Electric lamp with an external piston and a fitted lamp and method for production of same

An embedded, electric lamp technology, applied in discharge lamps, circuits, incandescent lamps, etc., can solve the problems of high cost and affect the appearance, and achieve the effect of precise manufacturing, simple manufacturing and load reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

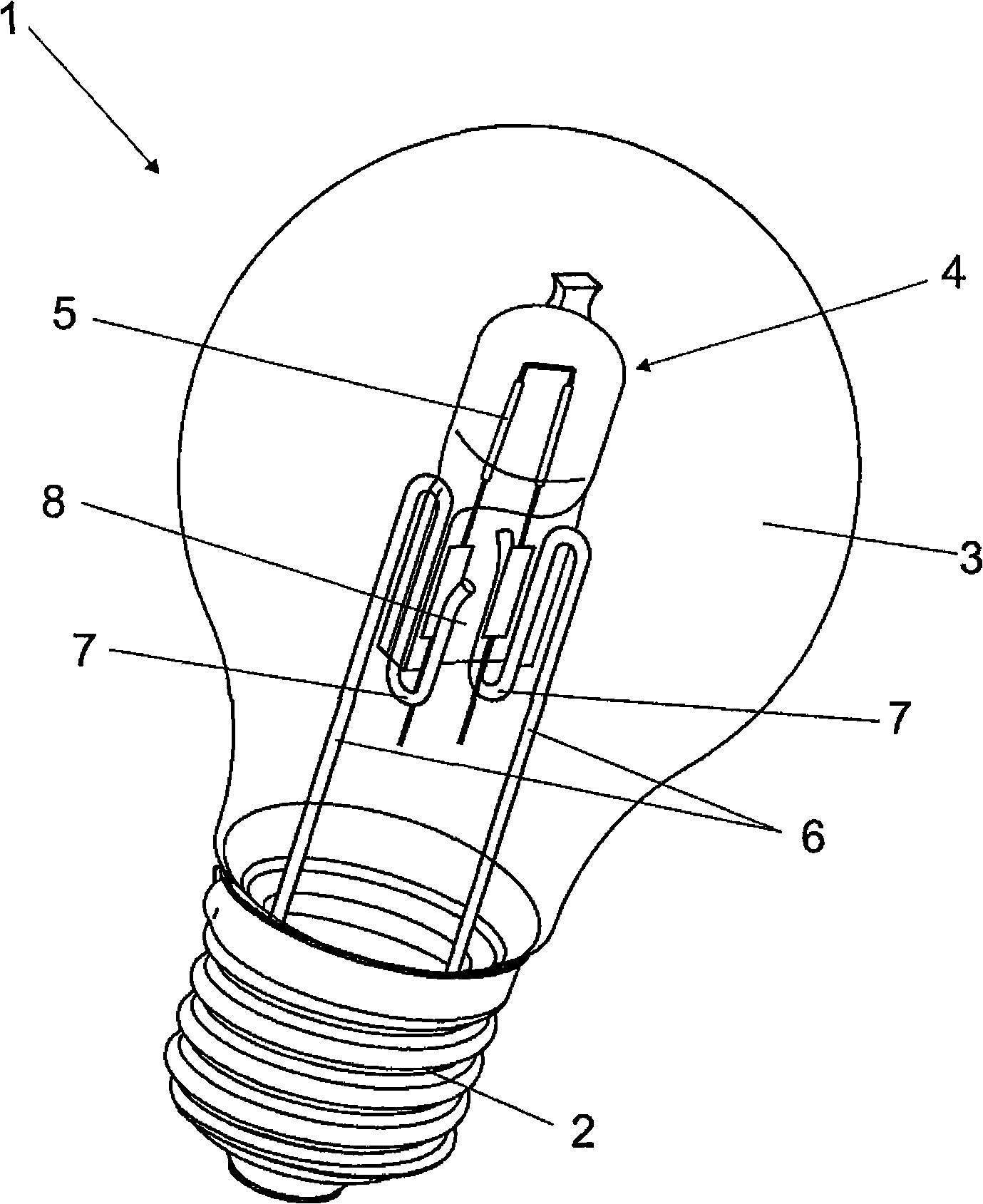

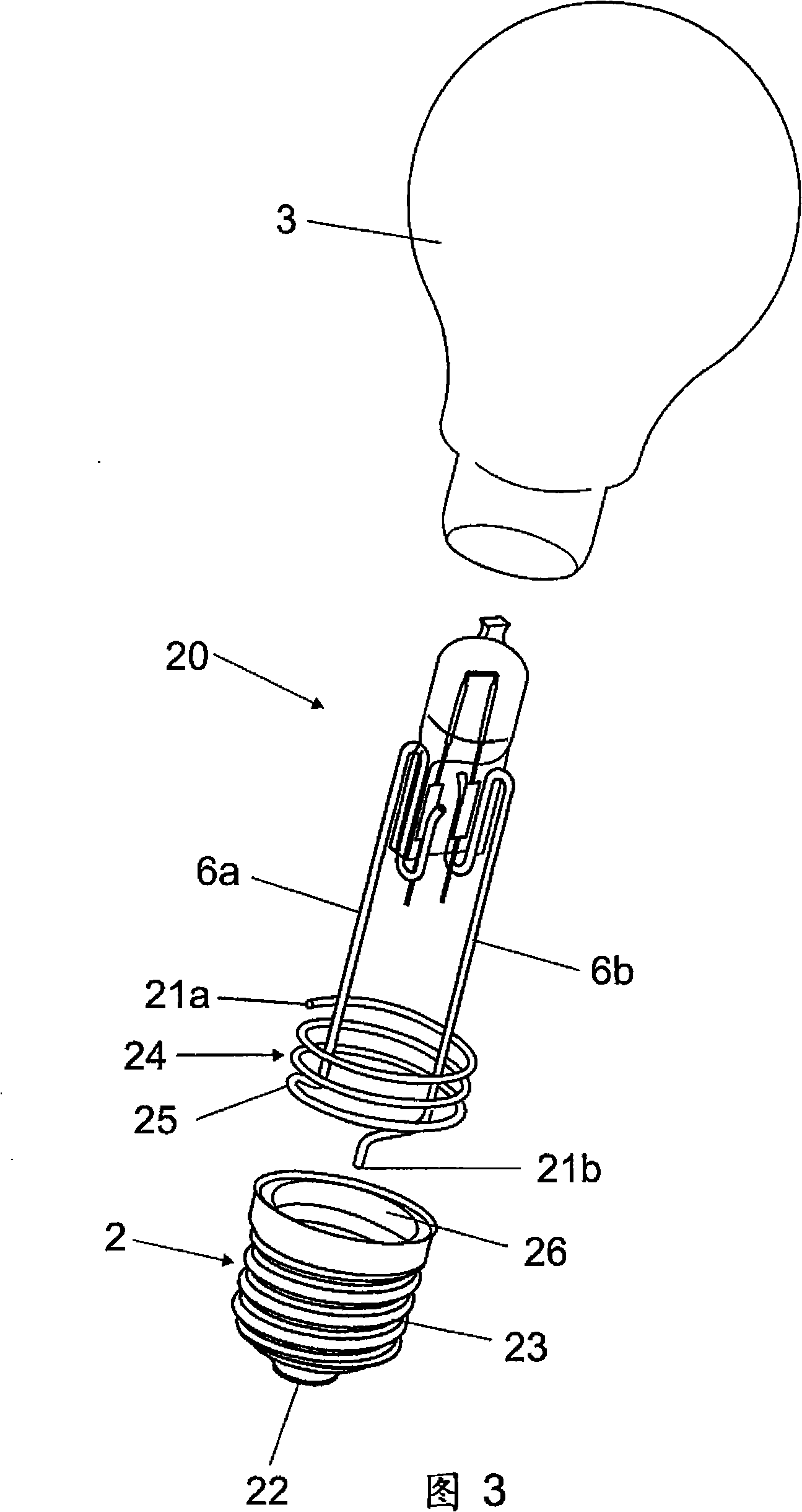

[0029] figure 1 The lamp 1 according to the invention is shown in a perspective view. An outer bulb 3 of model A55 is held in a lamp cap 2 of model E27 which is common on the market. A built-in lamp 4 is arranged in the outer bulb 3 such that an incandescent filament 5 of the built-in lamp 4 is located approximately in the outer bulb 3 at the position where the incandescent filament is likewise arranged in a conventional incandescent lamp. The built-in lamp 4 is implemented as a so-called high-pressure halogen lamp using bulb extrusion technology and is known from the prior art as such a lamp. The built-in lamp 4 is held in two feed lines 6 which are each bent in an S-shape at their built-in lamp-side ends. As a result, a U-shaped bend 7 is formed in each case, in which bend the base 8 of the integral lamp 4 is held.

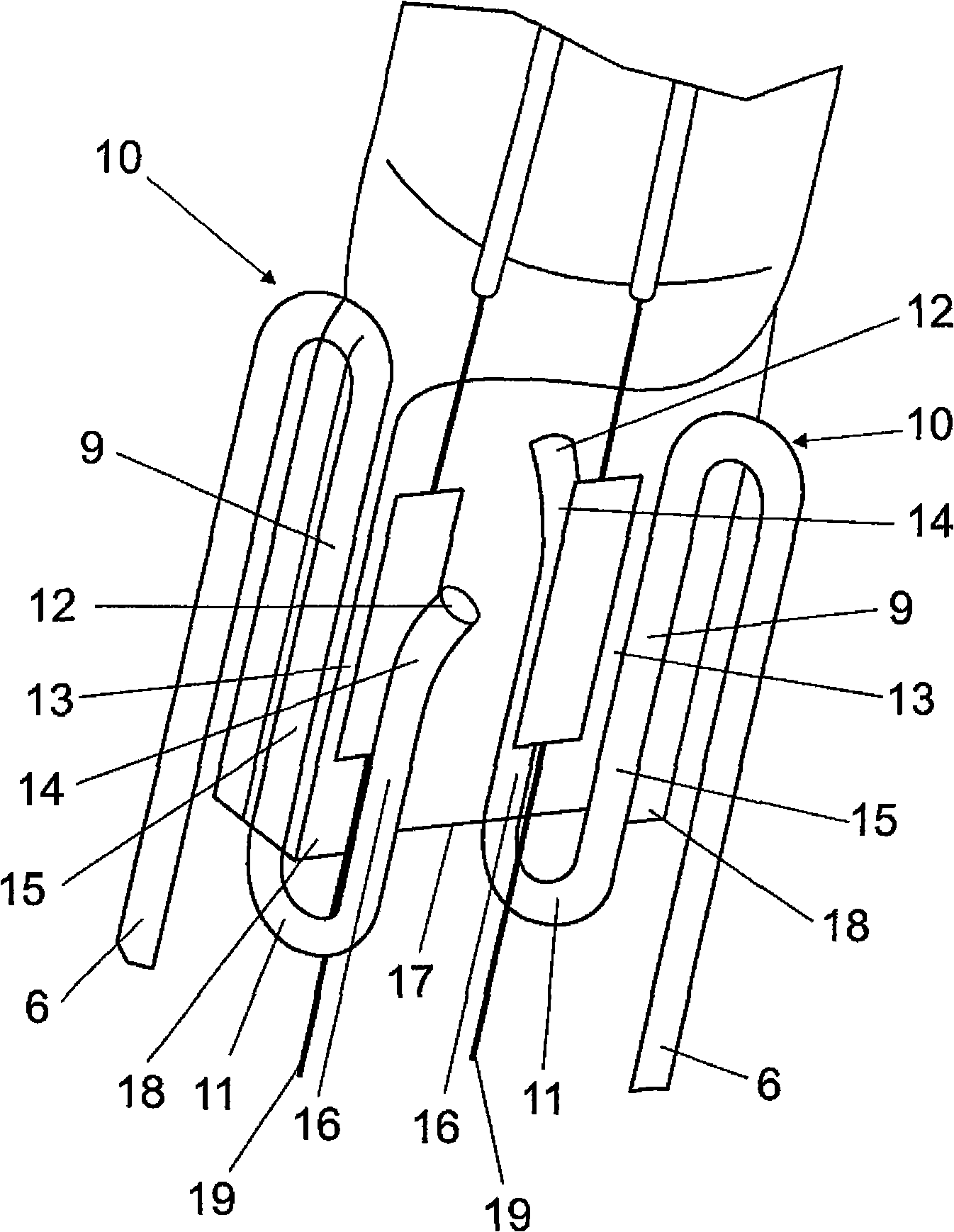

[0030] exist figure 2The details of this construction can be seen particularly clearly in . Starting from the base 2 of the lamp 1 , the feed line 6 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com