Heat conducting module and manufacturing method thereof

A technology of heat conduction module and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, lighting and heating equipment, cooling/heating device of lighting equipment, etc., and can solve the problem of insufficient bonding strength, loose separation, and flux material cost heat conduction module process cost increase etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and description, and are not intended to limit the present invention.

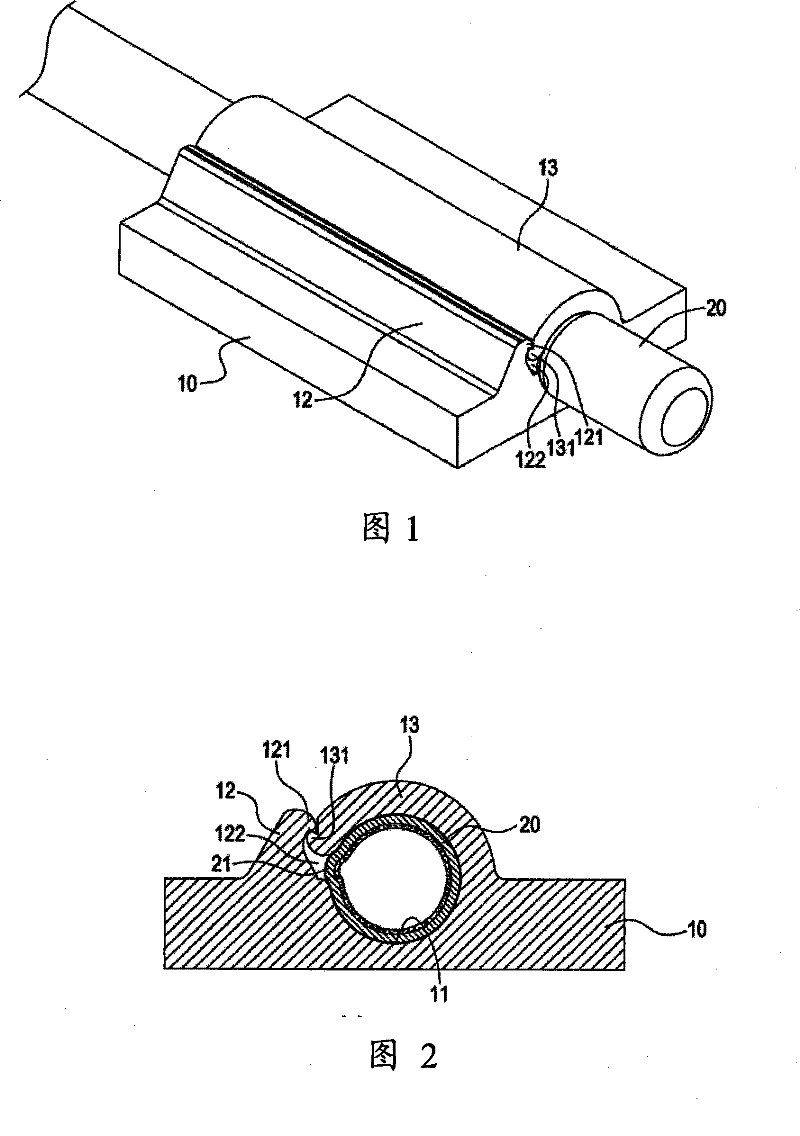

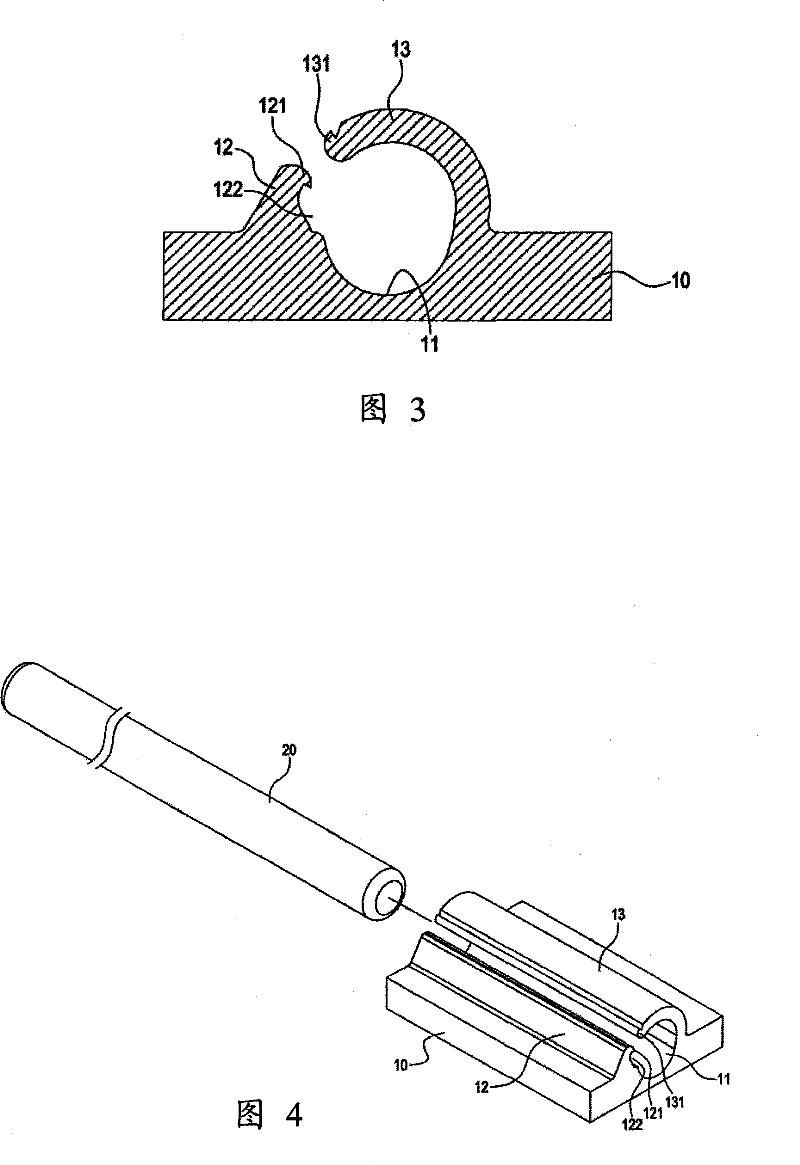

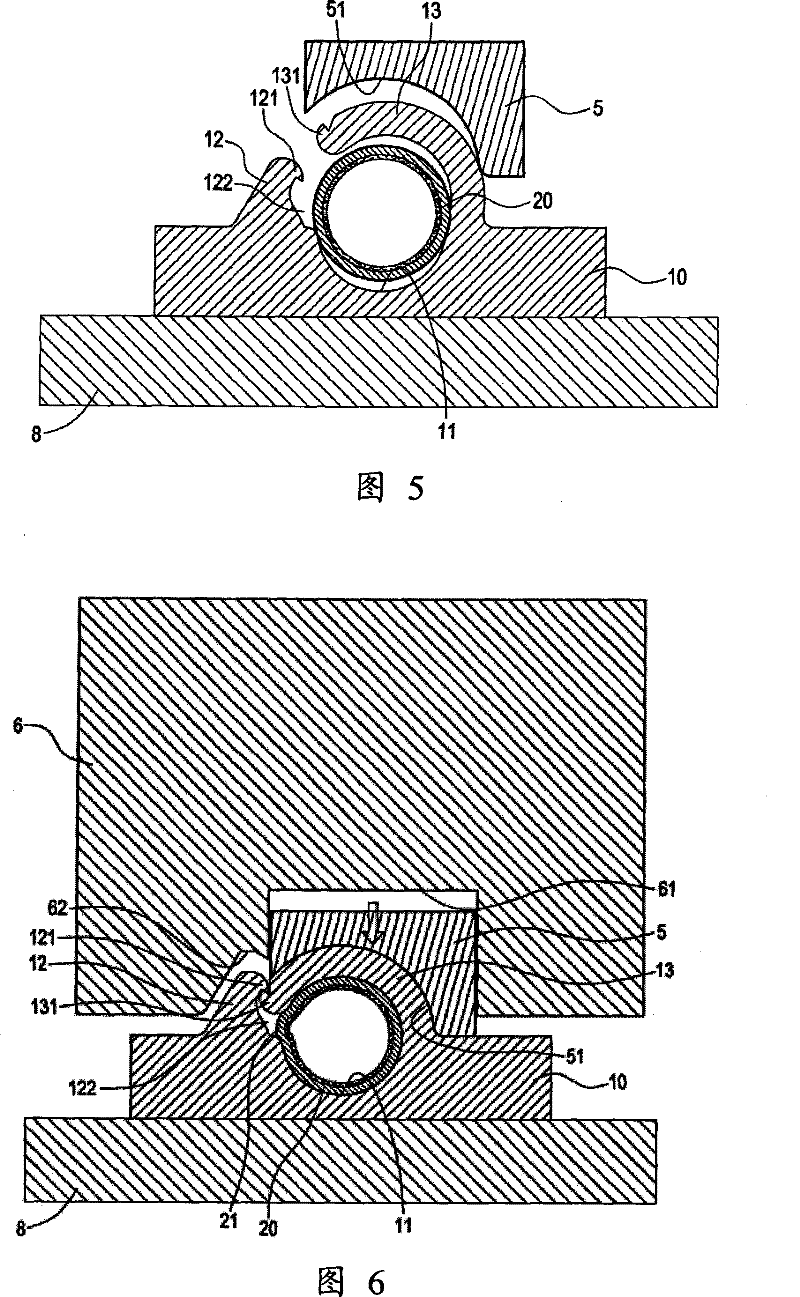

[0021] Please refer to figure 1 and figure 2 As shown, they are respectively a combination schematic diagram and a combination cross-sectional view of the present invention. The present invention provides a heat conduction module, including a heat conduction seat 10 and a heat pipe 20, wherein:

[0022] The heat conduction base 10 can be made of aluminum, copper or other materials with high thermal conductivity. The heat conduction seat 10 of this embodiment is in the shape of a flat plate, and a groove 11 is formed on the top surface thereof. On both sides of the groove 11, a first side wall 12 and a second side wall 13 are respectively extended upwards, the first side wall 12 is a short side wall, and the second side wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com