Vacuum opening/closing valve

A vacuum and vacuum pump technology, applied in the field of vacuum on/off valves, can solve the problems of corrugated seal damage, wear, large cracks, etc., and achieve the effect of preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

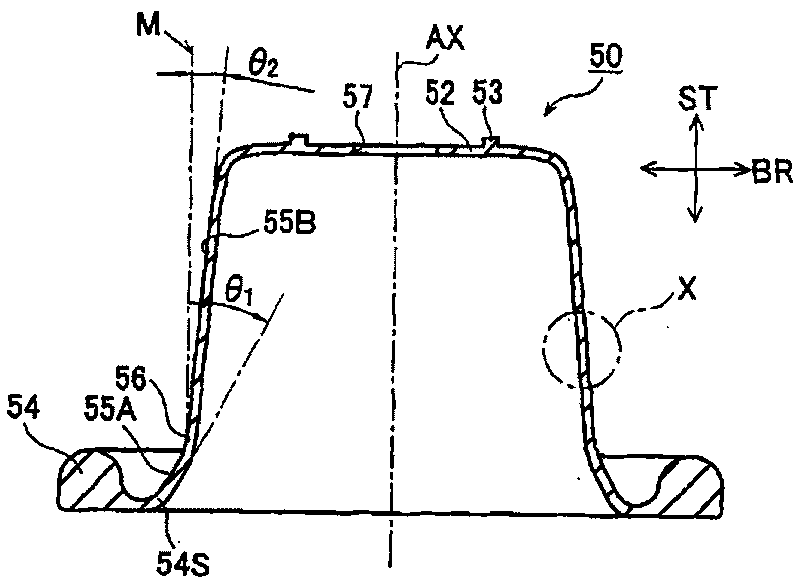

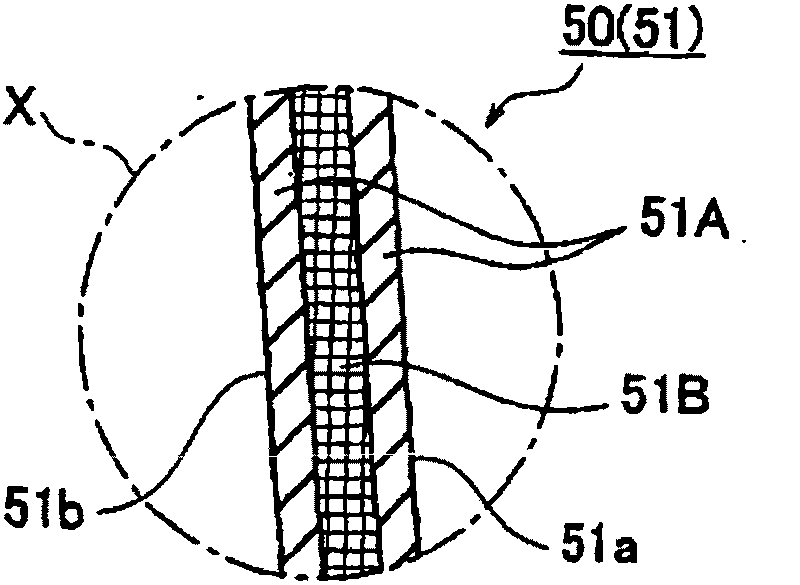

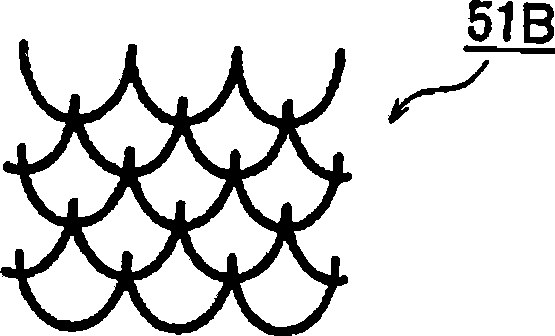

[0066] A detailed description will now be given of a preferred embodiment of a vacuum on / off valve embodying the present invention with reference to the accompanying drawings. Figure 10 is an explanatory diagram showing the configuration of the vacuum pressure control system 1 including the vacuum on / off valve 10 .

[0067] The vacuum pressure control system 1 is a system for performing surface treatment on a wafer 8 by alternately filling or exhausting a process gas and a purge gas into a vacuum chamber 2 in which the wafer 8 is placed in a semiconductor manufacturing process. Such as Figure 10 As shown in , the vacuum pressure control system 1 mainly includes a vacuum chamber 2 (vacuum container), a vacuum pump 5, an air supply source 6 for supplying driving air AR, a vacuum on / off valve 10, and a vacuum on / off valve 10 for controlling the vacuum. A feeding valve (not shown) with a certain opening degree, and a vacuum pressure controller 7 electrically connected to a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com