TIG welding gun and welding cooling method

A welding torch and cooling pipe technology, applied in the field of welding equipment, can solve the problems of high sealing performance and sealing material requirements, affecting welding quality welding torch service life, easy leakage of cooling water, etc., so as to improve the welding torch service life and be beneficial to the protection of the welding seam. , to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

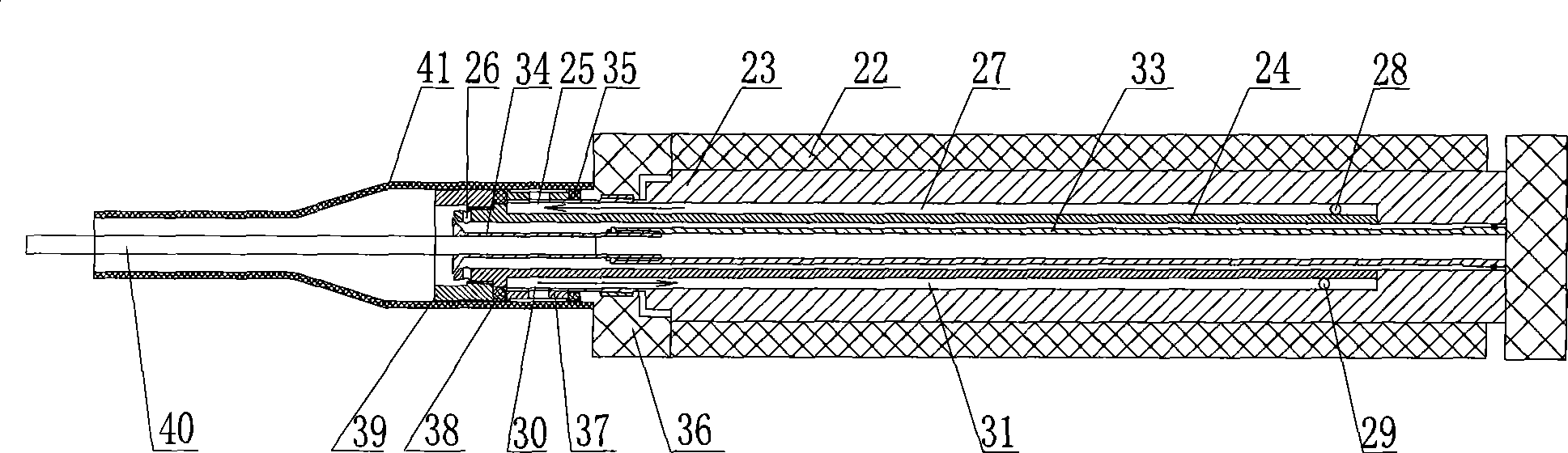

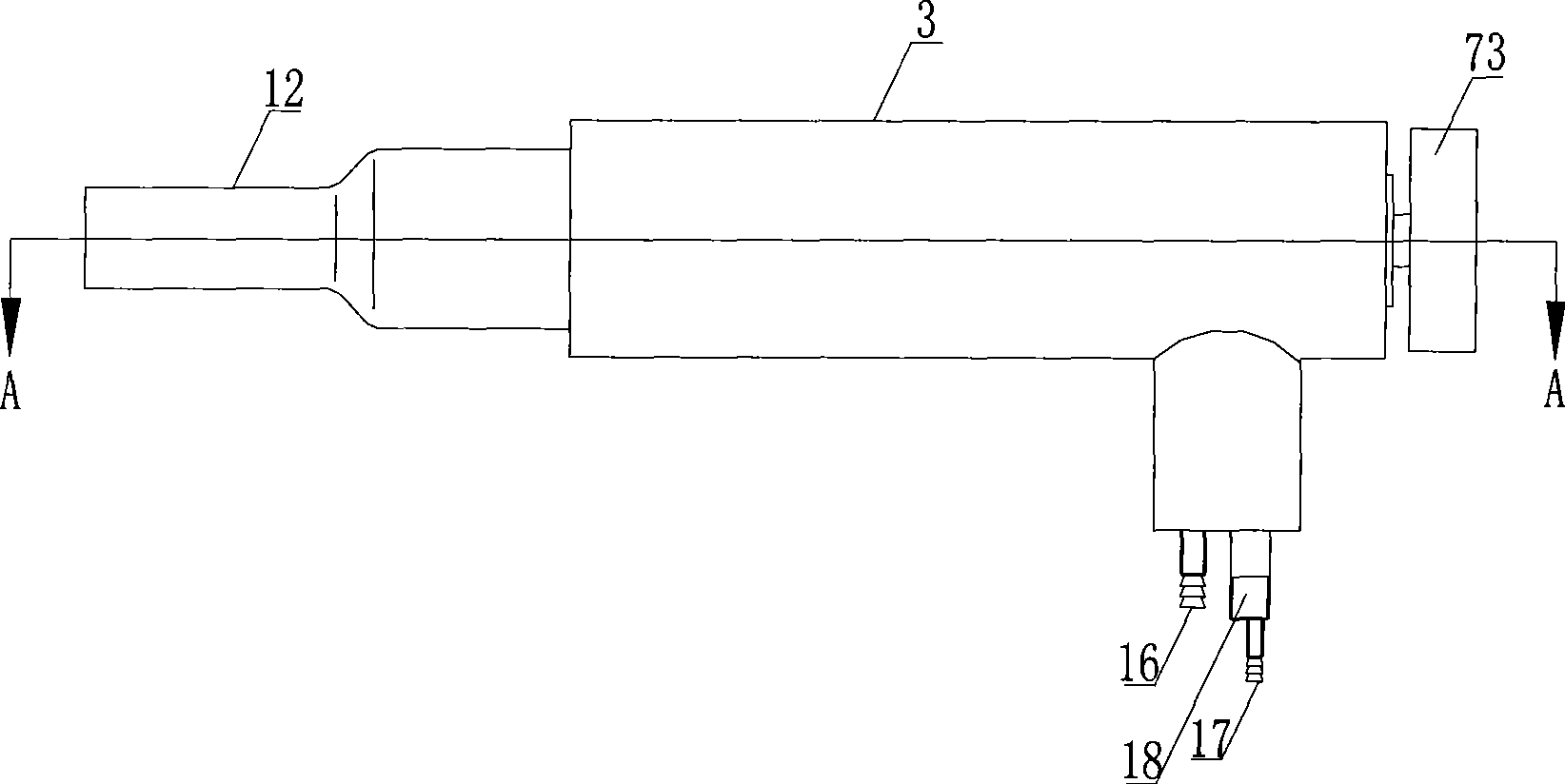

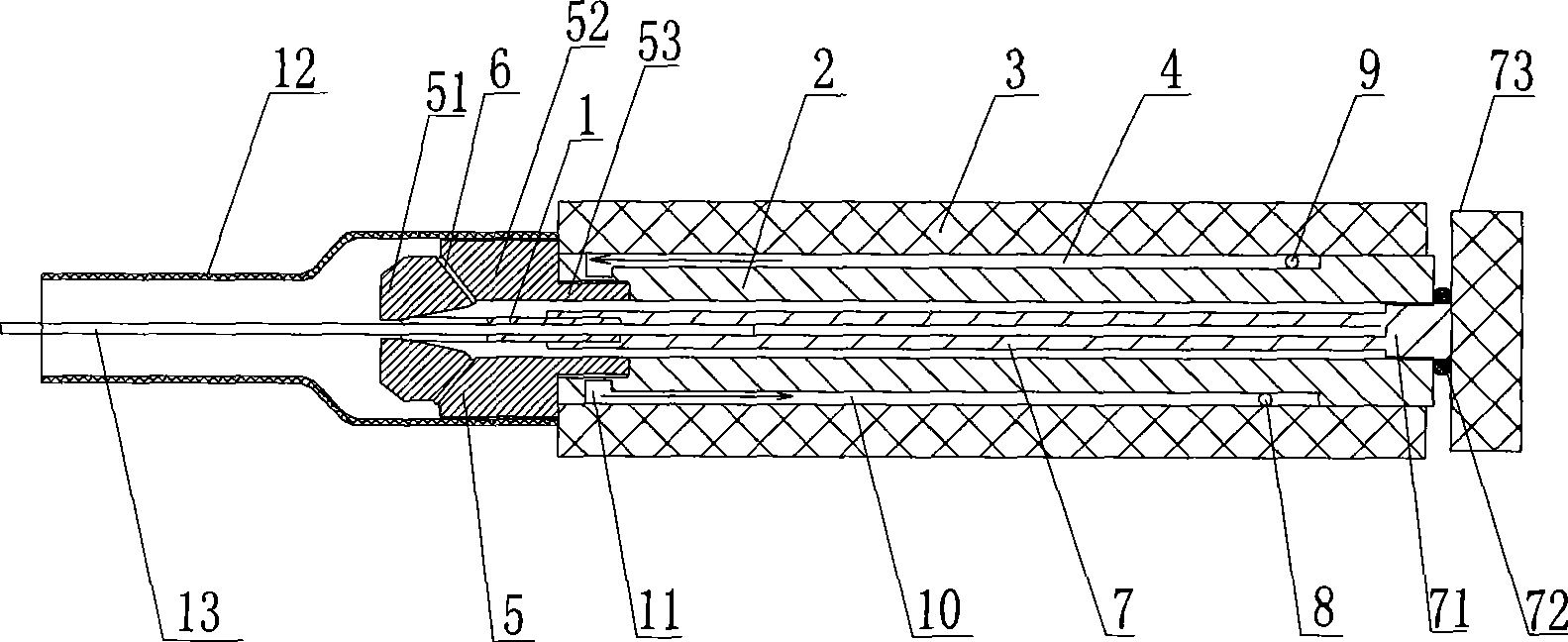

[0023] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments. in, figure 2 It is a schematic diagram of the appearance structure of the TIG welding torch of the present invention; image 3 for figure 2 Structural sectional view along the A-A direction.

[0024] In this specification, the end relatively close to the torch head is the front end, and the end relatively far away from the torch head is the rear end or end.

[0025] Such as figure 2 and image 3 As shown, in the TIG welding torch of the preferred embodiment of the present invention, the torch head includes a tungsten pole 13, a shielding gas cover 12 and a fixing seat 5; the torch body includes an insulating bush 3 coaxially sleeved from outside to inside, and a cooling tube Body 2, tungsten clamp 1 and compression adjustment rod 7, the fixed seat 5 includes a cylindrical fixed seat body 52, a front end portion 51 and a connecting portio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com