Non-aqueous secondary battery

A non-aqueous secondary battery, positive electrode current collector technology, applied in the direction of secondary batteries, non-aqueous electrolyte battery electrodes, battery electrodes, etc., can solve the problem of inability to ensure capacity, and achieve the effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073]

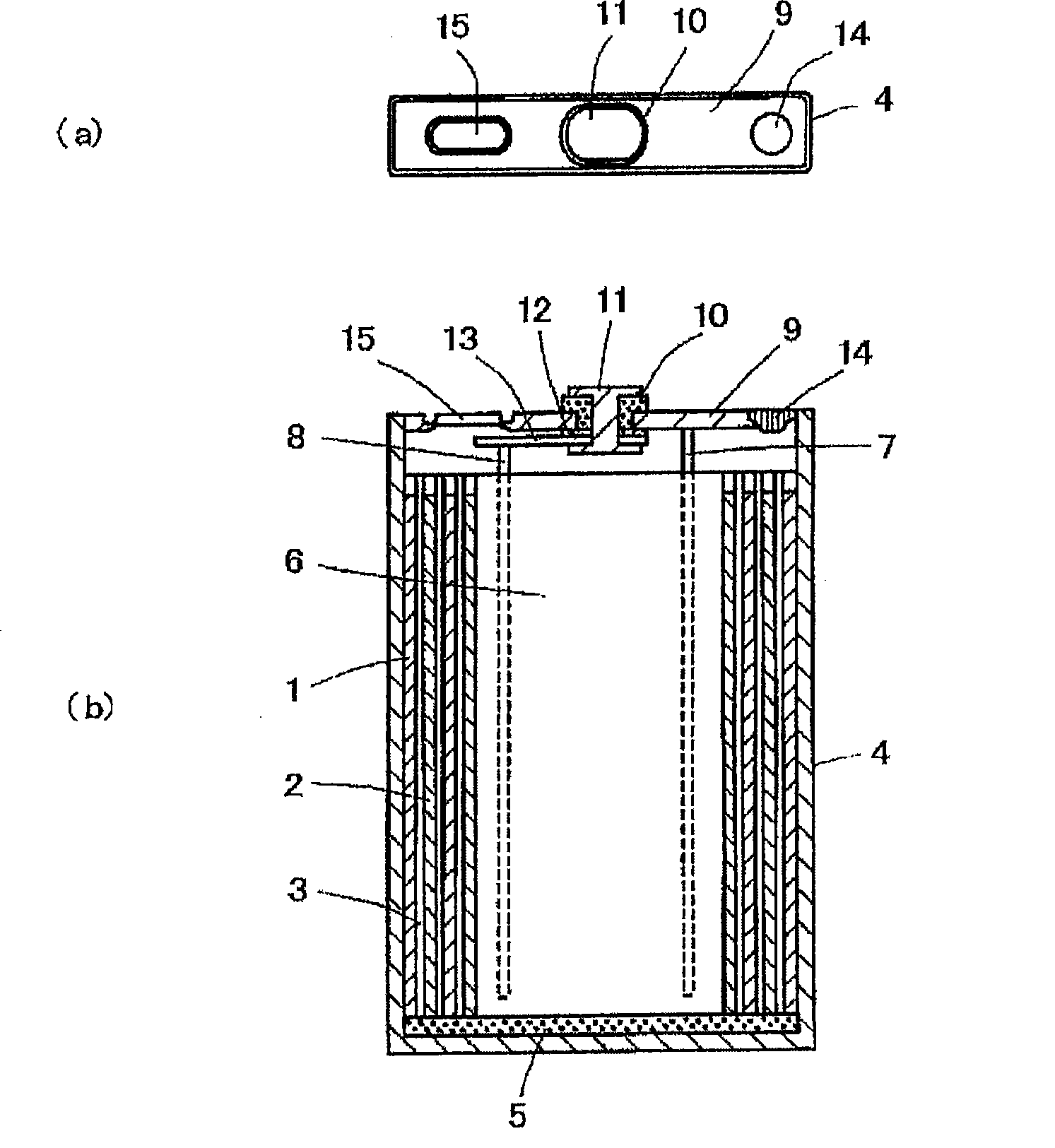

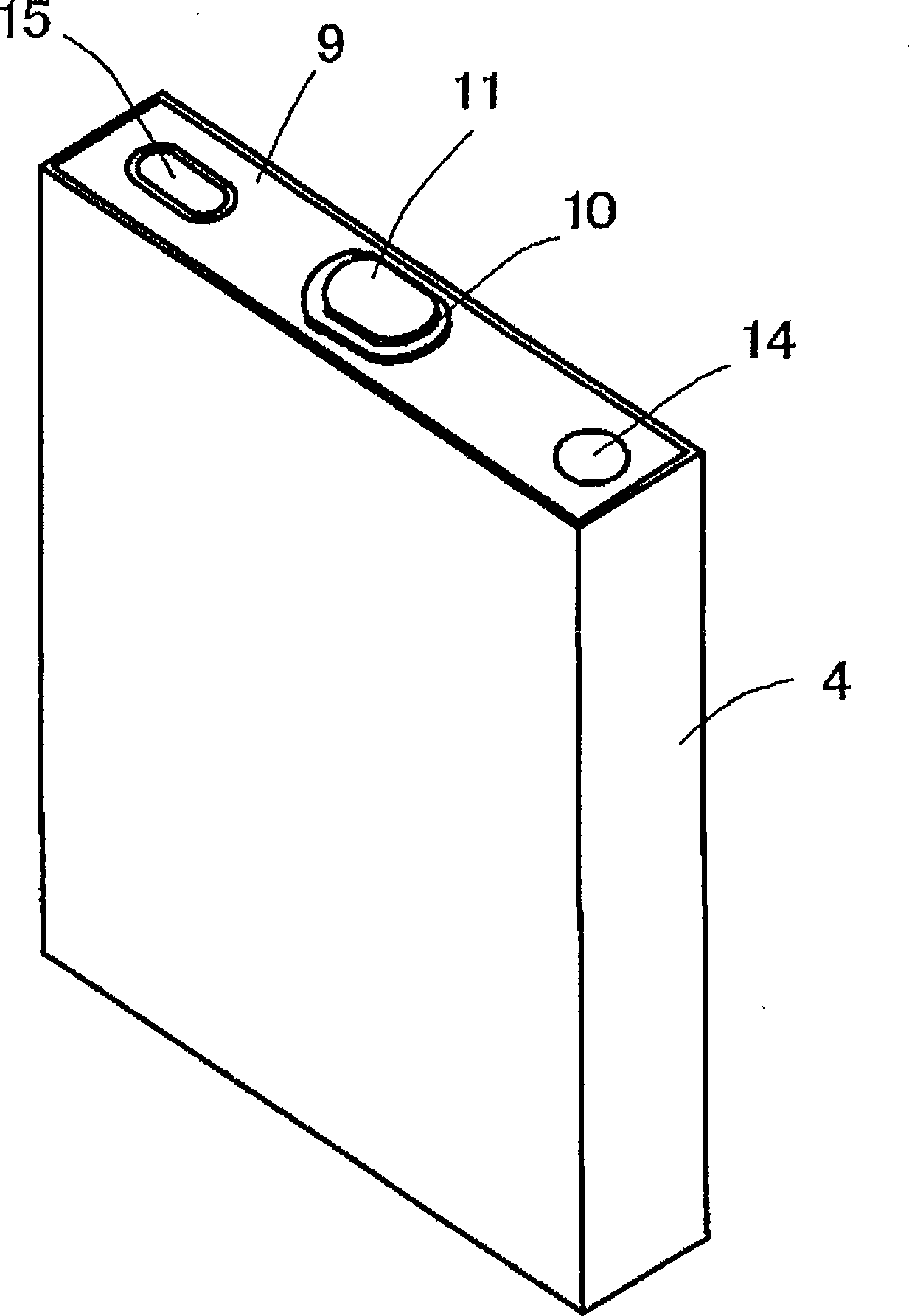

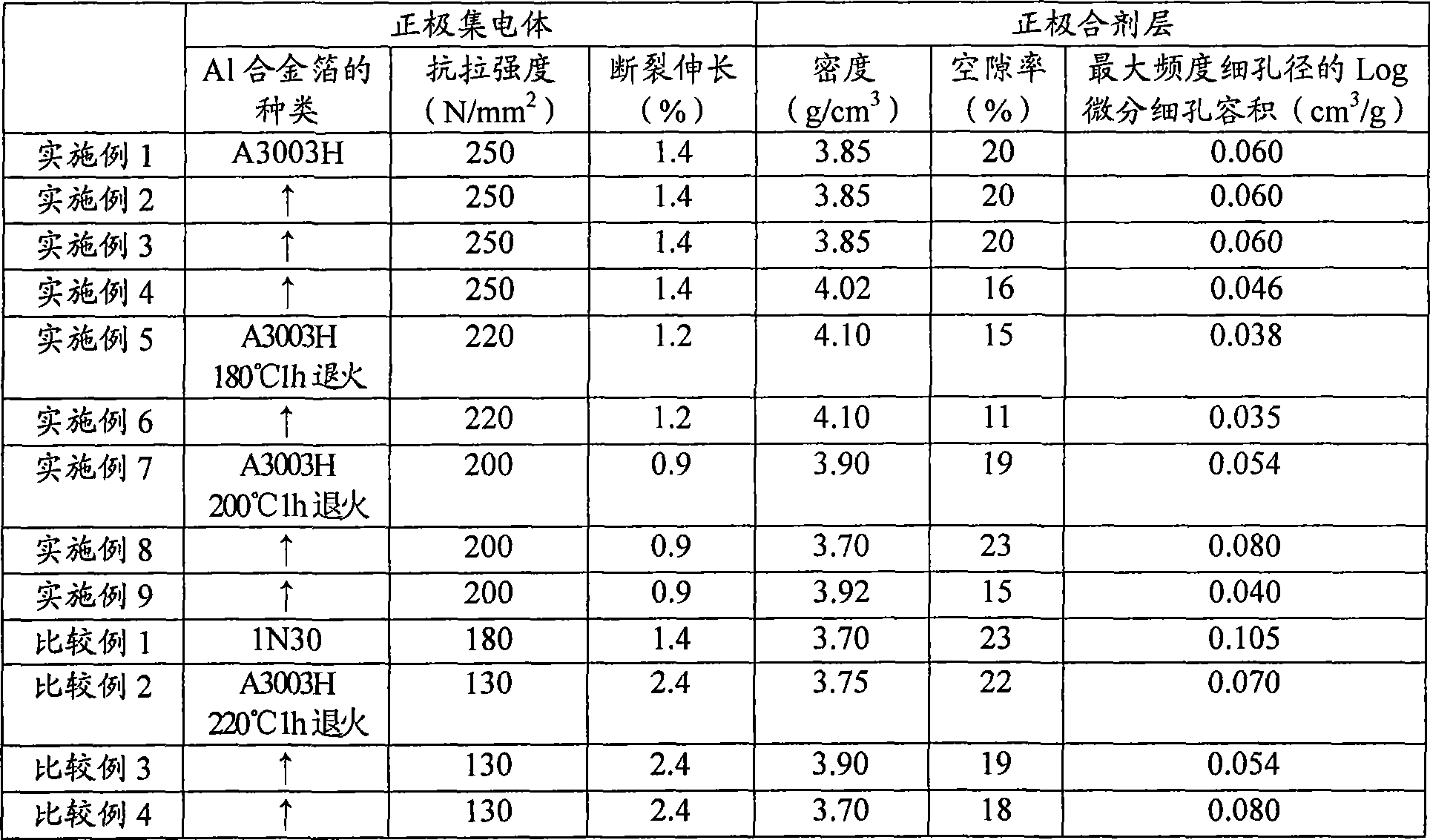

[0074] 97% by mass of lithium cobaltate (average particle size: 12 μm) as an active material, 1.5% by mass of acetylene black as a conductive additive, 1.5% by mass of polyvinylidene fluoride (PVDF) as a binder, and 1.5% by mass of polyvinylidene fluoride (PVDF) as a solvent NMP prepares a composition containing a positive electrode mixture. The preparation of the composition containing the positive electrode mixture is carried out as follows. Dissolve PVDF in NMP in advance, add the above-mentioned active material and acetylene carbon black to the solution, and further add NMP while stirring, and fully disperse it. Adjust viscosity. Use an applicator to evenly coat the composition containing the positive electrode mixture at a thickness of 12 μm and a tensile strength of 250 N / mm 2 , Both sides of the Al alloy foil made of A3003H with an elongation at break of 1.4%, and then rolled with a roll press under the conditions of a roll temperature of 100°C and a pressur...

Embodiment 2

[0085] Adjust the width and length of the electrodes and separators, and operate in the same manner as in Example 1 except that the wound electrode body produced is inserted into a square (width / thickness ratio: 1.7) battery with a width of 17 mm, a thickness of 10 mm, and a height of 65 mm. A non-aqueous secondary battery was produced in the same manner as in Example 1 except for the case (outer body).

Embodiment 3

[0087] Adjust the width and length of the electrodes and separators, except that the operation is the same as in Example 1, and the fabricated wound electrode body is inserted into a square (width / thickness ratio: 10.0) battery with a width of 40 mm, a thickness of 4 mm, and a height of 50 mm. A non-aqueous secondary battery was produced in the same manner as in Example 1 except for the case (outer body).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com