Multi-chip encapsulation construction of large power

A multi-chip packaging and high-power technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as failure, inability to dissipate heat in a timely manner, and large chip current heating, achieving high heat dissipation efficiency, simple packaging and processing technology, Effect of improving reliability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

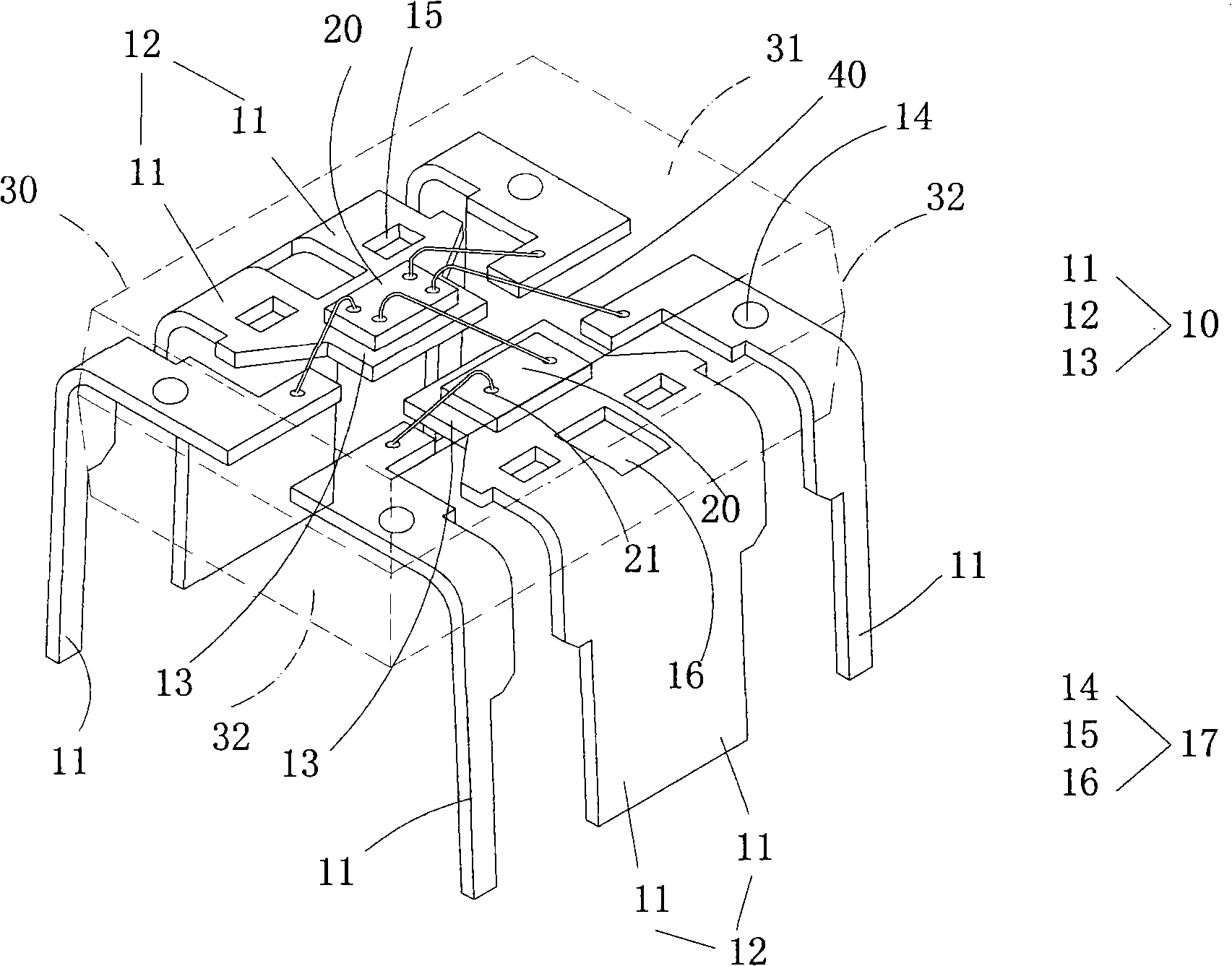

[0027] In order to have a further understanding of the purpose, structure, features and functions of the present invention, the detailed description is as follows in conjunction with the embodiments.

[0028] In order to enable them to be mixed and packaged together without affecting the function definition and geometric shape of standard integrated circuit chips, and comply with current industry specifications for chip packaging, the present invention provides a high-power multi-chip packaging structure. It has a plurality of bearing boards, and each bearing board has pins connected to dissipate heat, which can improve the heat dissipation efficiency of the integrated circuit, improve product reliability, reduce manufacturing cost, and improve product yield.

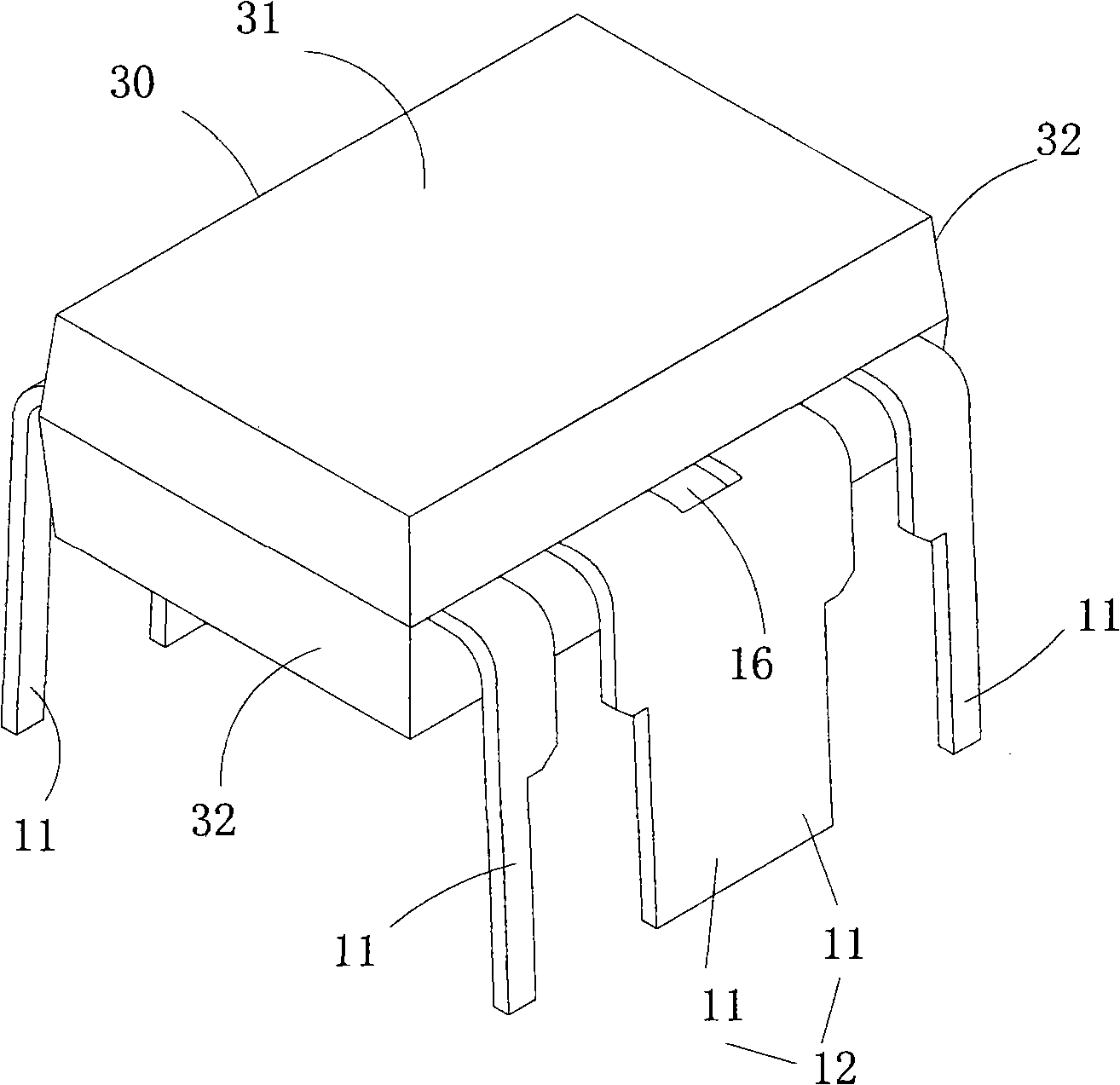

[0029] Such as figure 1 , figure 2 As shown, it is a schematic diagram of a high-power multi-chip packaging structure according to a preferred embodiment of the present invention, including a lead frame 10, two differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com