Chemical-mechanical grinding device and chemical-mechanical grinding method

A technology of chemical mechanics and grinding methods, which is applied in the direction of grinding machine tools, grinding/polishing equipment, grinding devices, etc., can solve problems such as scratches on the surface of the substrate, and achieve the effect of reducing scratches

Inactive Publication Date: 2010-11-10

SEMICON MFG INT (SHANGHAI) CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention provides a chemical mechanical polishing equipment and a chemical mechanical polishing method to improve the problem that scratches are easily caused on the substrate surface after polishing in the existing chemical mechanical polishing process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

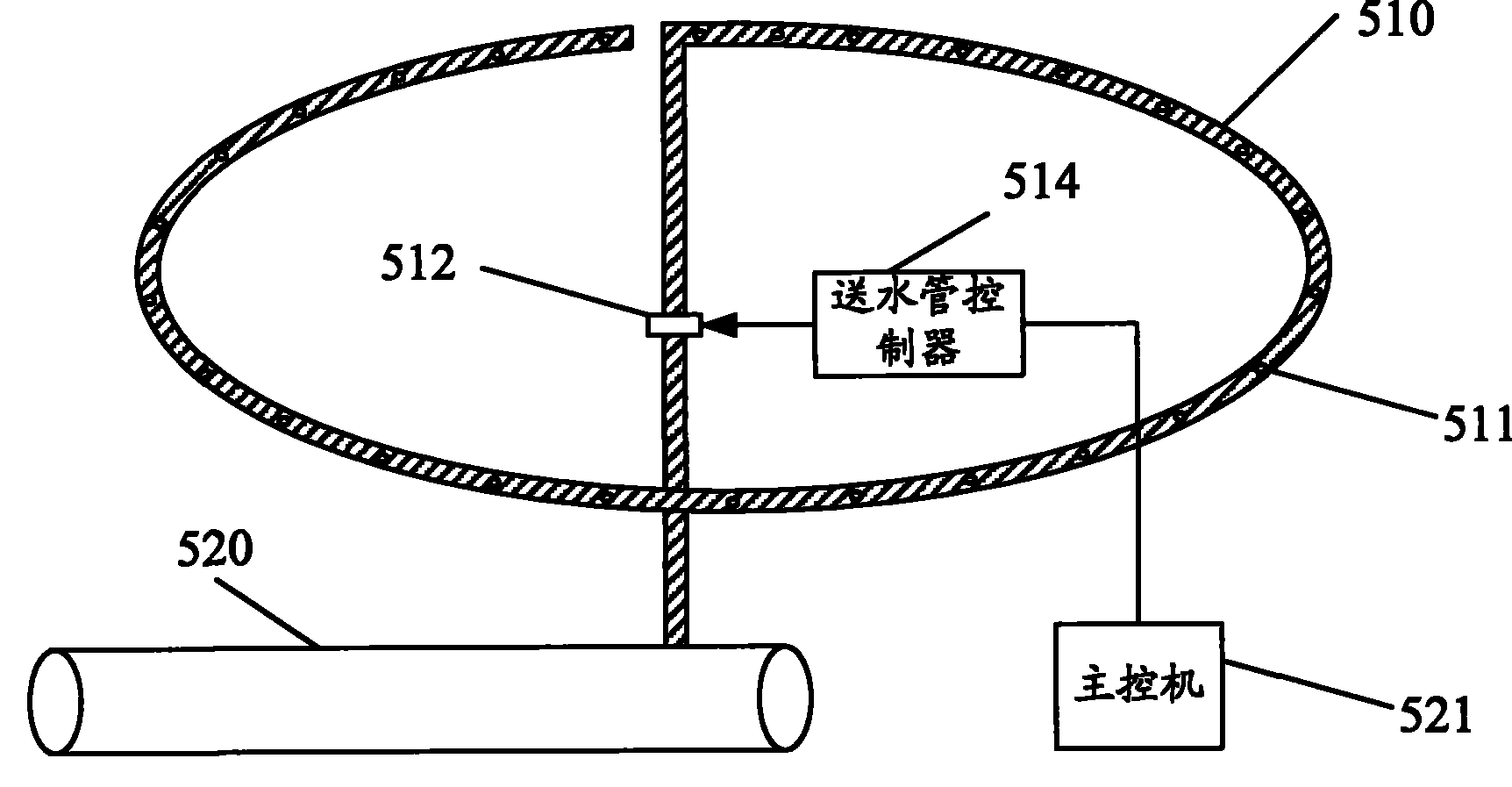

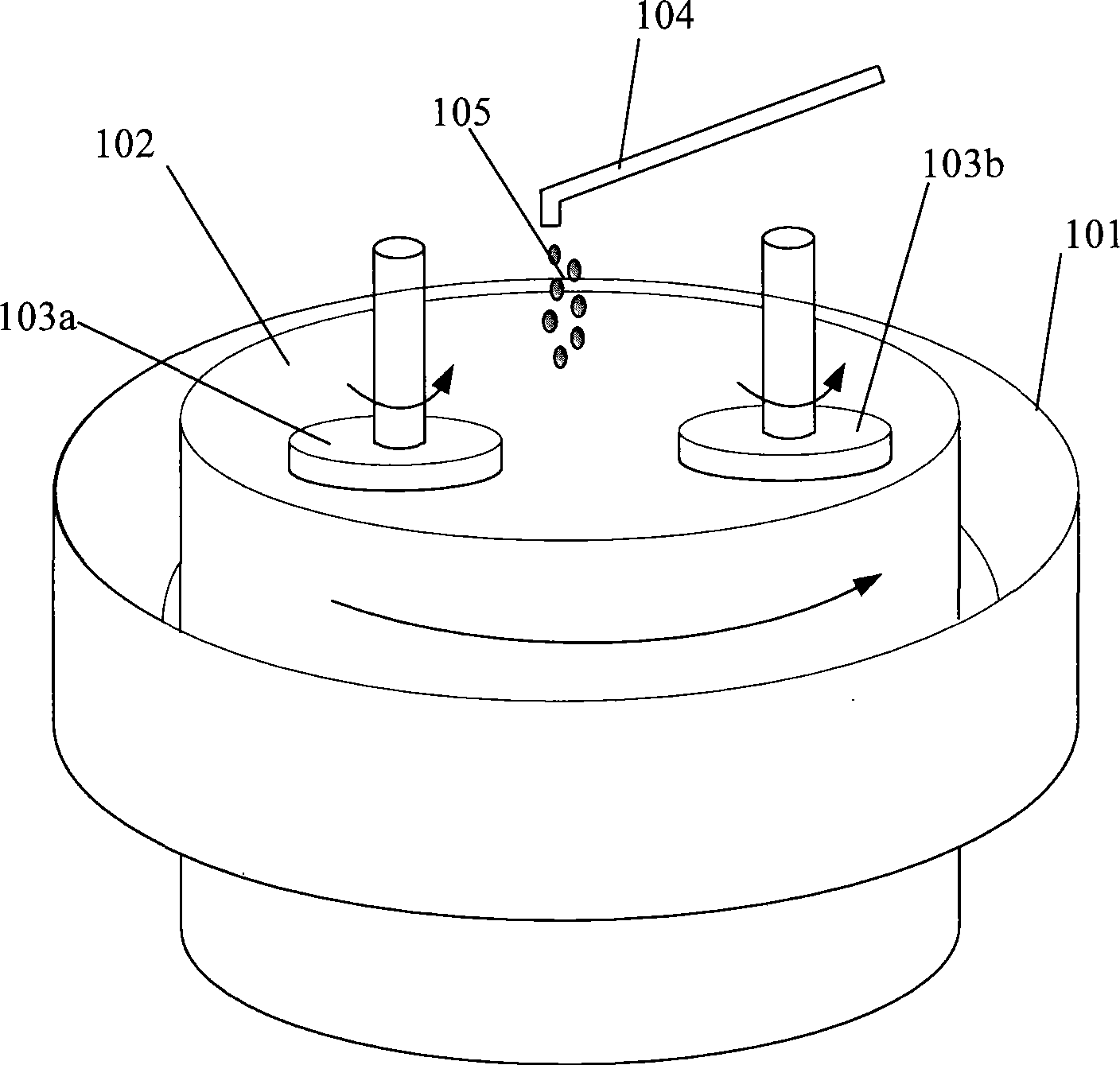

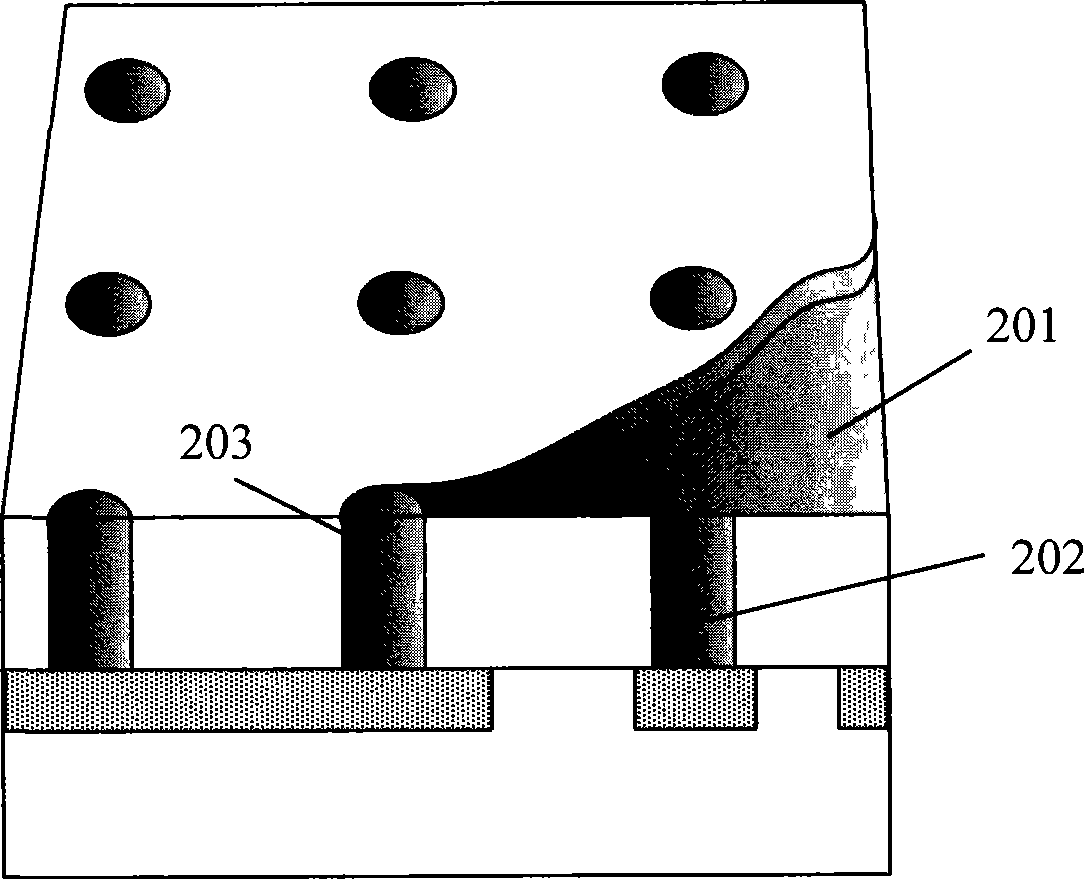

The invention discloses chemical machinery grinding equipment which comprises a casing, a rotating table, a grinding pad, a flushing device and a main control computer, and also a moisture preservation device, wherein, the moisture preservation device is provided with a flow pipe connected with a deionized water pipe, the flow pipe is installed around the inner upper edge of the casing, the flow pipe is provided with a switch to control the open or close state, and a plurality of openings are formed on the side walls of the of the flow pipe facing to the periphery of the rotating table. The invention also discloses the corresponding chemical machinery grinding method. By adopting the chemical machinery grinding equipment and the chemical machinery grinding method, after the grinding is stopped, the moisture preservation can be performed on the periphery of the rotating table of the equipment, and the scratch on the surface of the liner caused by the splashing grinding lubricant after drying can be reduced.

Description

Chemical mechanical polishing equipment and chemical mechanical polishing method technical field The invention relates to the technical field of semiconductor manufacturing, in particular to a chemical mechanical polishing device and a chemical mechanical polishing method. Background technique With the rapid development of ULSI (UltraLargeScaleIntegration), the manufacturing process of integrated circuits has become more and more complex and sophisticated. In order to improve integration and reduce manufacturing costs, the feature size of components (FeatureSize) is getting smaller and the number of components per unit area of the chip is increasing. It is difficult for planar wiring to meet the requirements of high-density distribution of components. Multilayer wiring technology can only be used The vertical space of the chip further increases the integration density of the device. However, the application of multi-layer wiring technology will cause the surface of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B37/04B24B29/00B24B57/00B24B57/02H01L21/304B24B37/34

Inventor 李福洪

Owner SEMICON MFG INT (SHANGHAI) CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com