Compound material constructed by molecular engram and fluorescent conjugated polymer, preparation and application

A technology of conjugated polymers and molecular imprinting, which is applied in the fields of material inspection products, fluorescence/phosphorescence, material excitation analysis, etc., and can solve the problems of slow response, unsuitable for on-site detection, rapid, sensitive and high selectivity detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

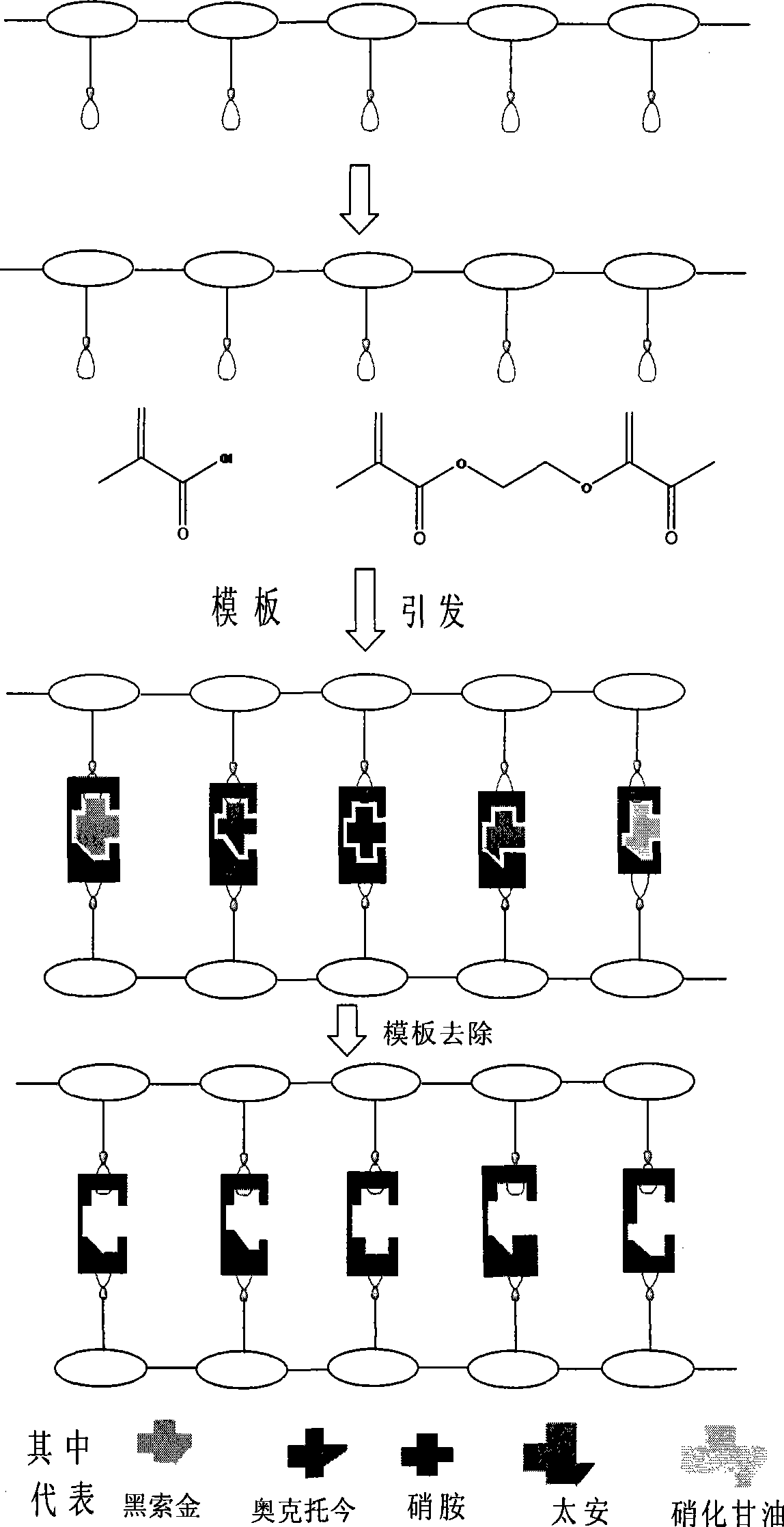

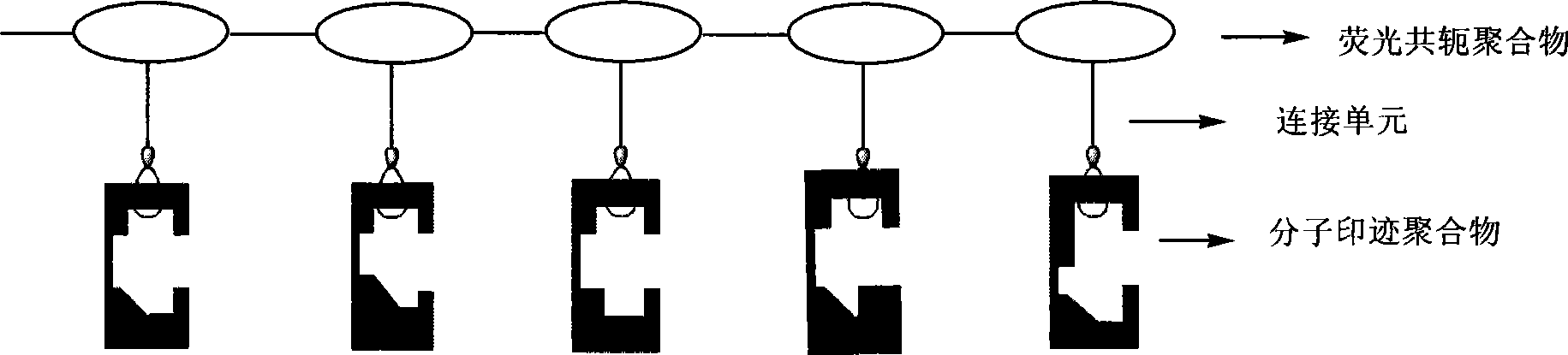

[0033] Embodiment 1 Synthesis process is as follows:

[0034] Side chain (12 carbons) TNT-sensitive fluorescent conjugated polymer containing molecularly imprinted active monomer 1mmol (see structure Figure 4 ), acrylamide (1mmol), di(methacrylic acid)-ethylene glycol ester (4mmol), explosive template molecules (including Octogen, RDX, nitroglycerin, the ratio of the three is 1:1:1 , a total of 0.018mmol), add 0.012mmol of benzoyl peroxide, dissolve in 5mL of toluene, and heat to 60-70°C to react for 6 hours. The resulting polymer was precipitated, centrifuged, and the polymer was washed successively with toluene and ethanol. Soxhlet extractor extracts and removes template molecules to obtain a light yellow composite polymer with a yield of 85%.

Embodiment 2

[0035] Embodiment 2 (change crosslinking monomer), synthetic process is as follows:

[0036] 1 mmol of TNT-sensitive fluorescent conjugated polymers with double side chains (12 carbons) containing molecularly imprinted active monomers (see Figure 4 ), acrylic acid (1mmol), di(methacrylic acid)-ethylene glycol ester (4mmol), explosive template molecules (including Octogen, RDX, nitroglycerin, the ratio of the three is 1:1:1, 0.018mmol in total), add 0.012mmol of benzoyl peroxide, dissolve in 5mL of toluene, and heat to 60-70°C to react for 6 hours. The resulting polymer was precipitated, centrifuged, and the polymer was washed successively with toluene and ethanol. Soxhlet extractor extracts and removes template molecules to obtain a light yellow composite polymer with a yield of 87%.

Embodiment 3

[0037] Embodiment 3 (carbon chain length changes)

[0038] 1 mmol of TNT-sensitive fluorescent conjugated polymers with double side chains (6 carbons) containing molecularly imprinted active monomers (see Figure 4 ), acrylamide (1mmol), di(methacrylic acid)-ethylene glycol ester (4mmol), explosive template molecules (including Octogen, RDX, nitroglycerin, the ratio of the three is 1:1:1 , a total of 0.018mmol), add 0.012mmol of benzoyl peroxide, dissolve in 5mL of toluene, and heat to 60-70°C to react for 6 hours. The resulting polymer was precipitated, centrifuged, and the polymer was washed successively with toluene and ethanol. Soxhlet extractor extracts and removes template molecules to obtain a light yellow composite polymer with a yield of 90%. The product is less soluble in common solvents such as DMF and DMSO. Not suitable for further device preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com