A kind of mechanized processing method of needle-shaped green tea

A processing method and a needle-shaped technology, which are applied in the field of tea making, can solve the problems that the quality of tea making cannot meet the requirements of famous needle-shaped tea, limit the development of famous needle-shaped tea, high labor intensity, etc., and achieve high tea-making efficiency and production cost. Low, stable tea quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

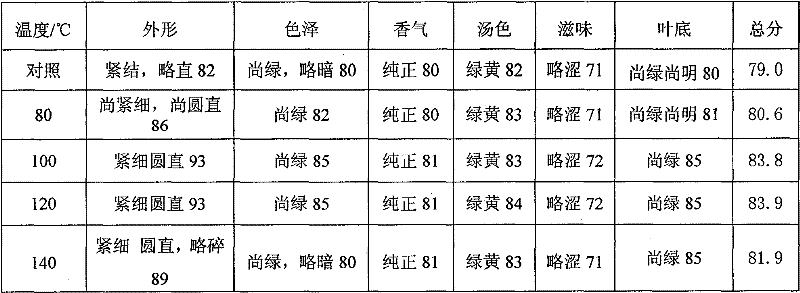

[0022] Example 1: Effect of hot air tight strips on the quality of machine-made needle-shaped tea

[0023] One bud and one leaf of the Fuding Dabai tea variety is used as the raw material. After the fresh leaves are evenly mixed, they are operated according to the technological process of spreading, killing, tightening, shaping, and drying. The greening is carried out in the 6CST-40 type drum continuous greening machine (Zhejiang Green Peak Machinery Co., Ltd.) (temperature 120 ~ 140 ° C), and the tight strips are carried out in the 6CR-35 hot air kneading machine (Zhejiang Green Peak Machinery Co., Ltd.). The shape is carried out in the shaper (6CLZ-60 type slitting machine, Zhejiang Lvfeng Machinery Co., Ltd.) (temperature is about 140 ° C, 150 g of leaves per pot), and finally in the 90 ° C 6HCT-60 tea aroma enhancing machine (Zhejiang Green Peak Machinery Co., Ltd.) drying. Set rolling without heating, kneading at air temperature of 80°C, 100°C, 120°C, and 140°C, and repe...

Embodiment 2

[0027] Embodiment 2: the influence of the number of ribs of the pruning machine on the quality of machine-made needle-shaped tea

[0028] One bud and one leaf of the Fuding Dabai tea variety is used as the raw material. After the fresh leaves are evenly mixed, they are operated according to the technological process of spreading, killing, tightening, shaping, solidifying, and drying. The greening is carried out in the 6CST-40 type drum continuous greening machine (temperature 120~140°C), the tight strip is carried out in the 6CR-35 type hot air kneading machine (time about 20min), and the shape is made in the shaper (6CLZ-60 type) Bar machine) (temperature about 140 ℃, 150g of leaf throwing per pot), solidification is carried out in the 6CZG-60 solidification machine, and the solidification leaves are dried on the 6CHP-2 platform. The number of convex ribs in the pot tank of the forming machine is set to 1, 2, 3, and 5, and each treatment is repeated 3 times. The results show...

Embodiment 3

[0038] Embodiment 3: the optimization of machine-made needle-shaped tea solid process

[0039] One bud and one leaf in the tea garden group is used as the raw material. After the fresh leaves are evenly mixed, they are operated according to the technological process of spreading, killing, tightening, initial drying, shaping, solidifying, and drying. The greening is carried out in the 6CST-40 type drum continuous greening machine (temperature 120 ~ 140 ° C), the tight strip is carried out in the 6CR-35 hot air kneading machine (time about 20 minutes), and the initial drying is carried out in the 6CHW-4 mesh belt dryer The shape is carried out in the 6CLZ-60 reciprocating type machine (temperature 90 ~ 110 ℃, 3 catties of leaves per pot), the solid shape is carried out in the 6CPC-60 solid machine, and finally the 6HCT-60 tea leaves Dry in an aroma enhancing machine (92°C, 30min). On the basis of the single factor experiment (see Table 6 for the factors and level settings of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com