Permanent magnet wind power generator of combined stator structure

A technology for wind turbines and combined stators, which is applied to the shape/style/structure of the magnetic circuit, and the static parts of the magnetic circuit, etc., can solve the problem of the large span of the integer slot winding stator, the difficulty of embedding the motor winding, and the reduction of starting resistance torque. and other problems, to achieve the effect of convenient wire embedding, small air gap and reducing starting resistance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The detailed structure of the present invention is described in conjunction with the following examples and accompanying drawings.

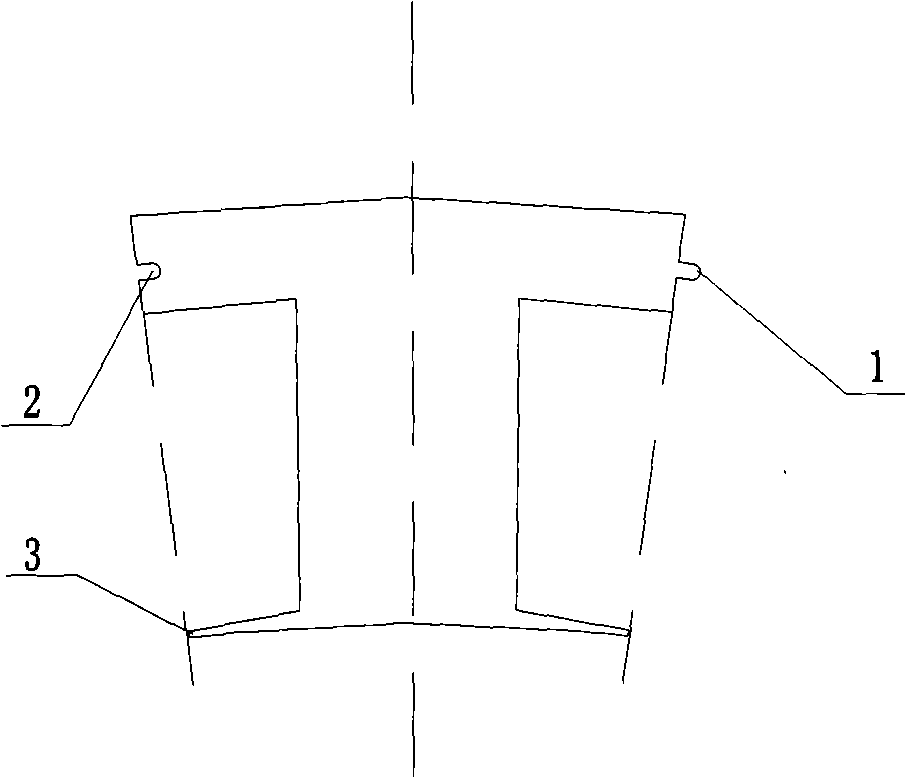

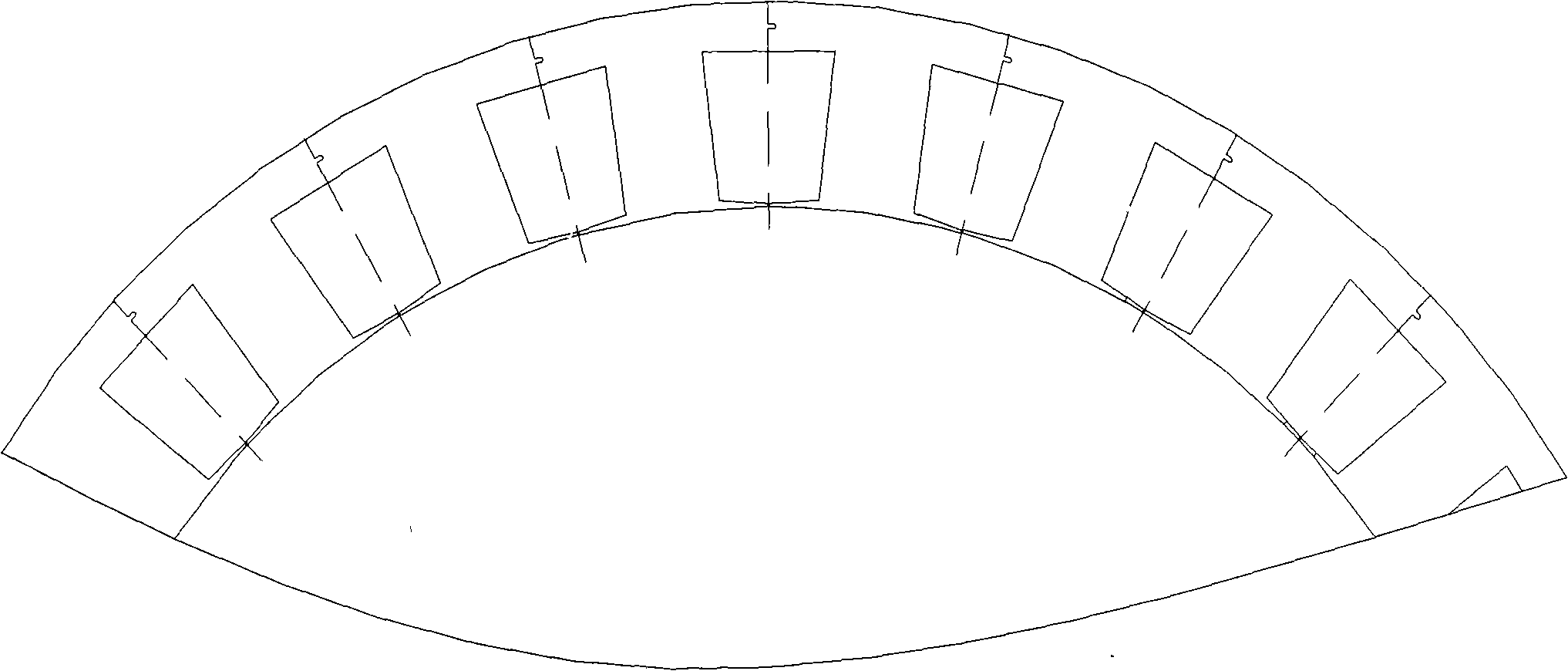

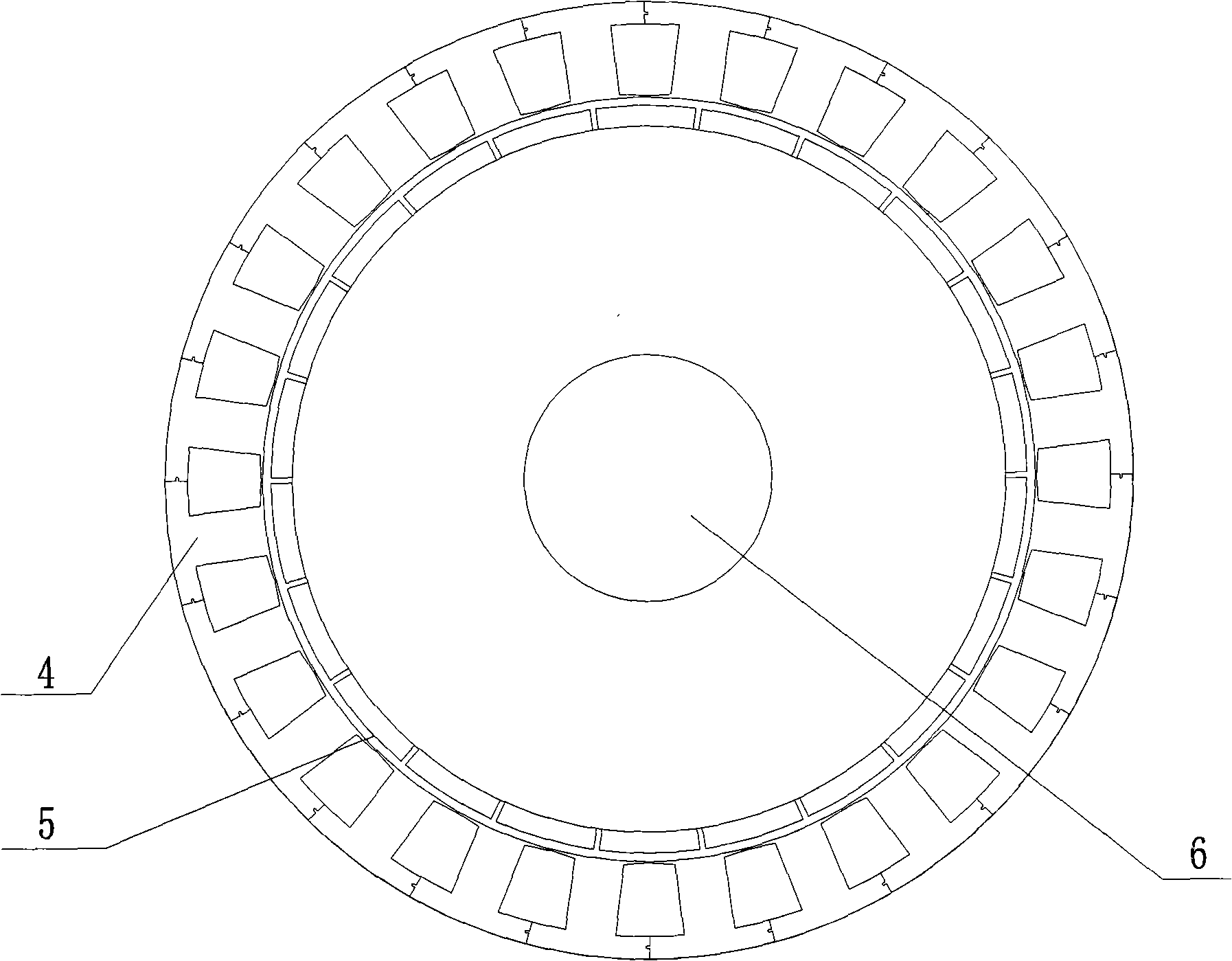

[0014] As shown in the figure, the permanent magnet wind generator includes a stator 4, a rotor 5, a bearing, an end cover and a shaft, wherein the stator 4 is in the shape of a hollow cylinder, and the hollow cylinder is formed by splicing magnetic poles, coils are wound on the magnetic poles, and the magnetic poles are It is formed by stacking punches, the punches are in the shape of "I", the upper and lower edges are arc-shaped, and there are a punching protrusion 1 and a punching groove 2 on both sides of the punching yoke, and the punchings are stacked At the same time as the magnetic pole is formed, the punching protrusion 1 and the punching groove 2 are laminated to form a magnetic pole protrusion and a magnetic pole groove respectively, and two adjacent magnetic poles are joined together by the magnetic pole protrusion and the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com