Method for detecting light intensity distribution of gradient filter and method for enhancing consistency of line width

A light intensity distribution and filter technology, which is applied to the original parts, instruments, optics, etc. used for optomechanical processing, can solve the problems of taking up time for running goods, increasing manufacturing costs, and wasting time, so as to improve working time and reduce The effect of simple cost and detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

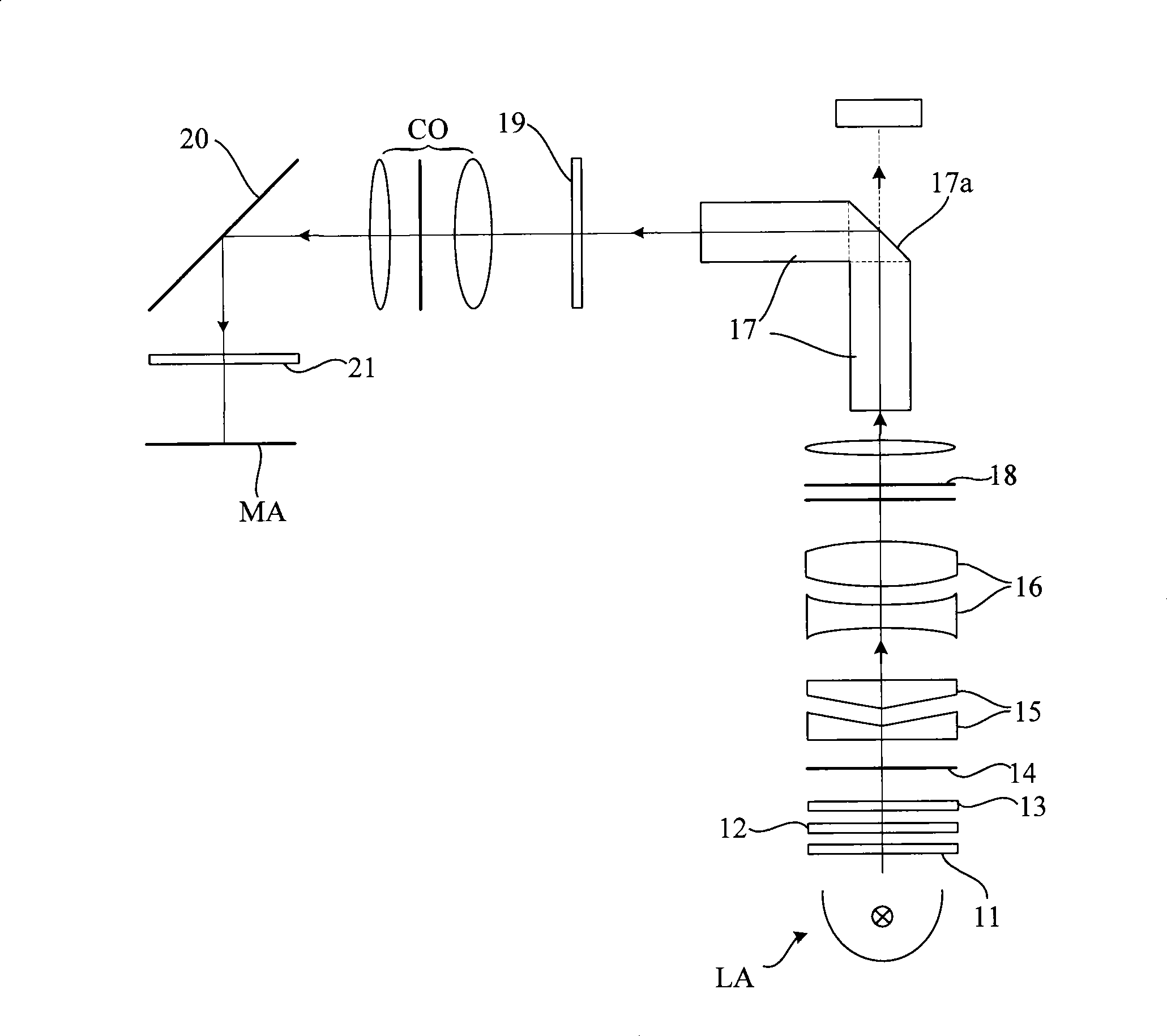

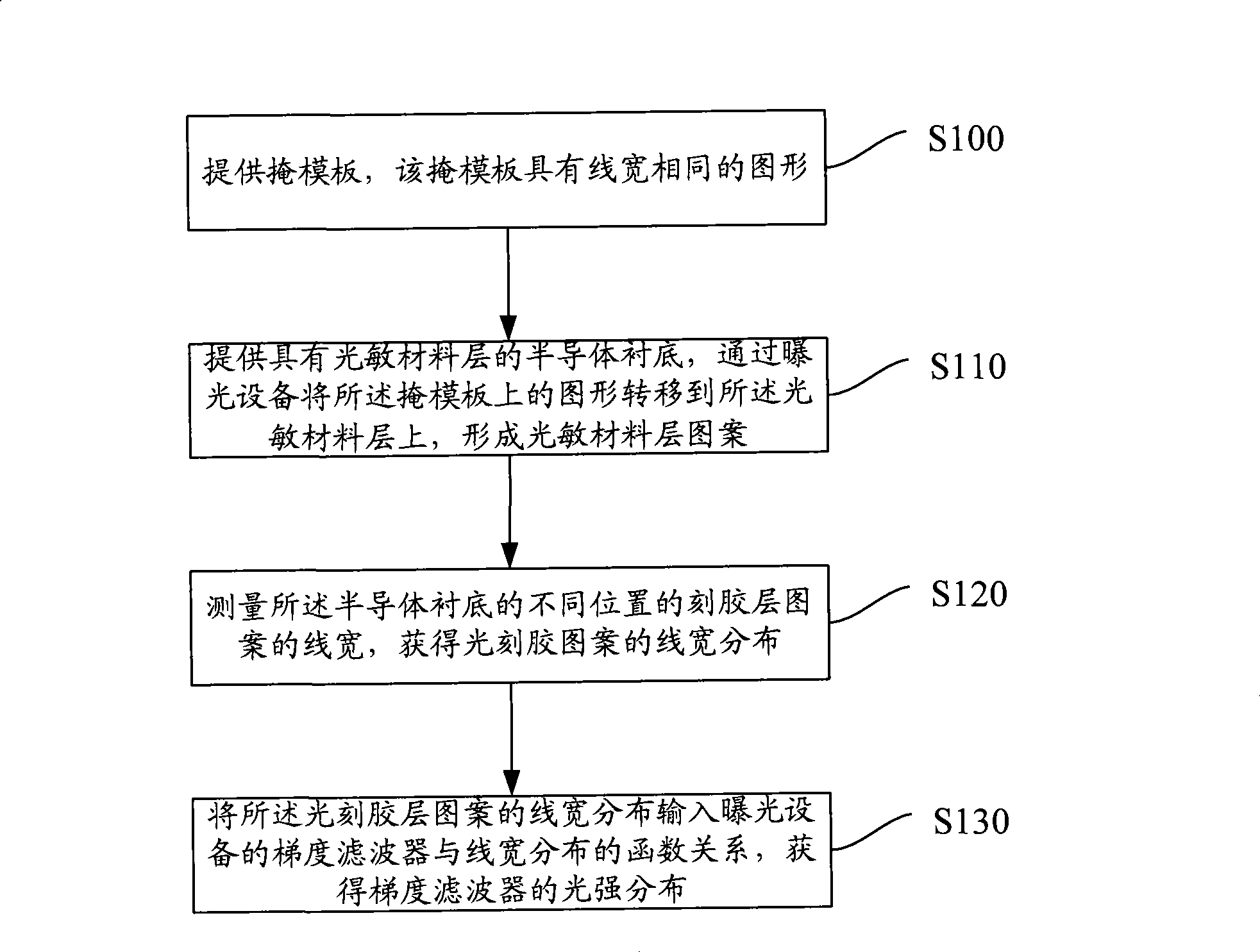

[0049] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

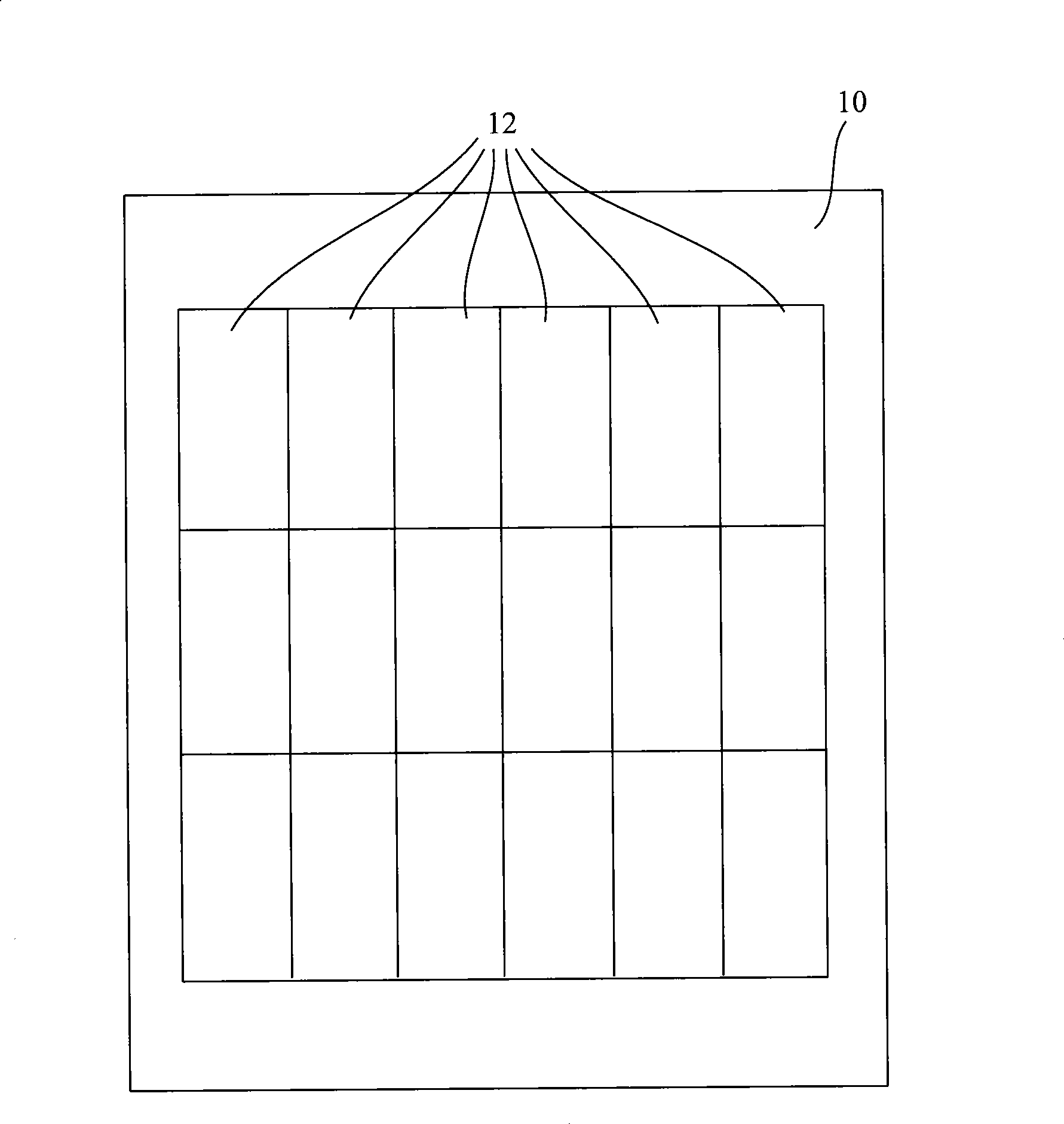

[0050] In the photolithography process, it is necessary to accurately copy the pattern on the mask plate to the photosensitive material of the semiconductor substrate; for the same mask plate, it is necessary to transfer the pattern with the same line width to After being placed on the photosensitive material of the semiconductor substrate, it still has the same line width, that is, the light emitted by the light source needs to be evenly distributed to each area of the mask after passing through the optical system of the exposure equipment.

[0051]Due to the influence of the aberration of the optical system, after the patterns with the same line width at different positions of the exposed mask plate are transferred to the photosensitive material, the line width of the formed pattern is not consistent. Especially due to the large aberra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com