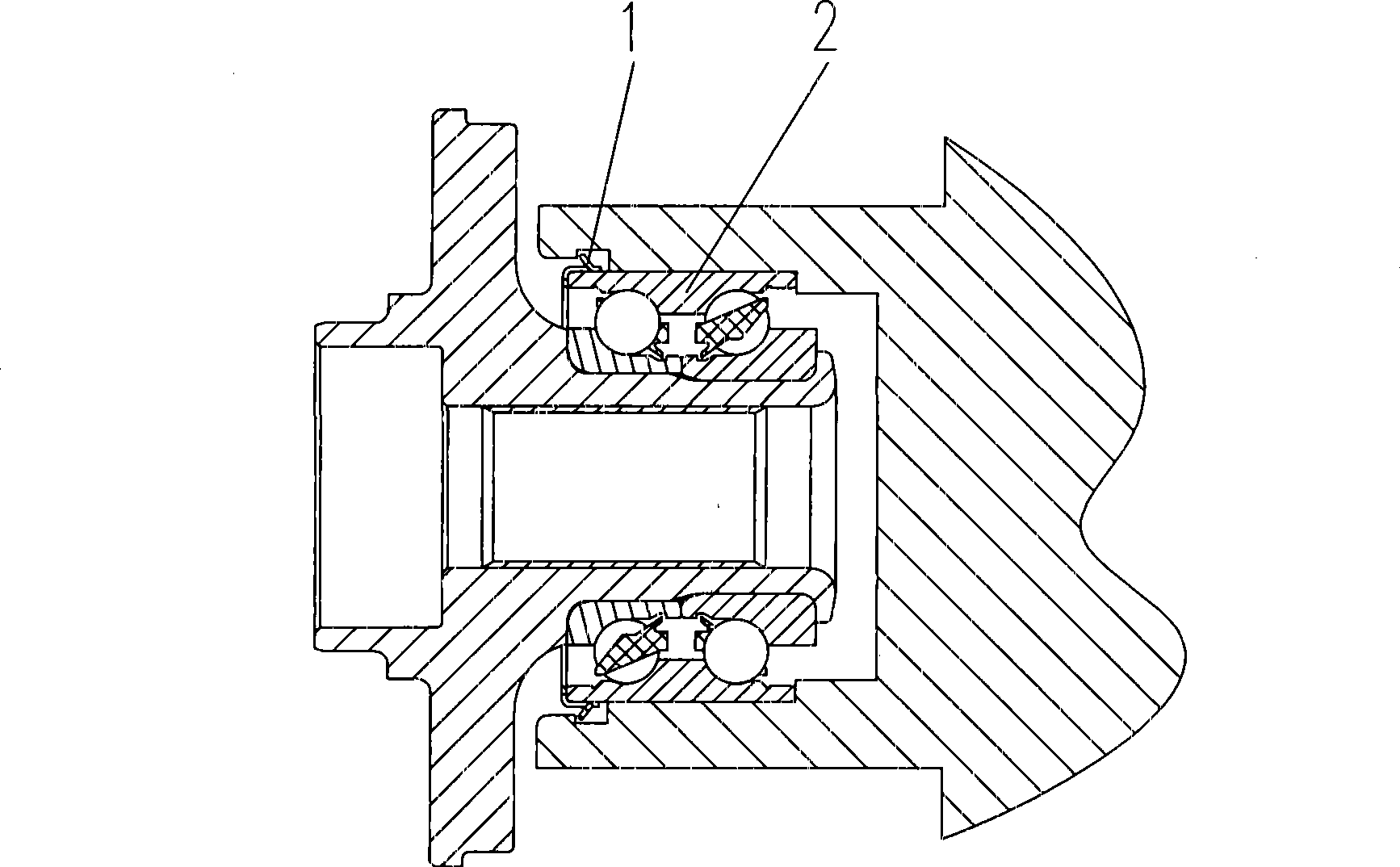

Automobile hub bearings limit ring manufacturing technique and production die thereof

A technology of automobile wheel hub and manufacturing process, which is applied in the field of auto parts production, can solve the problems of easy distortion and deformation of the workpiece, complex mold structure, long production cycle, etc., and achieve the effect of convenient operation, reasonable and simple process, and saving input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

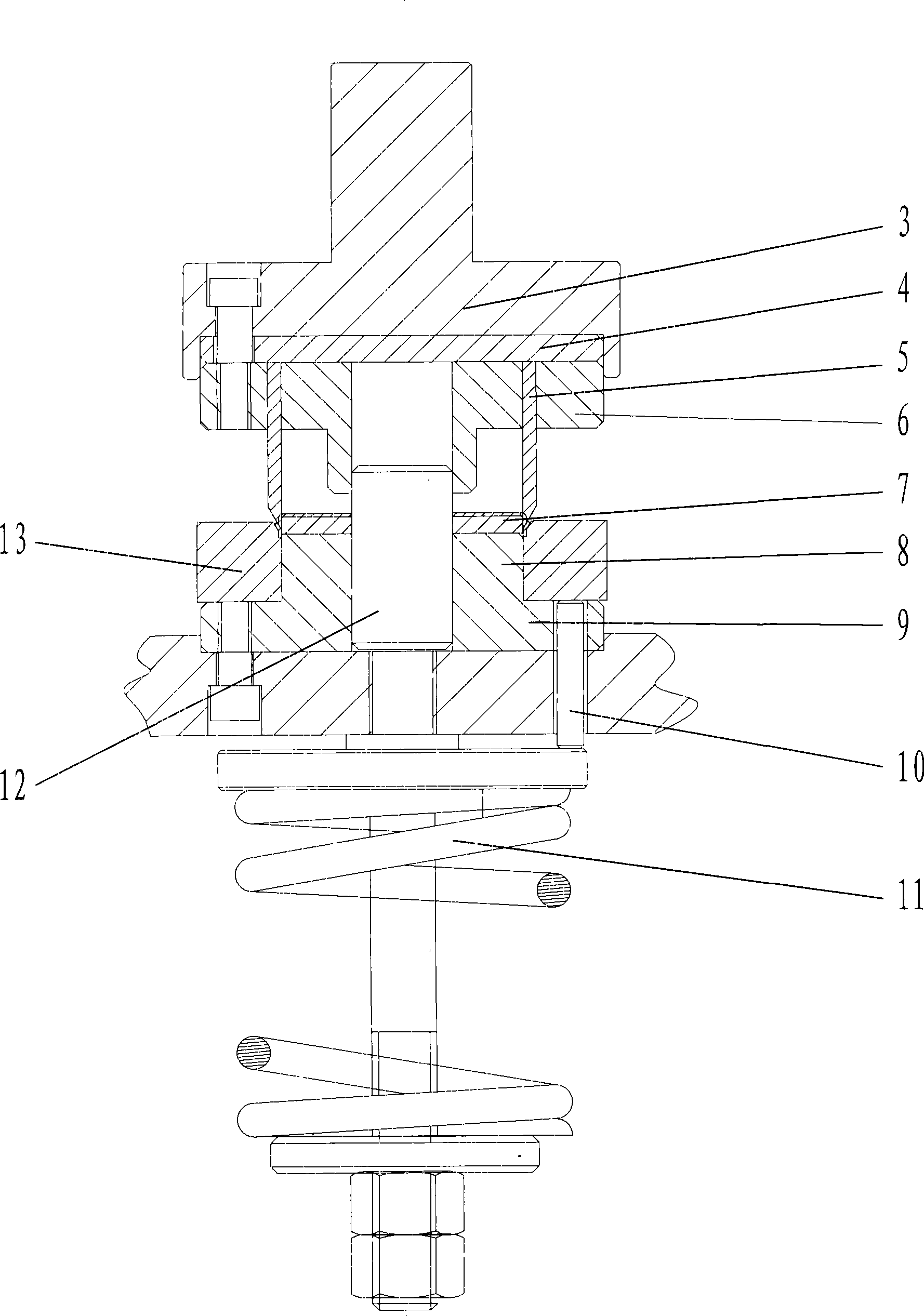

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

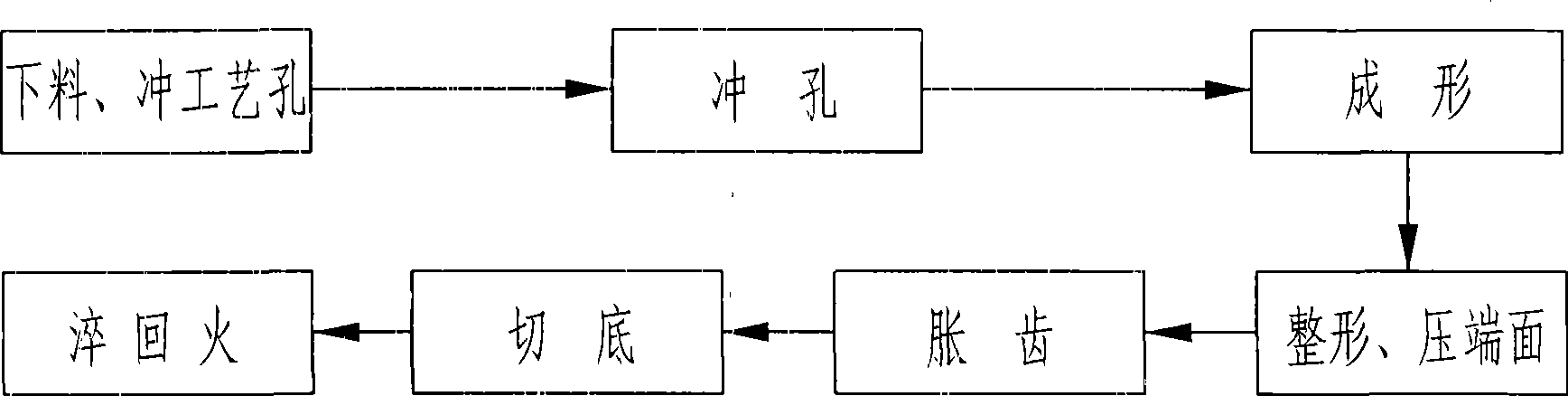

[0016] see figure 2 , a manufacturing process of a stop ring for an automobile hub bearing, including blanking, punching process holes, forming, shaping, pressing the end face, bottom cutting, quenching, and tempering. Between the shaping and pressing end face and the bottom cutting process, a tapered The tooth-shaped upper die is directly processed for tooth expansion, the material used for blanking is 65Mn, the workpiece is punched by 1mm spring steel plate, and then heat-treated and quenched after punching; the inner diameter matches the size IT9 grade precision, the largest outer diameter IT10 precision is higher than the limit deviation of the drawing diameter, and it is necessary to control the mold manufacturing precision and mold clearance; in addition, in terms of height, If the limit deviation of the height of the drawn part is exceeded,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com