Piezoelectric type ultrasonic transducer driving power

An ultrasonic transducer and drive power technology, applied in the field of electronics, can solve the problems of reduced bonding efficiency, poor bonding quality, and inability to change the excitation frequency in a timely and accurate manner, achieving fast phase-locking speed, high speed, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

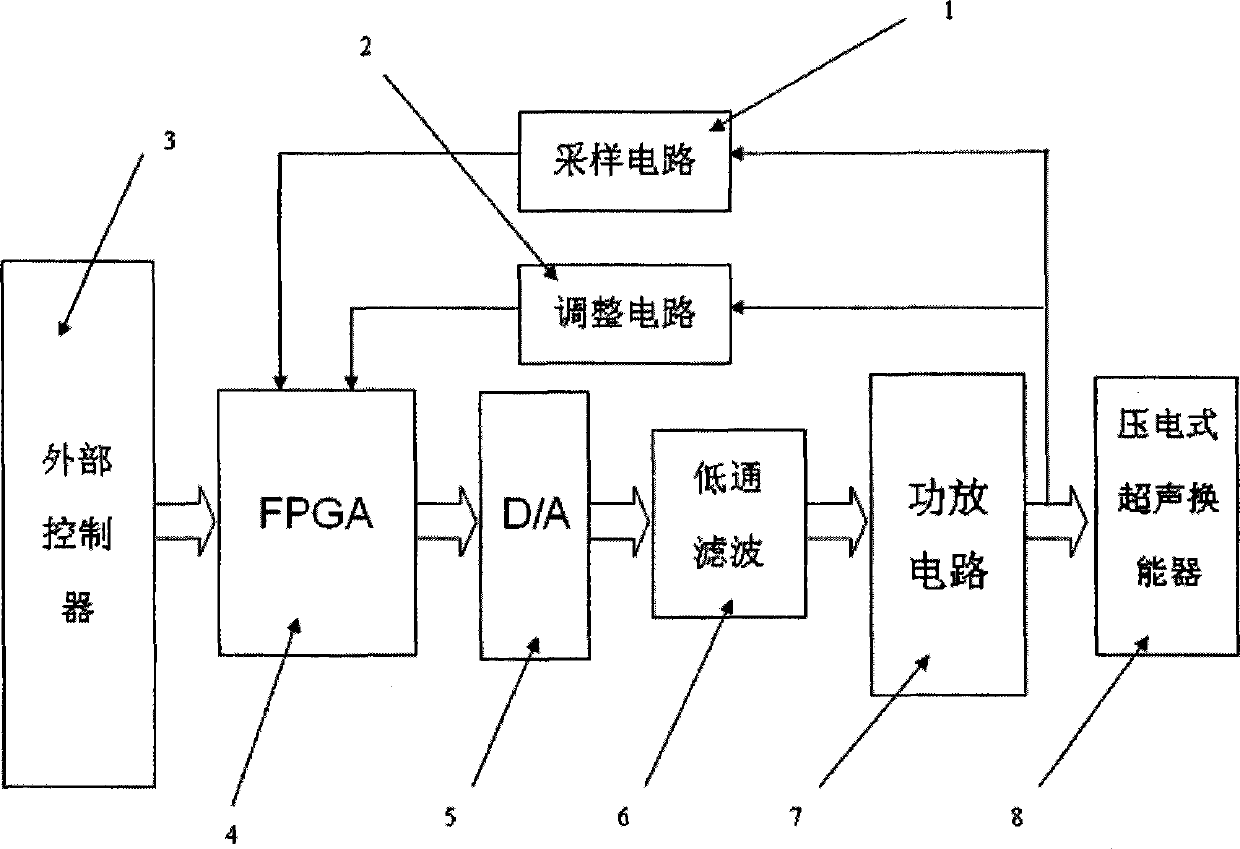

[0027] Such as Figure 2~4 As shown, the driving power supply of the piezoelectric ultrasonic transducer consists of a sampling circuit 1, an adjustment circuit 2, an external controller circuit 3, an FPGA-based processor circuit 4, a D / A conversion circuit 5, a low-pass filter 6, and a power amplifier The circuit 7 etc. are composed.

[0028] The external controller circuit (such as a single-chip microcomputer) sends a pulse control signal to the FPGA, and the FPGA starts to work after receiving the pulse signal;

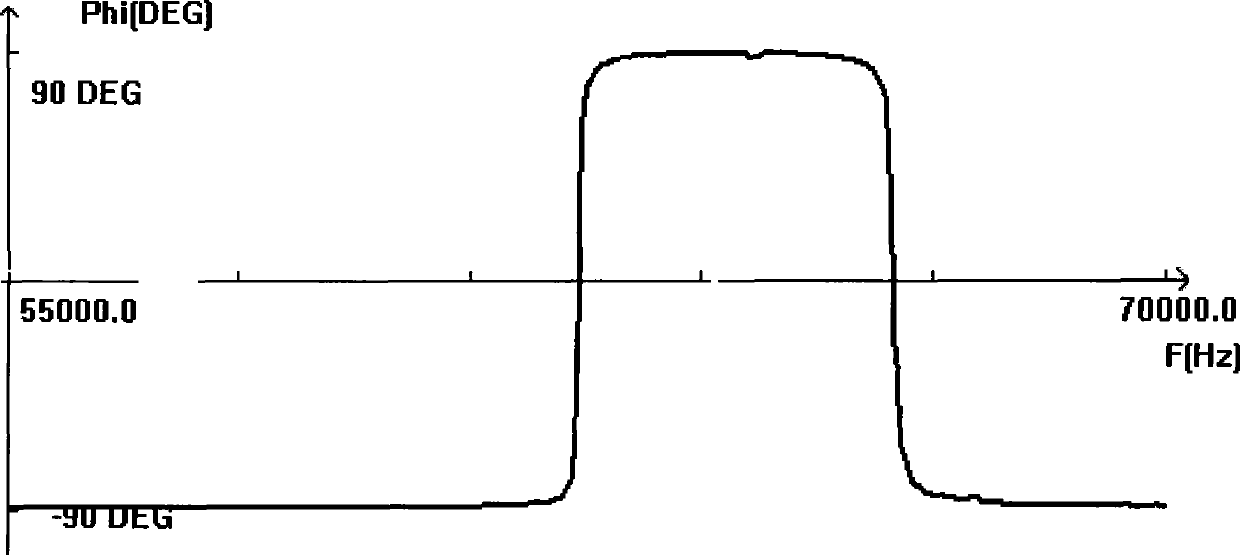

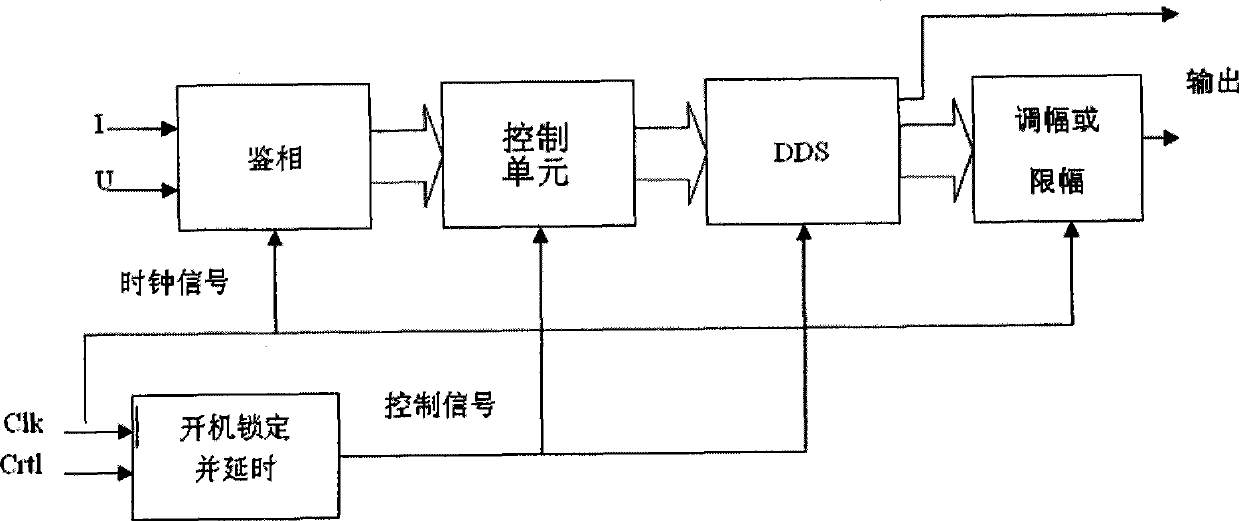

[0029] Such as image 3 As shown, FPGA integrates phase identification, phase locking, DDS function and PID frequency tracking algorithm (the unit to realize the algorithm is image 3 The control unit in the control unit), DDS is the direct digital frequency synthesizer, first load and register the input frequency control word; through the internal phase accumulator, the phase of the frequency control word is accumulated in each clock cycle to obtain a phase valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com