Dead weight type standard force source device with counterweight independently loading and unloading

A static weight and weight technology, which is applied in the field of independent loading and unloading weight static weight standard force source devices, can solve the problems of difficult to realize weight exchange control, difficult to meet all requirements, difficult to improve work efficiency, etc., to achieve The control device and method are simple and reliable, the structure is simple, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

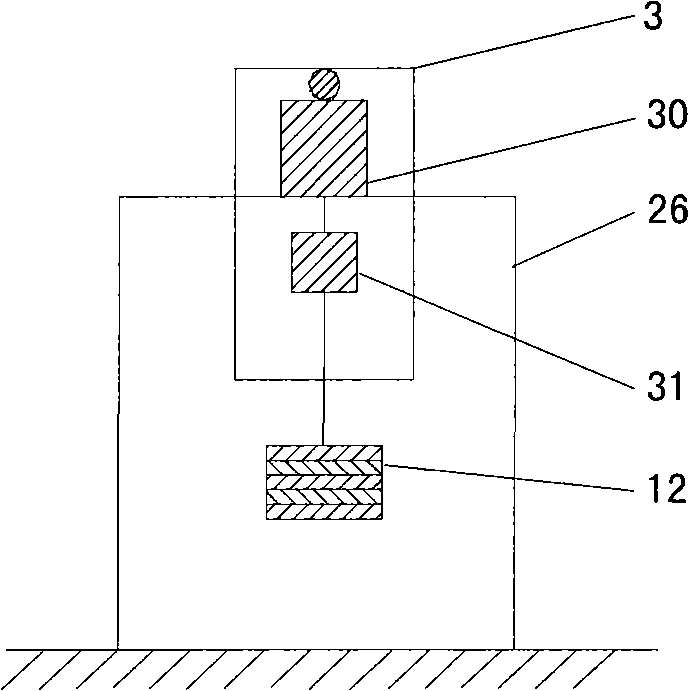

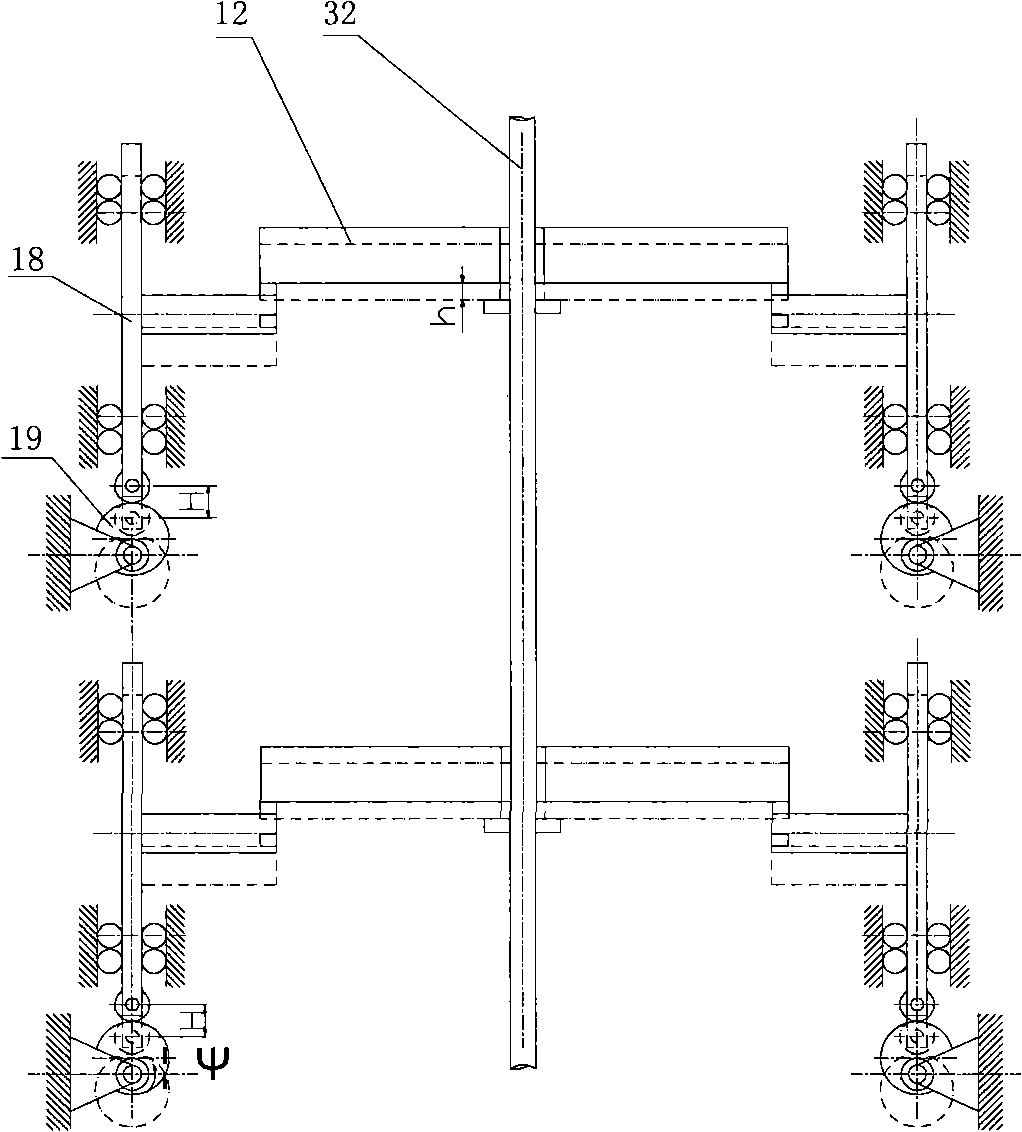

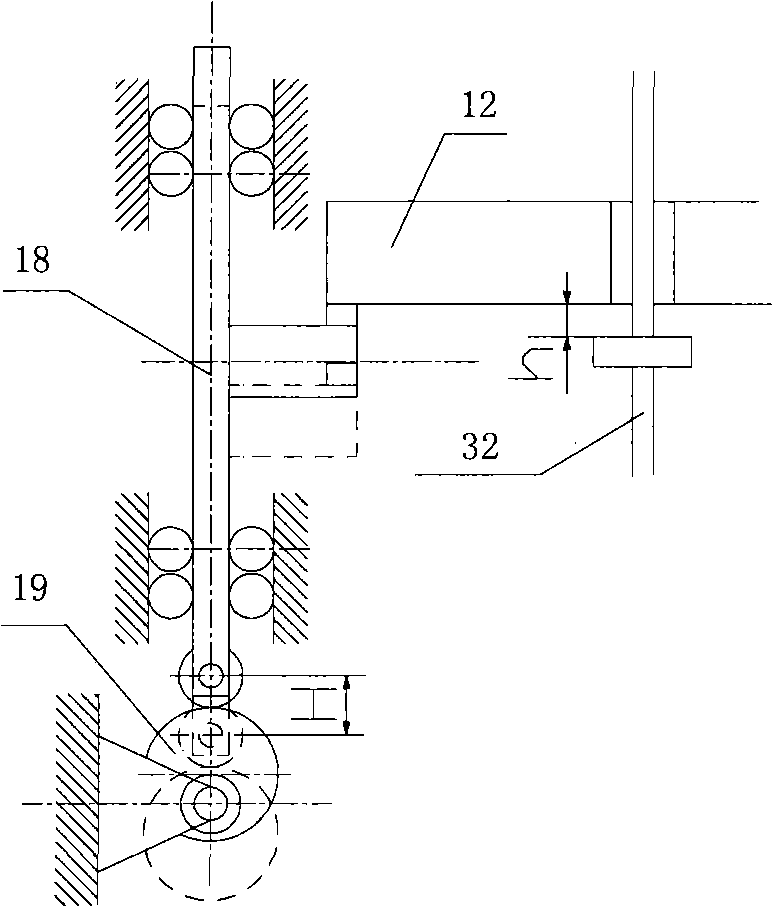

[0038] refer to Figure 9 , what is shown in the figure is a 20kN electric independent weight loading and unloading static weight standard force source device. The electric independent loading and unloading weight static weight standard force source device is a detection device that uses the gravity of the weight 12 as the force source. The gravity of the weight 12 is applied to the tested force through the suspension rod 7 at the center. instrument. Its basic structure consists of a frame 26, a weight electric drive mechanism 10, a suspension 32, a weight 12, an anti-swing device 13 and an electric control system.

[0039] Frame 26 comprises base plate 16, column 9, lower beam 8, leading screw 6, first guide column 4, moving beam 5 and top beam 1 etc., main function is to carry weight, install the dynamometer to be tested. The lower half of frame 26 is the part made up of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com