Apparatus for manufacturing thin-film laminated member

A technology of laminates and films, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as wrinkles, and achieve the effect of preventing bending, high precision, and preventing sagging and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Referring now to the accompanying drawings, the apparatus for manufacturing a thin film laminate of the present invention will be described in more detail as follows. Although the detailed configuration of the thin film laminate is not specifically described here, the present invention is applicable to the manufacture of photoelectric conversion elements such as solar cells or semiconductor thin films such as organic EL (Electroluminescence Element).

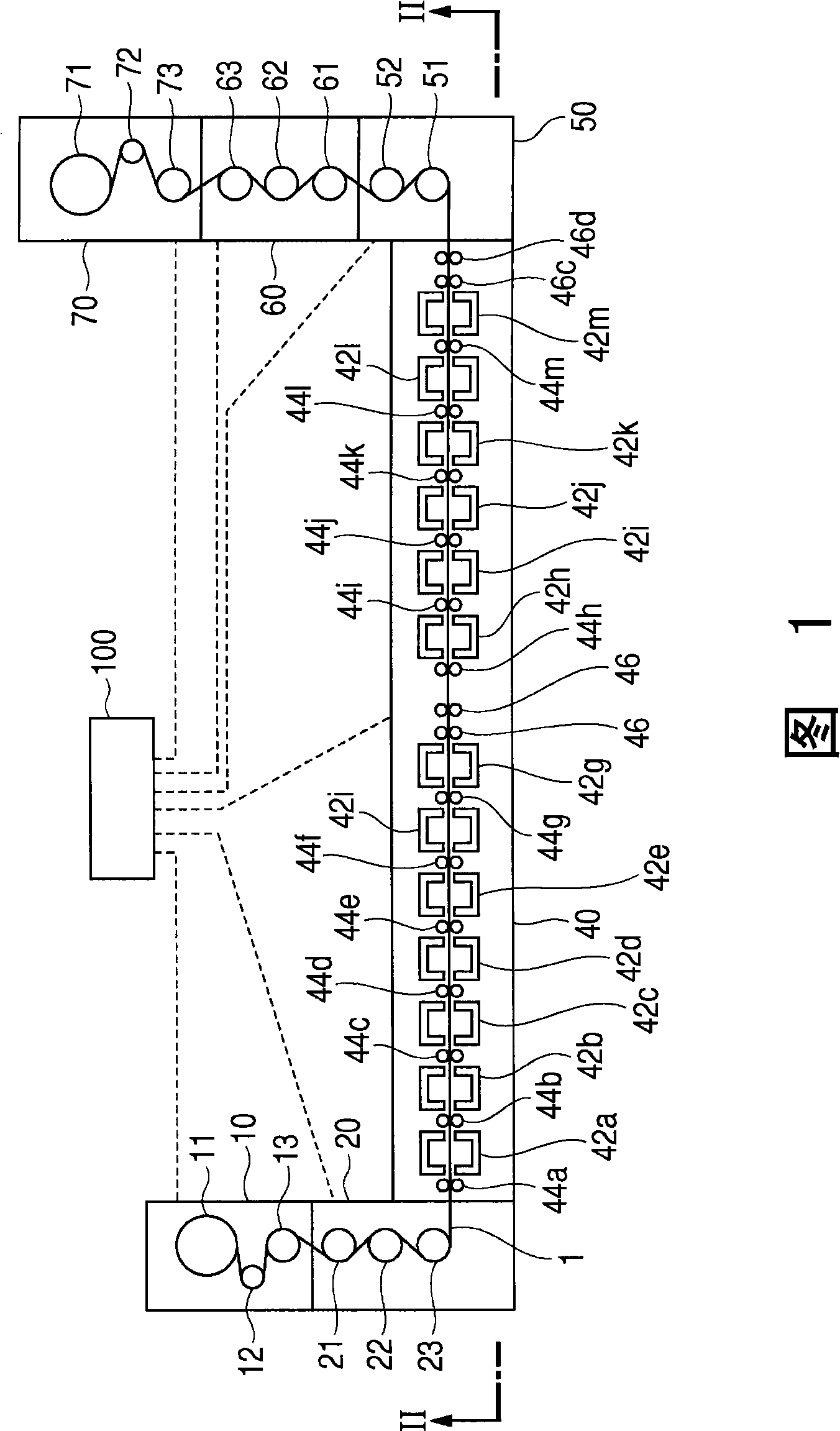

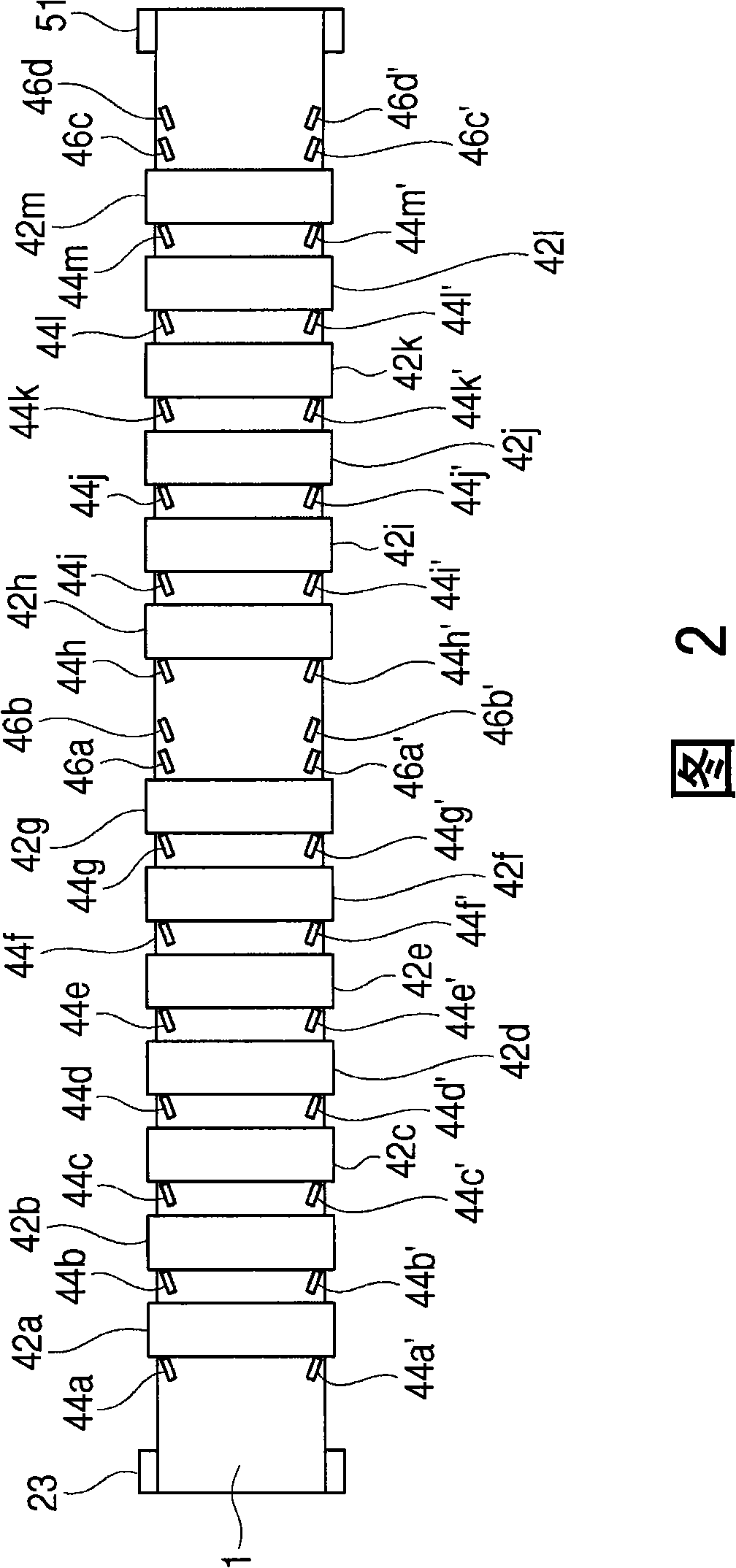

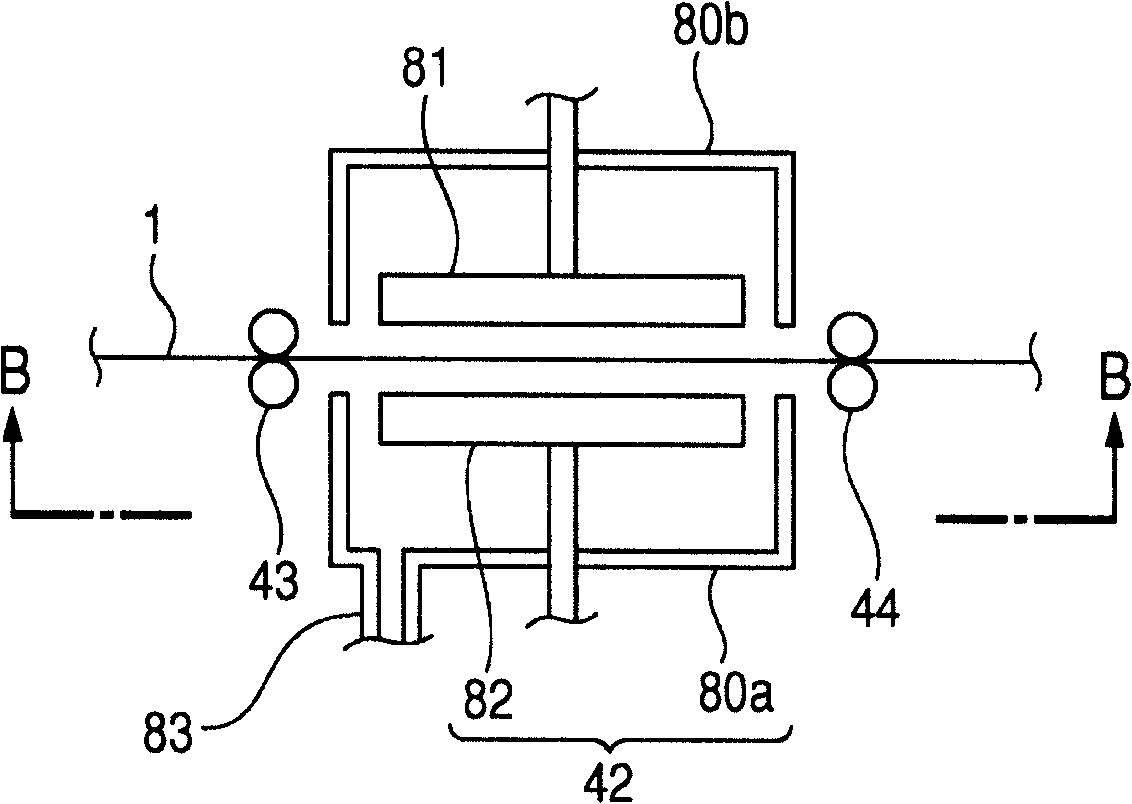

[0032] Figure 1 is a top view of an embodiment of the apparatus of the present invention for manufacturing a thin film laminate. FIG. 2 is a front view cut along line II-II in FIG. 1 . The figures are not drawn to scale.

[0033] As shown in Figures 1 and 2, this equipment for manufacturing film laminates mainly includes: an unwinding unit 10 for feeding a strip-shaped flexible substrate 1, a strip-shaped flexible substrate 1 from the unwinding unit 10 The unwind driving device 20 conveyed to the film forming section 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com