Electrowetting display and manufacturing method thereof

A technology for electrowetting displays and pixel electrodes, which is applied to instruments, optical components, optics, etc., can solve the problems of complex manufacturing methods and high manufacturing costs, and achieve the effect of simplifying the manufacturing process and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

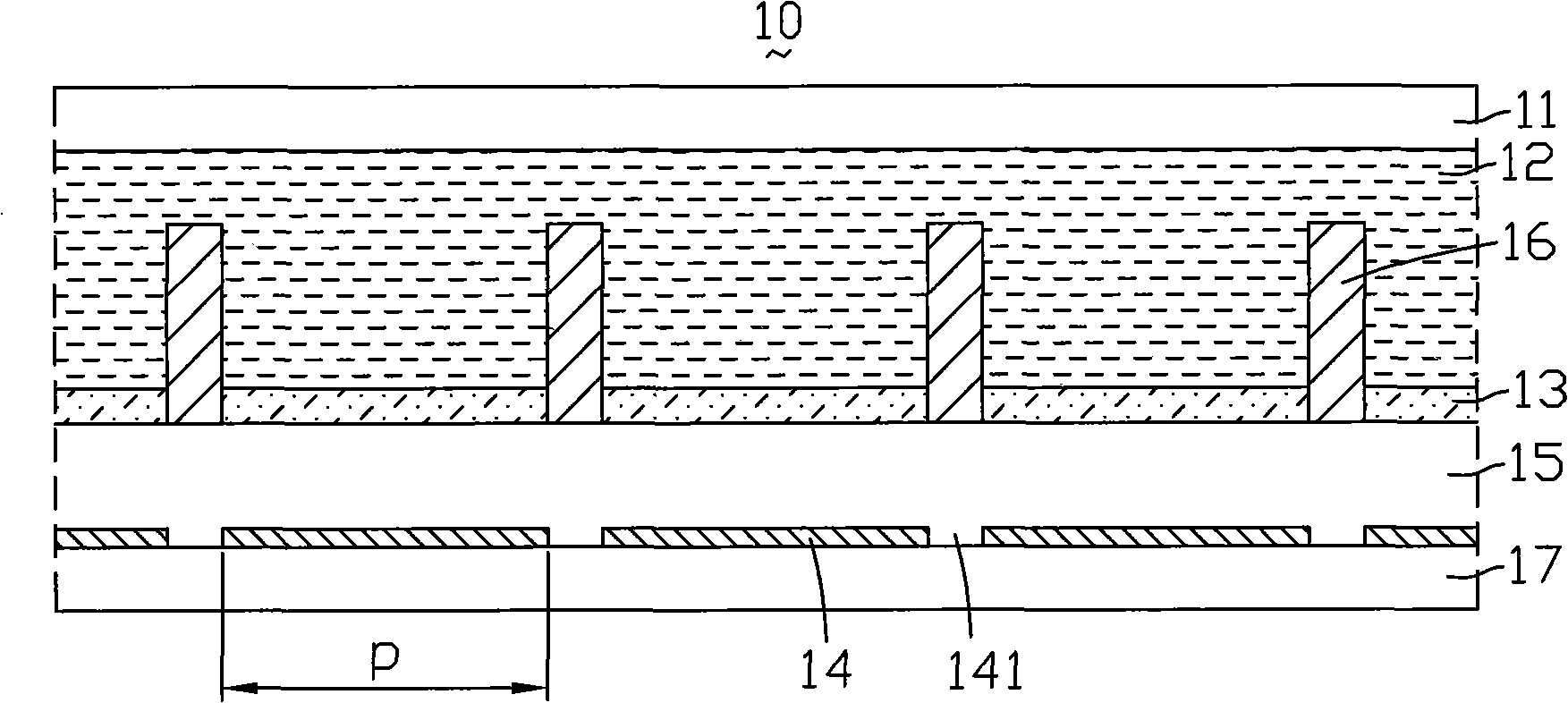

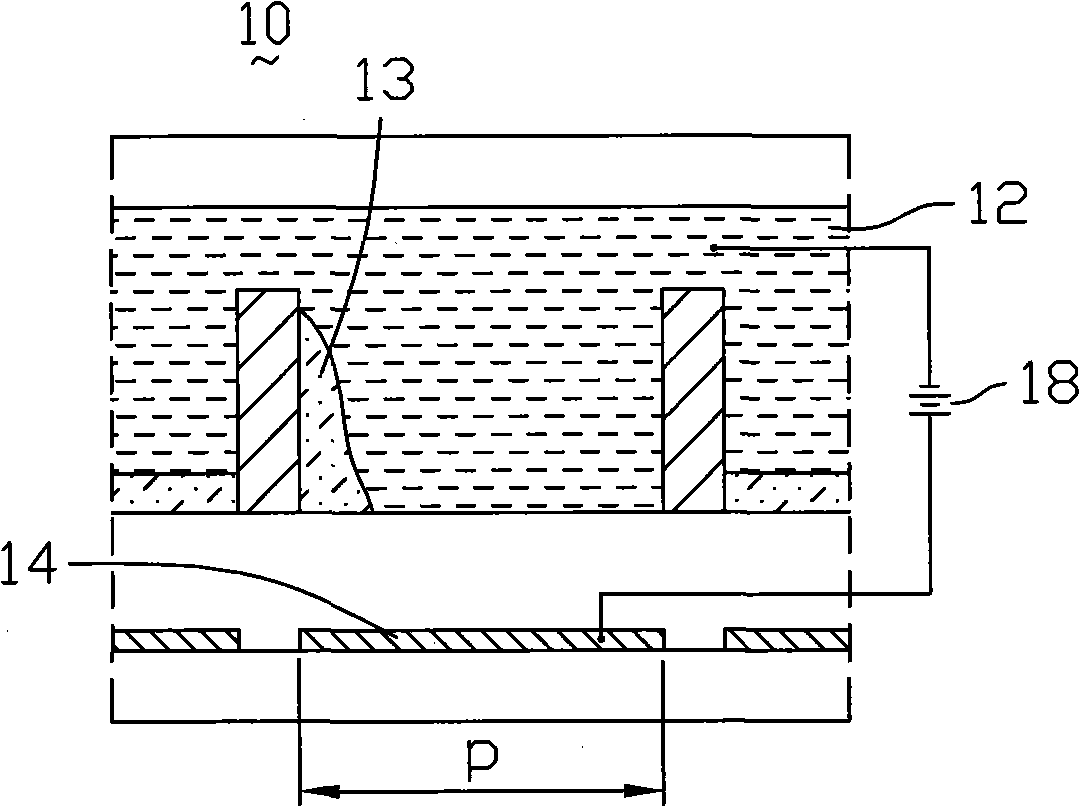

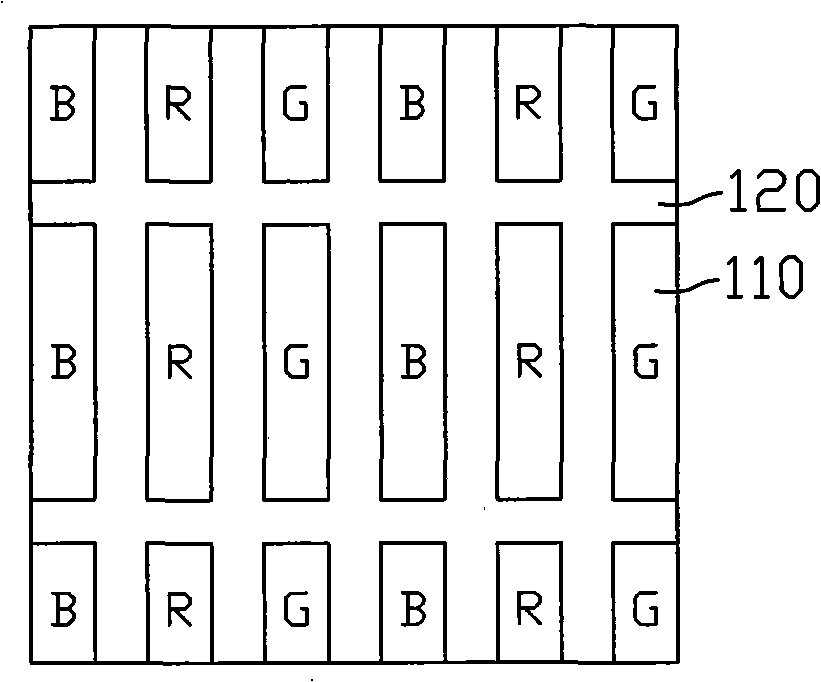

[0029] Please refer to FIG. 4 , which is a schematic cross-sectional view of the first embodiment of the electrowetting display of the present invention when no voltage is applied. The electrowetting display 20 includes a common electrode substrate 21, a matrix circuit substrate 22 disposed opposite to the common electrode substrate 21, and an annular sealant 29 disposed between the two substrates 21, 22, black fluid 23, various Dyed fluids 24 of different colors (including red fluid 24 a , green fluid 24 b and blue fluid 24 c in this embodiment) and a plurality of isolation walls (Pixel Wall) 26 . The ring-shaped sealant 29 is disposed on a peripheral edge of one of the substrates, and is used for laminating and supporting the common electrode substrate 21 and the matrix circuit substrate 22 .

[0030] The common electrode substrate 21 includes a first transparent substrate 210 and a common electrode layer 211 disposed on the surface of the first transparent substrate 210 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com