Method for preparing rare-earth aluminum silicon alloy by waste aluminum recovery and rare-earth aluminum silicon alloy thereof

A rare-earth alloy and rare-earth aluminum technology, applied in the field of aluminum-silicon alloy, can solve problems such as unstable metallurgical quality in production, high energy consumption in waste aluminum recycling process, imperfect component detection and quality control methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

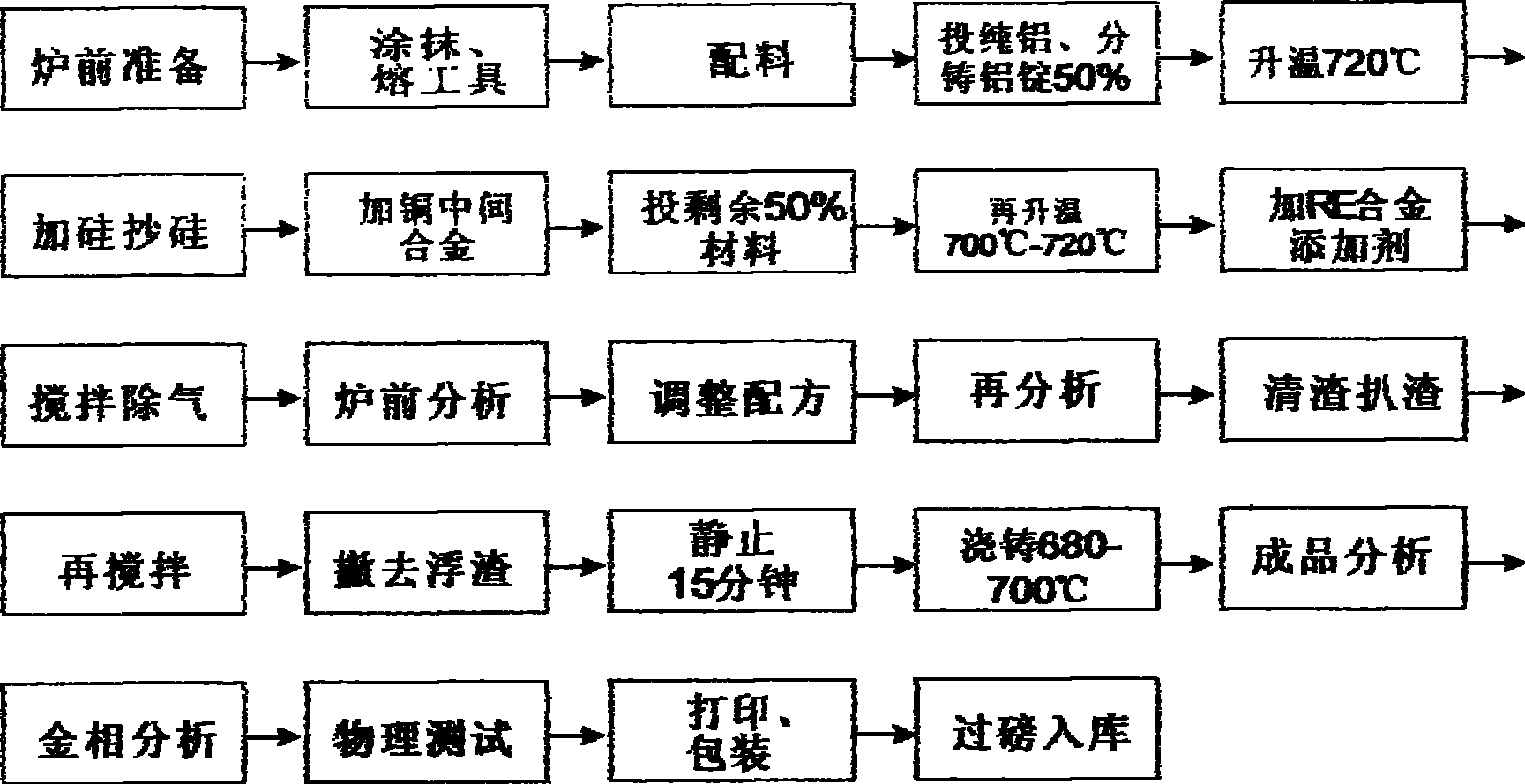

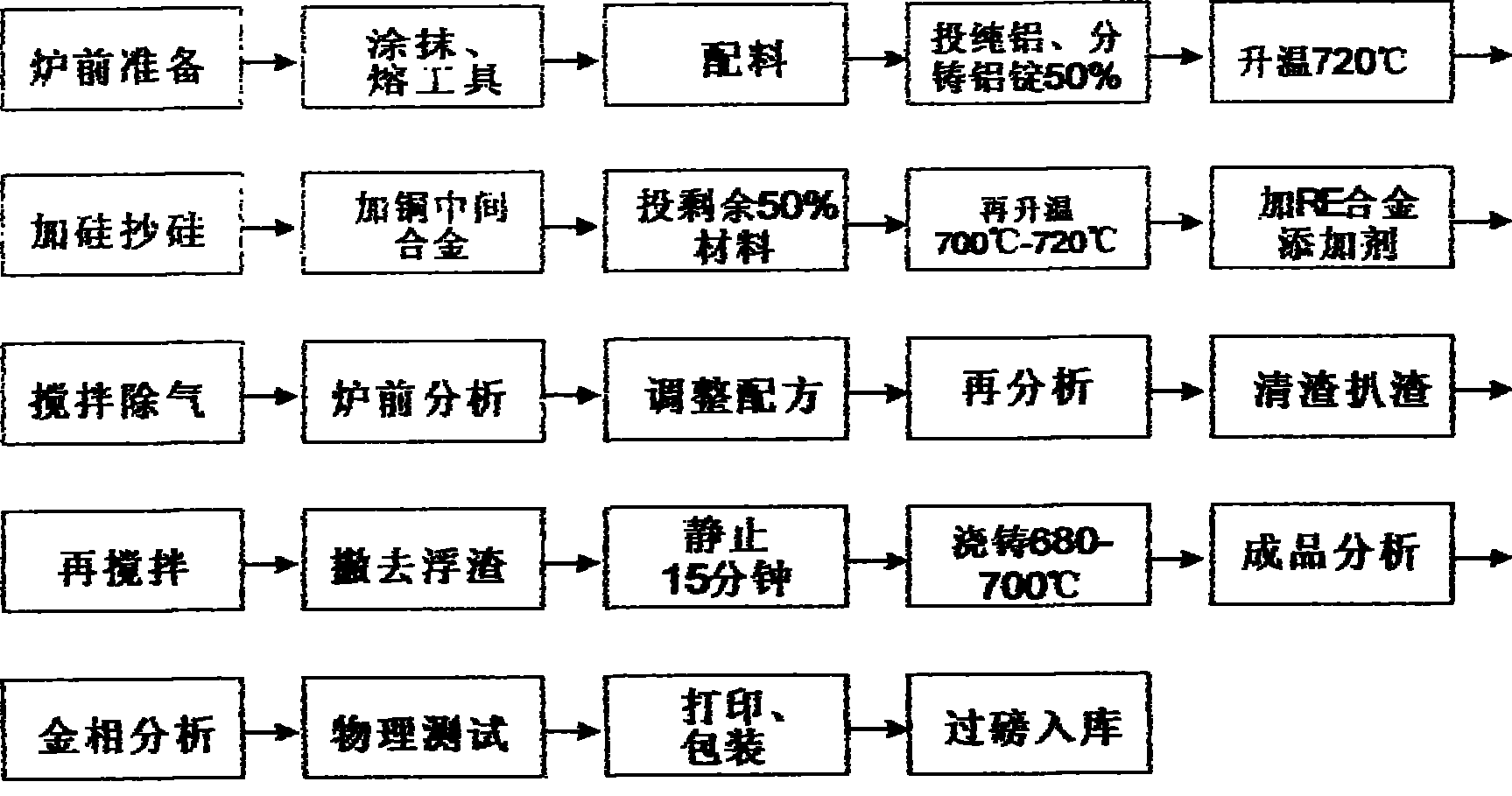

[0026] Such as figure 1 Shown, the production technology of aluminum-silicon alloy of the present invention comprises:

[0027] 1. Pretreatment of waste aluminum: After the waste materials are sorted and stacked ~ manual sorting and sorting ~ careful magnetic separation ~ preliminary detection and analysis and other processes, they are ready for use.

[0028] Specifically, the process is determined according to the size and shape of the waste as follows: A. Large pieces and slices, classified according to components → remove other metals and inserts → bake to remove oil and paint; B. Powder and waste and scrap, classification → Drying to remove water → magnetic separation, winnowing, parabolic separation → roasting; C. cans, etc., chopping → roasting to remove paint → briquetting.

[0029] The purpose of pretreatment is to classify waste aluminum according to the alloy composition, remove water, oily paint, and other metal impurities, strictly control water during pretreatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com