Reinforced core and optical cable using the reinforced core

A technology for reinforcing cores and optical cables, applied in the direction of fiber mechanical structures, etc., can solve problems such as fiber breakage and damage, interruption of information transmission, small size, etc., and achieve the effects of convenient installation and laying, large transmission information capacity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

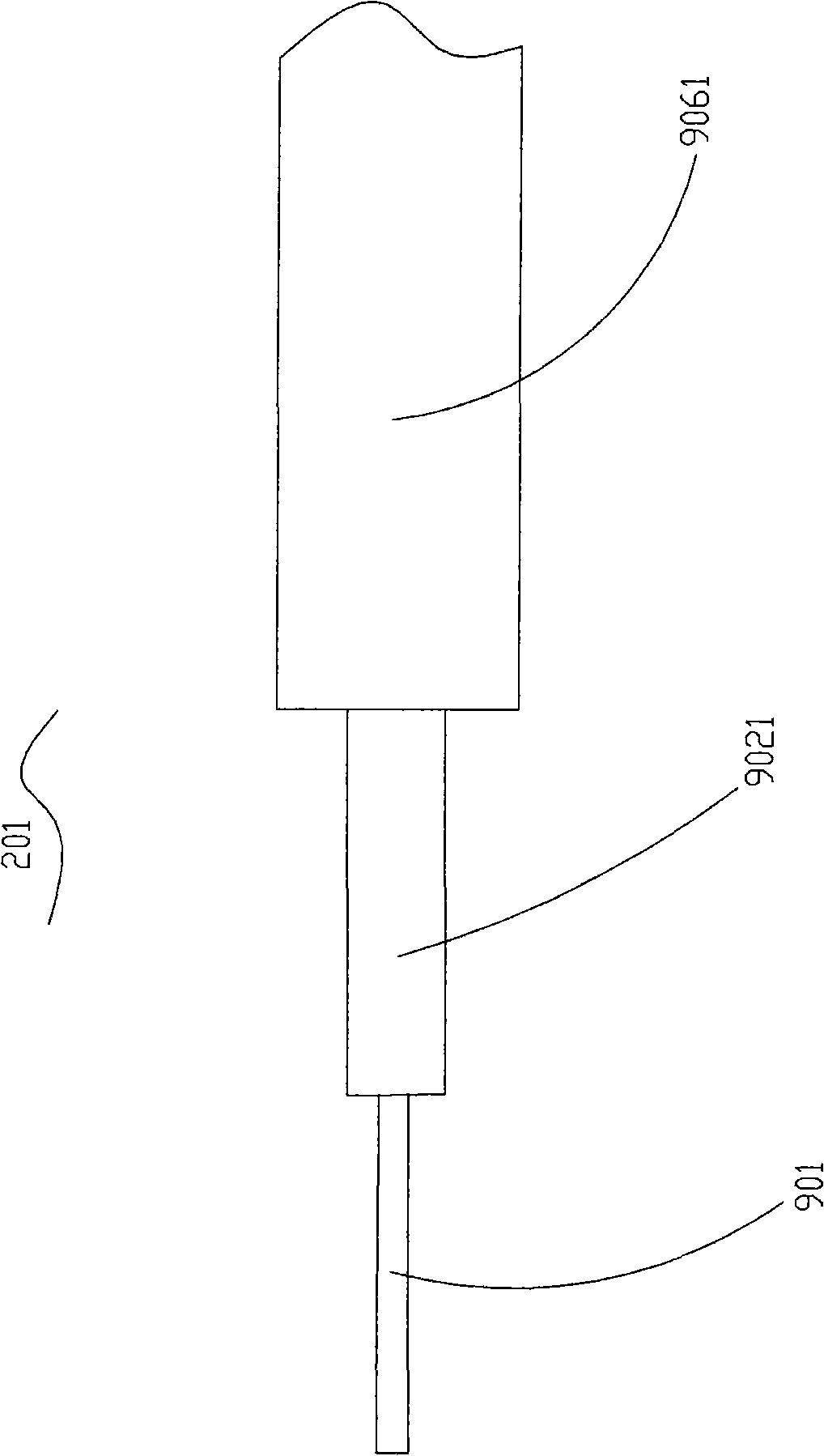

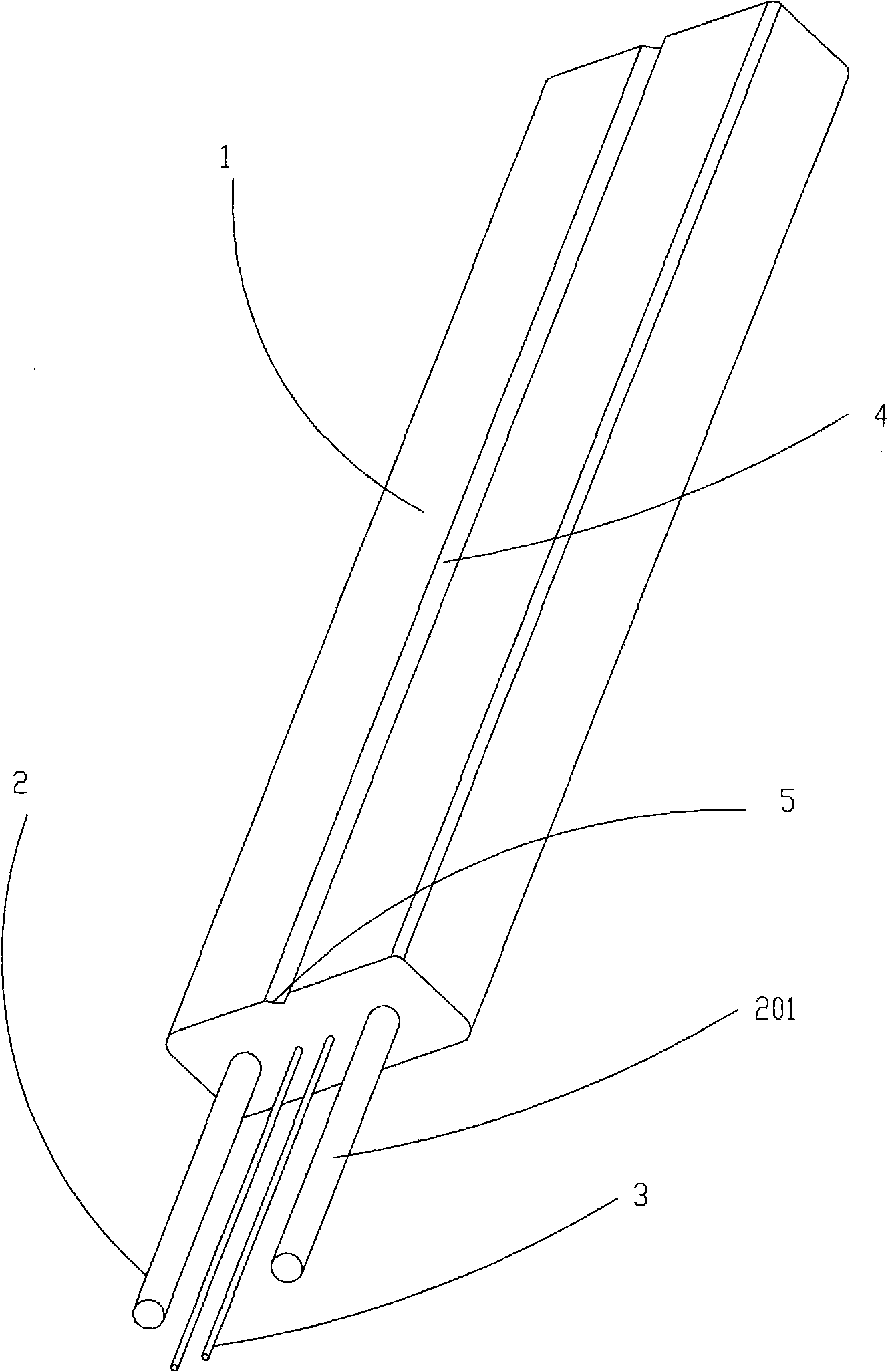

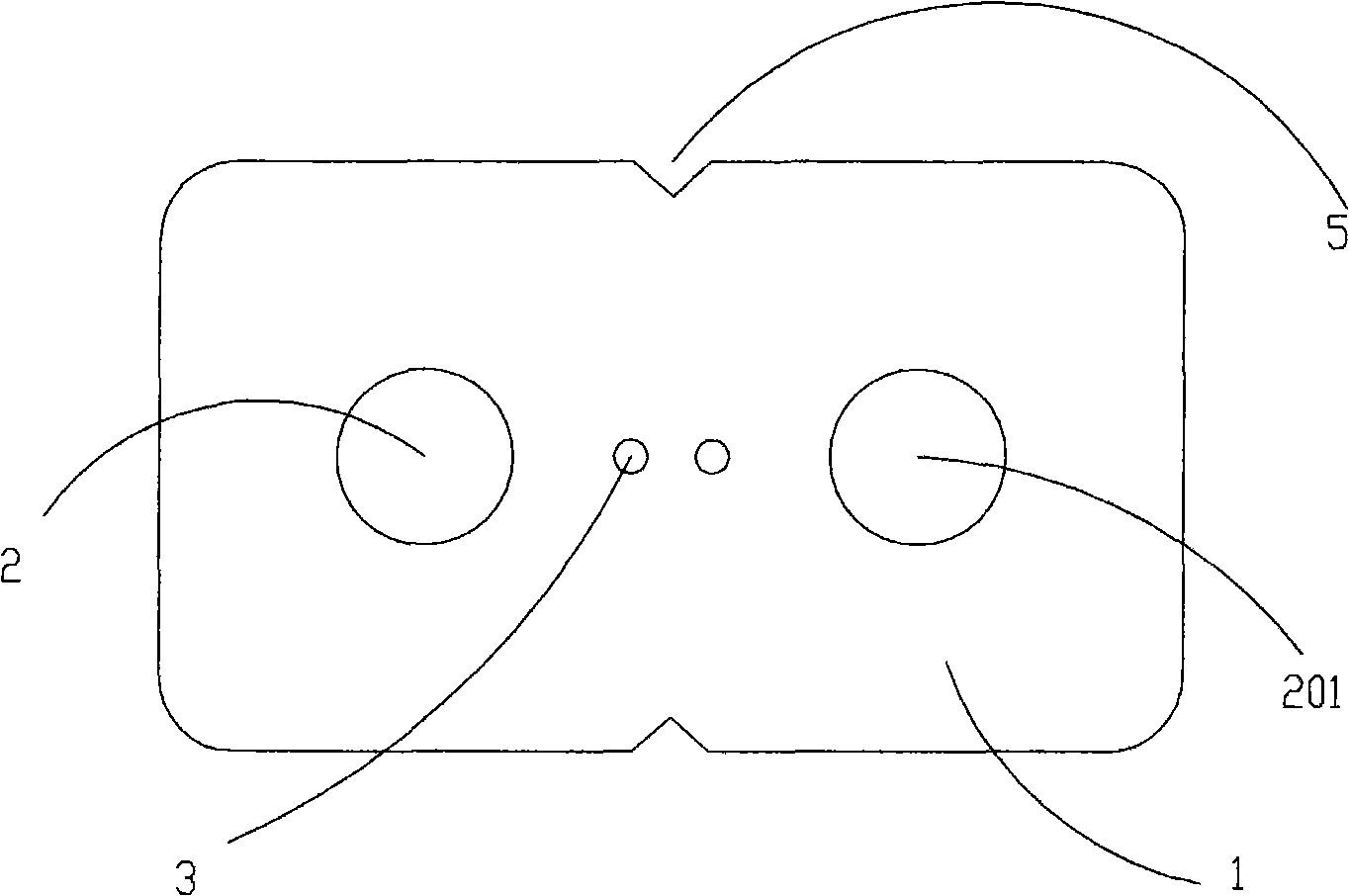

[0015] The strengthening core of the special high-strength anti-bending optical cable of the present invention and the optical cable using the strengthening core are a small-sized (size 2×3MM) communication optical cable suitable for FTTH terminal wiring, which is especially suitable for indoor wiring in buildings, hotels, offices, etc. . As shown in the figure, it includes: 1. Sheath cable body, 2. Strengthening member, 201. Special high-strength bending-resistant optical cable strengthening core, 3. Optical fiber, 4. Groove, 5. Opening.

[0016] The optical cable using the strengthening core is roughly rectangular in shape, which includes a sheathed cable body 1, two reinforced aramid fiber cable strengthening cores 201 integrated in the sheathed cable body 1 symmetrically, and integrated in the sheathed cable body 1. The optical fiber 3 between the two special high-strength bending-resistant aramid fiber cables strengthens the cores 201 . The sheathed cable body 1 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com