Temperature-control sealed door of warm-pressing experiment box

A technology for experimental boxes and airtight doors, which is applied in the field of temperature-controlled airtight doors and active temperature-controlled airtight doors. The effect of temperature control speed and high heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

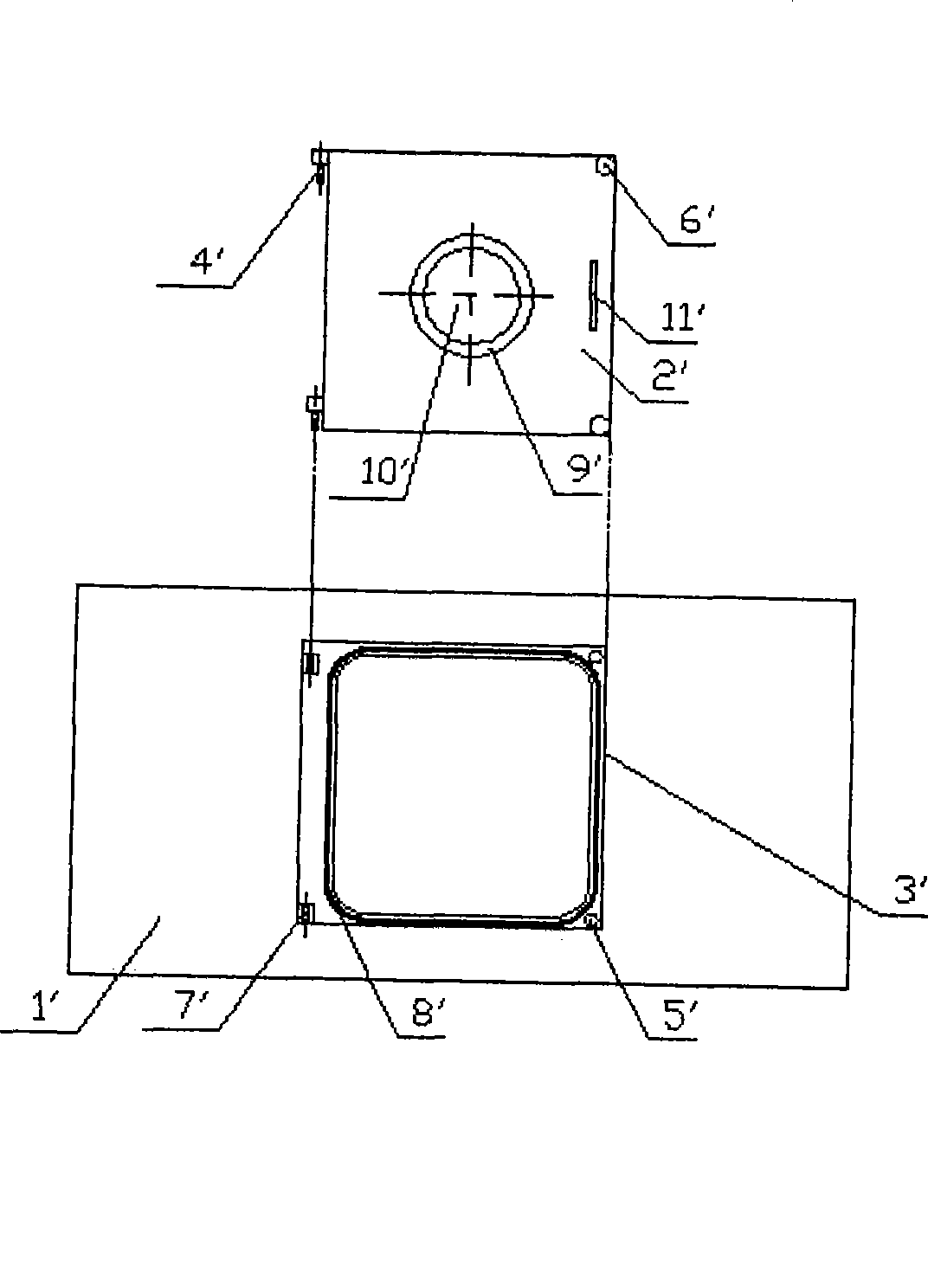

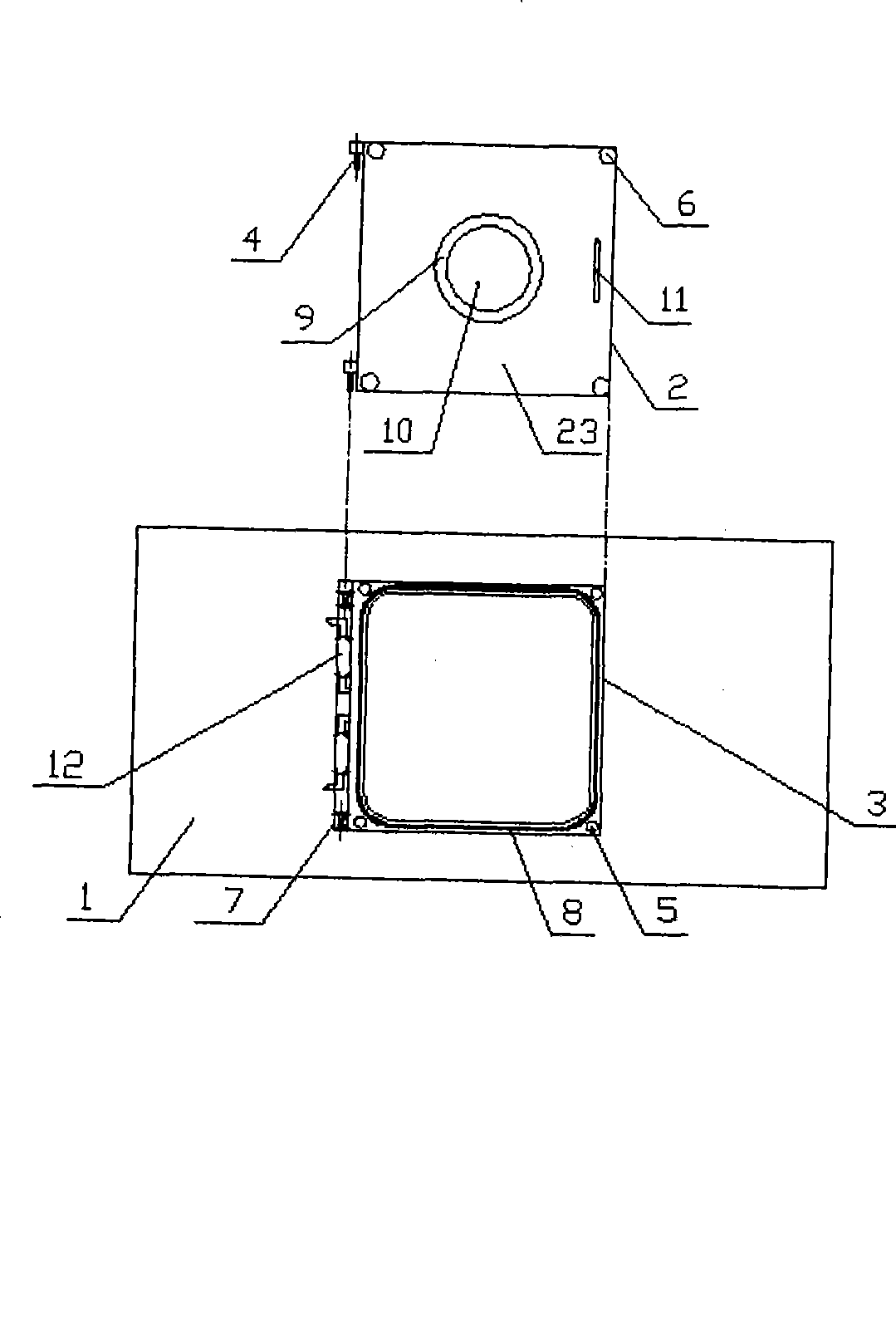

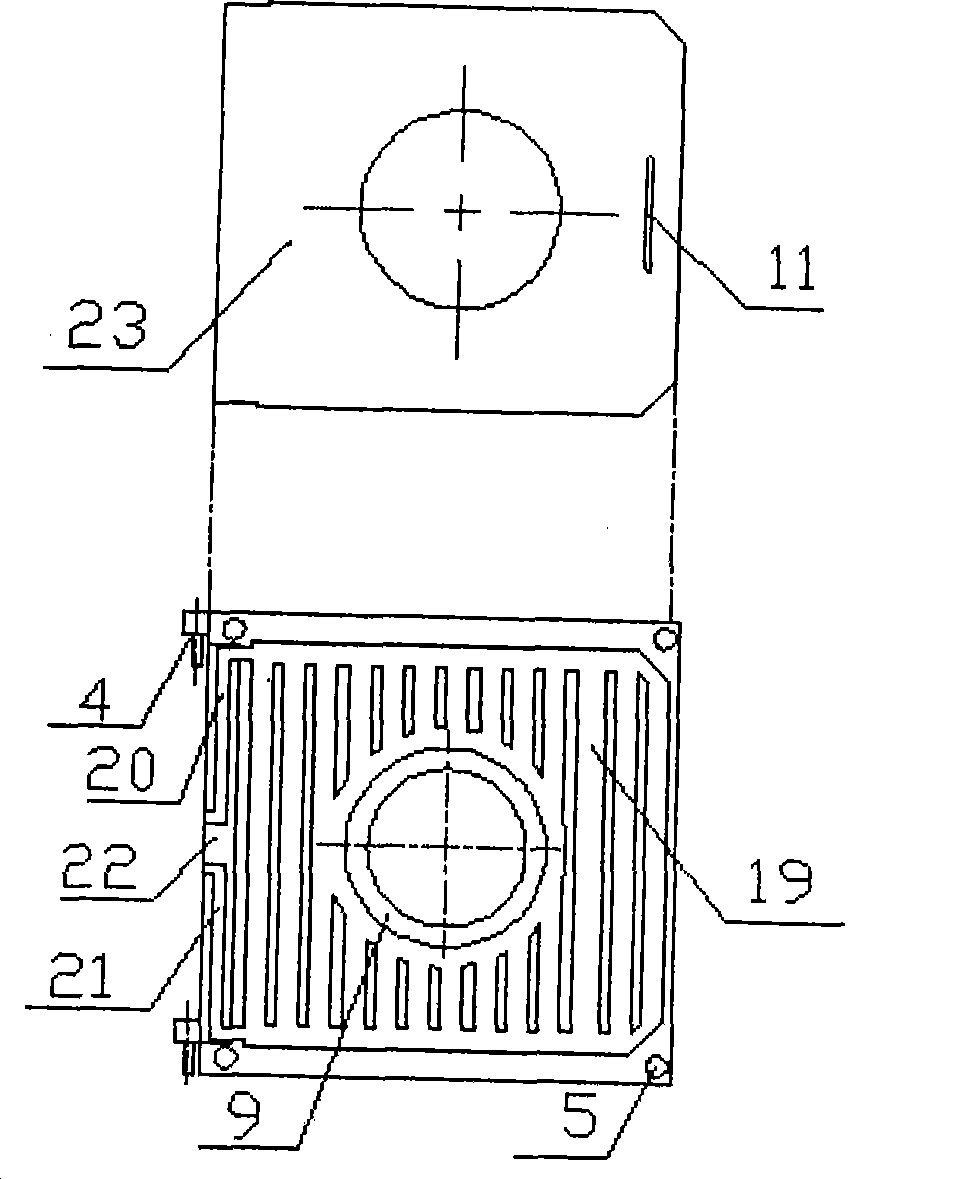

[0033] See figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a temperature-pressure comprehensive experiment box temperature control sealed door, which is composed of a box wall plate 1, a door 2, a door frame 3, a door shaft 4, a door shaft fixing seat 7, a sealing ring 8, and a rotary joint 12; the sealing ring 8 Placed in the door frame 3 with grooves, the door frame 3 is welded in the center of the box wall plate 1, the door 2 is installed in the door shaft fixing seat 7 on the door frame 3 through the door shaft 4 on it, and the rotary joint 12 is equipped with a spring 18 The screws 17 are fastened on the box wall plate 1.

[0034] Wherein, the door 2 is formed by connecting the metal plate 22 provided with the observation window fixing seat 9 and the groove channel 19 with the skin 23. The groove channel 19 in the interlayer of the door wall passes through the liquid input port 20 and the liquid output port. The port 21, enters and exits the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com