Black leather tanning method

A kind of tanning and leather technology, applied in the direction of small raw hide/big raw hide/leather/fur treatment, tanning treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, etc., which can solve the problem of large K/S curve fluctuations, Problems such as leather color difference and simultaneous dyeing of black leather have not been realized, and the effects of shortening the production cycle, fine grain, and excellent color fastness are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, plant-chromium-iron (T-Cr-Fe) process tanning, using chestnut extract 3% (W / W), powdery chrome tanning agent equivalent to Cr 2 o 3 1.0% (W / W), iron tanning agent equivalent to Fe 2 o 3 0.3% (W / W), according to the following process steps:

[0056] 1. Make pickling bare hide with the conventional process of tanning. Weigh the pickled bare hide, and use 150% of the weight obtained as the benchmark for the amount of water and chemical materials used in steps 2-4.

[0057] 2. Deacidification. Add normal temperature tap water 100% (W / W) to the drum, add salt 10% (W / W), rotate the drum to dissolve the salt, add pickled skins into the drum, start rotating the drum, and the total time of rotation for 90 minutes. Use the methyl orange indicator to check that the incision of the skin plate is yellow, and the pH value of the operating solution should be in the range of 4.5-5.0.

[0058] 3. First add tanning agent 1 for initial tanning. The tanning agent 1 is...

Embodiment 2

[0065] Embodiment 2, plant-chromium-iron process tanning, using chestnut extract 8% (W / W), powdery chrome tanning agent equivalent to Cr 2 o 3 2.2% (W / W), iron tanning agent equivalent to Fe 2 o 3 1.3% (W / W), according to the following process steps:

[0066] 1. Make pickling bare hide with the conventional process of tanning. Weigh the pickled bare hide, and use 150% of the weight obtained as the benchmark for the amount of water and chemical materials used in steps 2-4.

[0067] 2. Deacidification. Add normal temperature tap water to the drum, add NaCl 10% (W / W, percentage by weight), rotate the drum to dissolve the NaCl, add the pickled skins into the drum, and start to rotate the drum. The total rotation time was 150 minutes. Use the methyl orange indicator to check that the incision of the skin plate is yellow, and the pH value of the operating solution should be in the range of 4.5-5.0.

[0068] 3. First add tanning agent 1 for initial tanning. The tanning agent ...

Embodiment 3

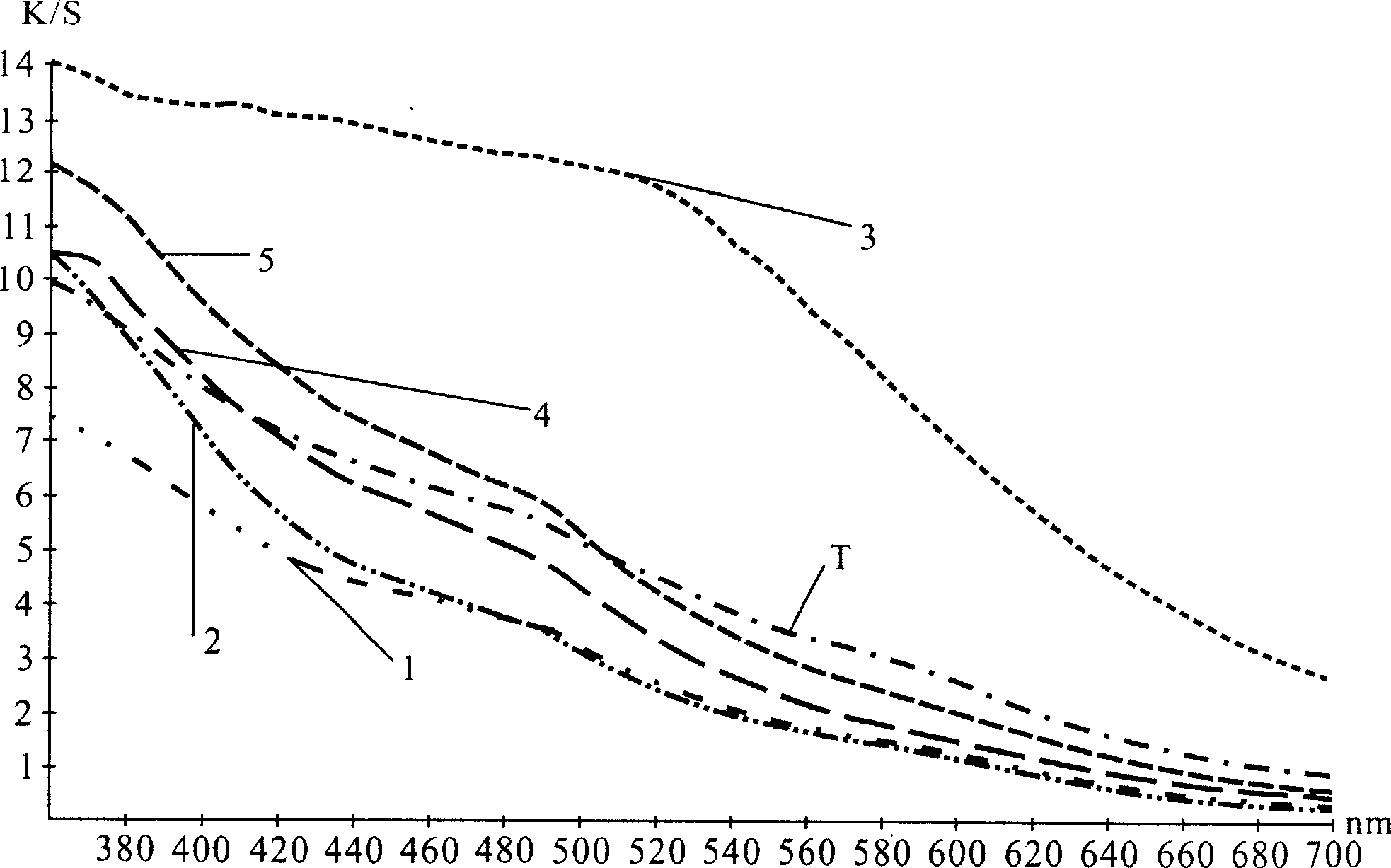

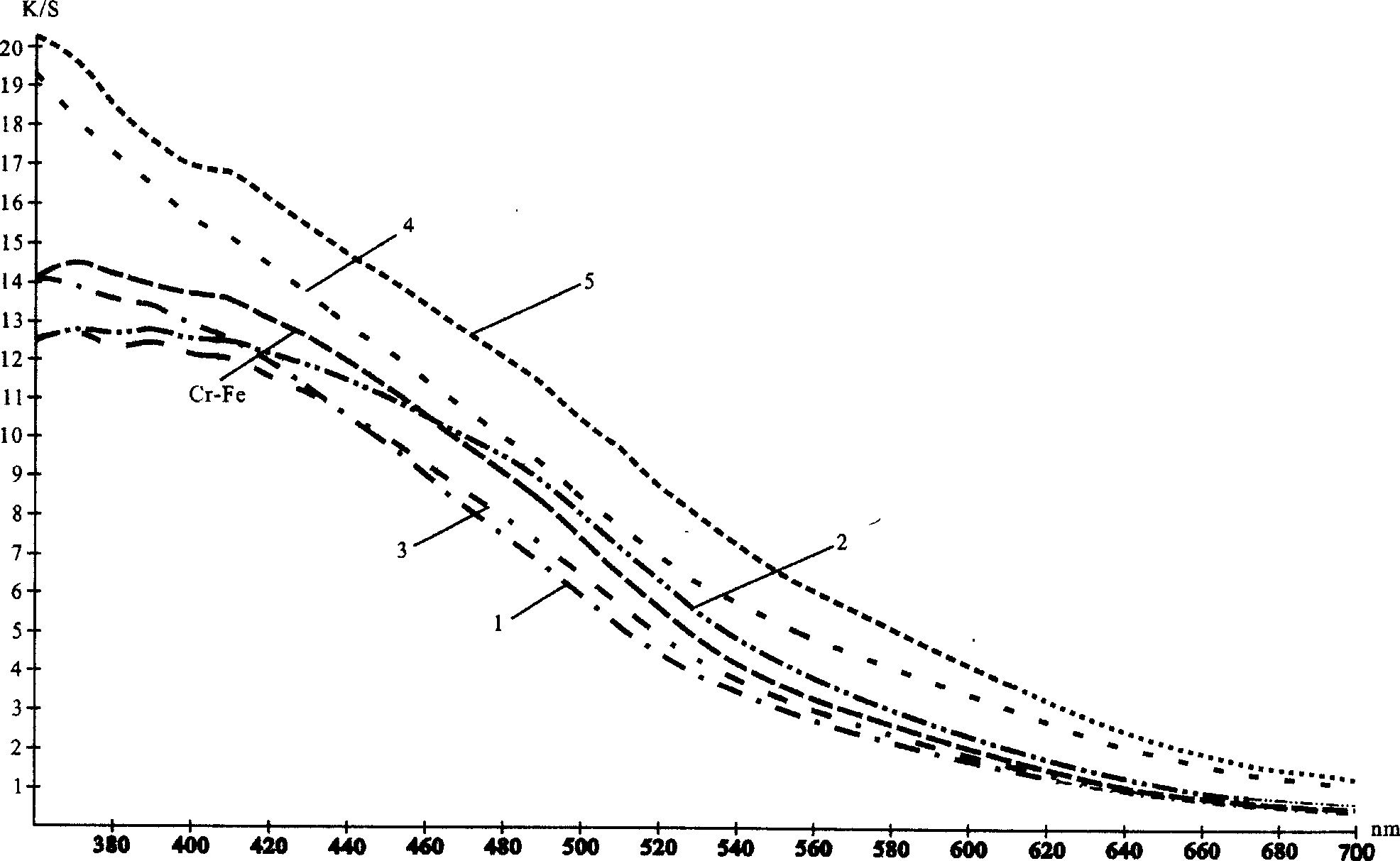

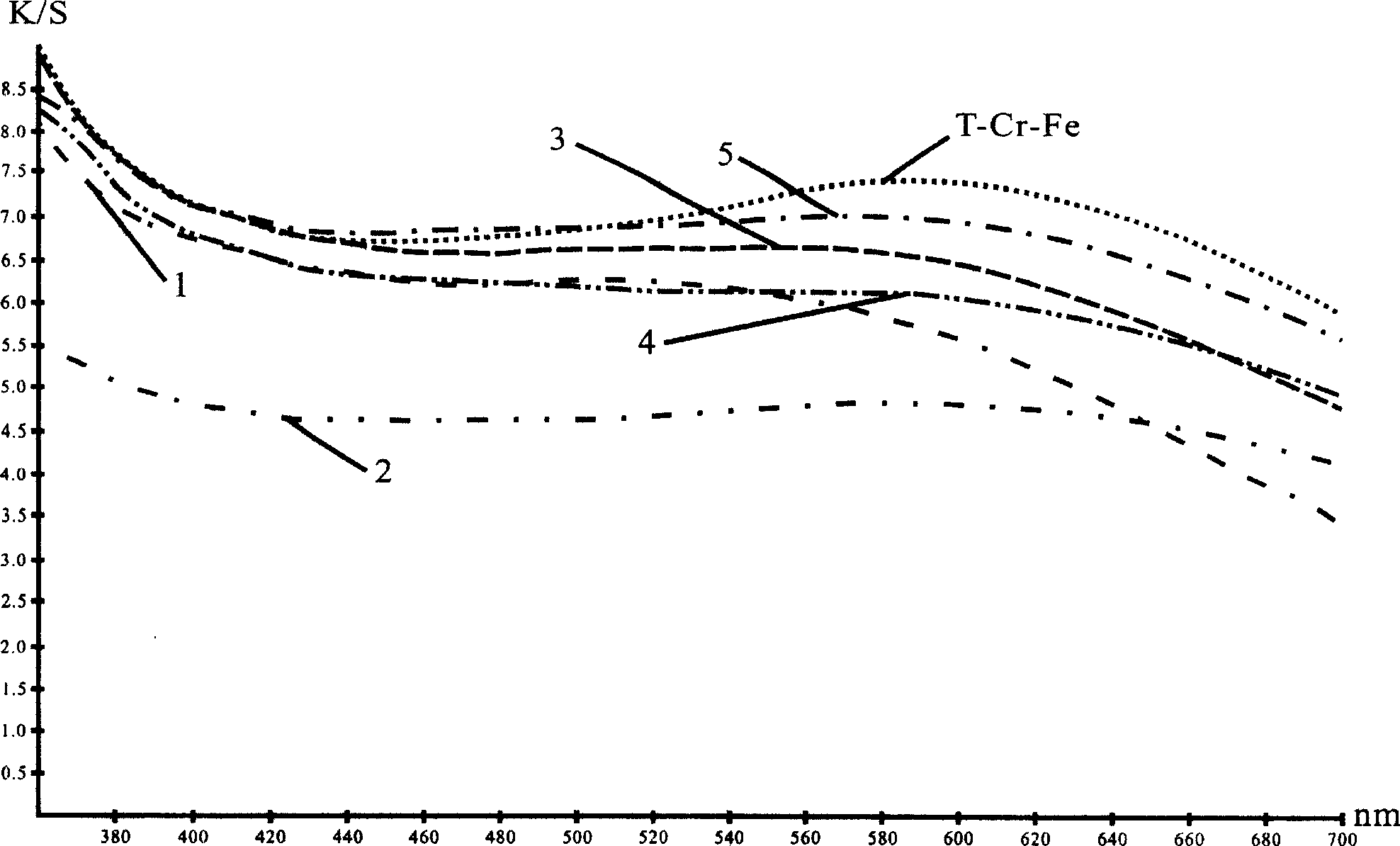

[0075] Example 3, the comparison of pure vegetable tanned leather, chromium-iron tanned leather and vegetable-chromium-iron combined tanned leather after artificial sweat washing, lye washing, soap washing, organic solvent washing and sun exposure.

[0076] 1. Chrome-iron tanning process:

[0077]Normal temperature water 100% (W / W), use formic acid to adjust pH3.0~3.5, add chromium-iron tanning agent, equivalent to 1.5% (W / W) of dichromium trioxide, and 0.7% of converted ferric oxide (W / W) , NaCl50g / L, turn for 180min, raise alkali 2-4 times, pH4.0, raise temperature 35-40°C, turn for 60min, stop the drum overnight, turn for 30min the next day, measure the shrinkage temperature, put on the horse, and let stand overnight. Washing, neutralization, fatliquoring and drying are carried out according to the conventional process. (150% of the weight of pickled leather is used as the calculation basis for tanning materials.)

[0078] 2. Pure vegetable tanning process:

[0079] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com