesses 26 are made on the end surface of the outer st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com