Concentrated seafood juice flavourings and preparation method

A production method and seasoning technology, applied in food preparation, application, food science and other directions, can solve the problems of easy loss of nutrition, poor antioxidant properties, easy loss of flavor, etc., and achieve the effects of increasing appetite, plump taste, and stimulating gastric secretion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment 1: The concentrated seafood sauce seasoning of this embodiment is mainly composed of 3-5 parts of dried sea cucumber, 5-8 parts of dried scallops, 5-8 parts of dried shrimps, 10-13 parts of crabs, 10-13 parts of black scallops by weight. Fish eggs, 10-13 parts of oysters, 0.1-0.2 parts of rice wine, 12-20 parts of minced chicken and 6-10 parts of cyclodextrin.

[0030] The alcohol content of yellow rice wine in this embodiment is 14%~18%.

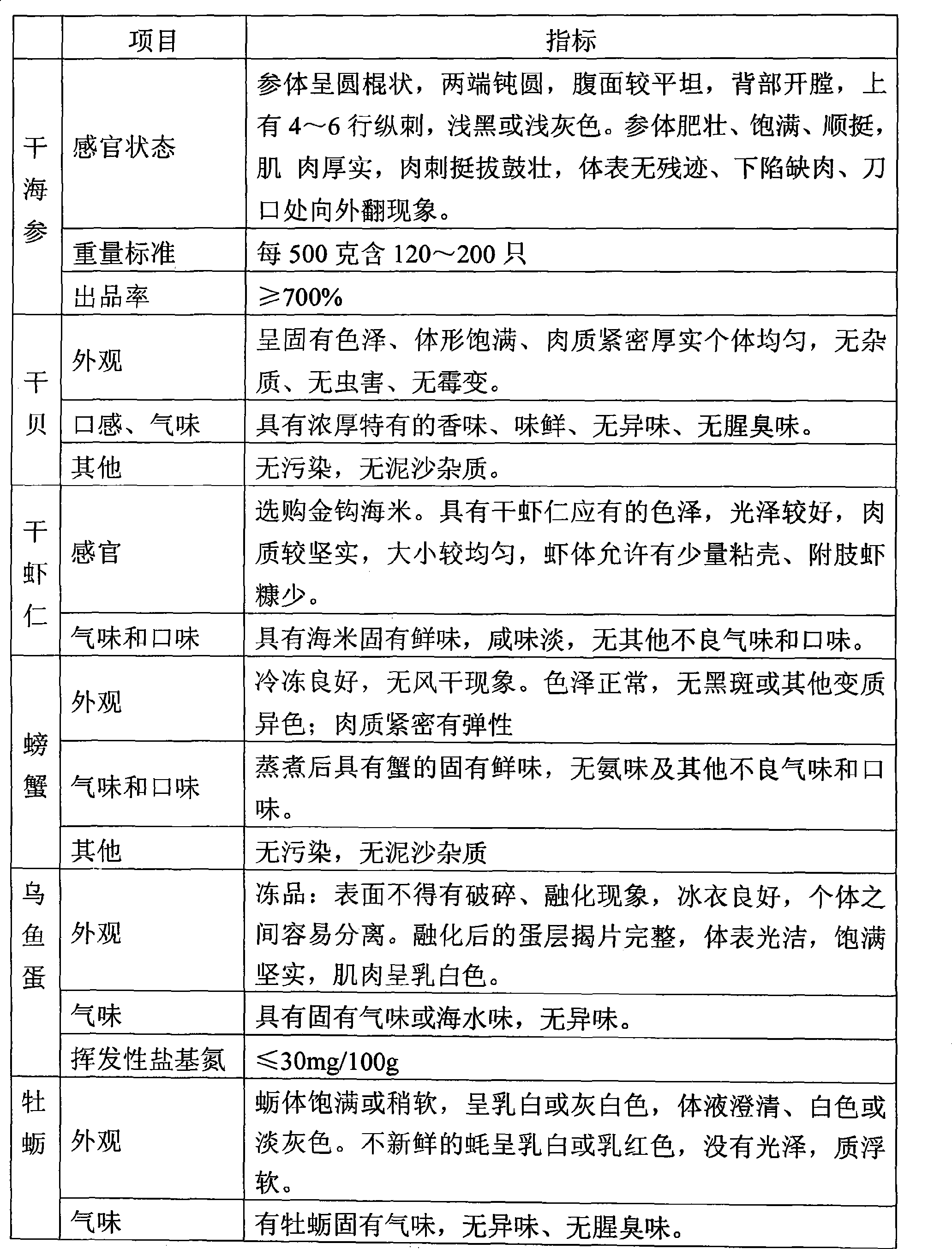

[0031] The material selection standard of this embodiment is as follows:

[0032]

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentrated seafood juice seasoning mainly consists of 3.5 to 4.5 parts of dried sea cucumber, 6 to 7 parts of dried scallops, 6 to 7 parts of dried shrimps, 11 to 7 parts by weight. 12 parts of crabs, 11-12 parts of mullet eggs, 11-12 parts of oysters, 0.12-0.18 parts of rice wine, 14-18 parts of minced chicken and 7-9 parts of cyclodextrin.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the concentrated seafood juice seasoning mainly consists of 4 parts of dried sea cucumbers, 6.5 parts of dried scallops, 6.5 parts of dried shrimps, 11.5 parts of crabs, and 11.5 parts of mullet by weight. Eggs, 11.5 parts of oysters, 0.15 parts of rice wine, 16 parts of minced chicken, and 8 parts of cyclodextrin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com