Liquid sulfur trioxide and method for producing high concentration fuming sulfuric acid

A liquid sulfur trioxide and fuming sulfuric acid technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of inconvenient product quality control, achieve uniform temperature difference, reduce production costs, and improve evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

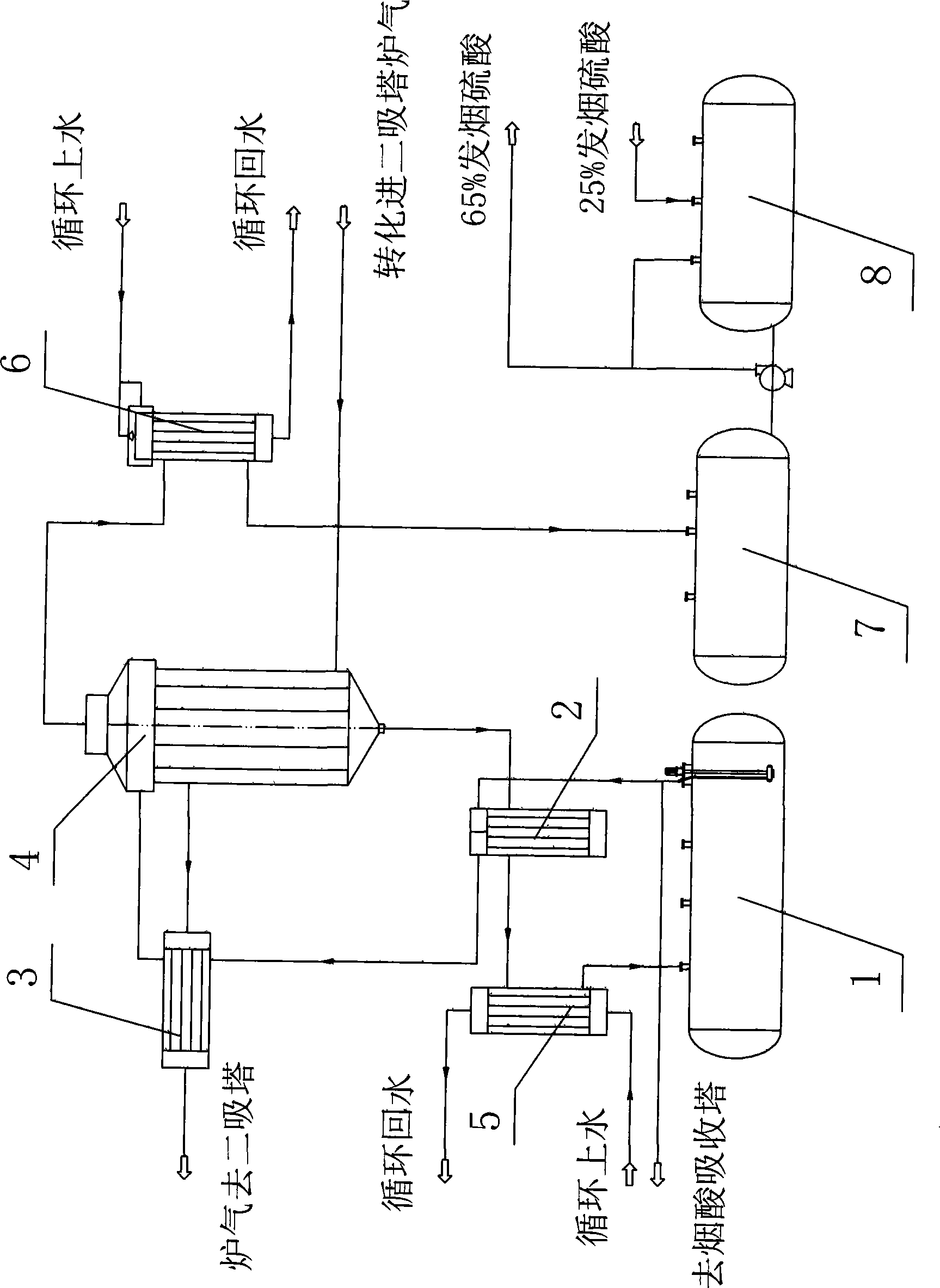

[0017] The first step, as the raw material acid, sends 25% to 30% oleum in the sulfuric acid production system into the oleum preheater 2 through the circulation tank 1, and desorbs the SO outflow from the sulfur trioxide evaporator. 3 Heat exchange with 12% fuming sulfuric acid (back to acid) with a residual temperature of 106°C after the gas, preheat 25% to 30% fuming sulfuric acid to 100°C, then enter heater 3, and heat from sulfur trioxide evaporator 4 After the fuming sulfuric acid, the reformer gas whose temperature drops to 170°C-180°C is further heat-exchanged, and the temperature of 25%-30% fuming sulfuric acid is raised to 120°C and then sent to the sulfur trioxide evaporator 4, where the sulfur trioxide evaporator 4 is heated by the reformer gas from the sulfuric acid system, and the SO in 25% to 30% oleum is 3 Desorb it out to get 100% sulfur trioxide gas.

[0018] The second step is to send the reformer gas from the reforming system to the sulfur trioxide evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com