Fibrillation dissolving pulp, method for making same and applications

A technology of fibrillation and pulp, which is applied in the field of fibrillation pulp and its preparation, can solve the problems of difficult simultaneous control of pulp length and fibrillation degree, fibrils, main fiber entanglement, and difficulty in dispersing, etc., to achieve The process has a wide range of use, great flexibility, and the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

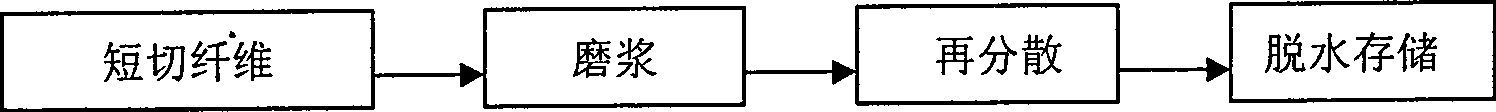

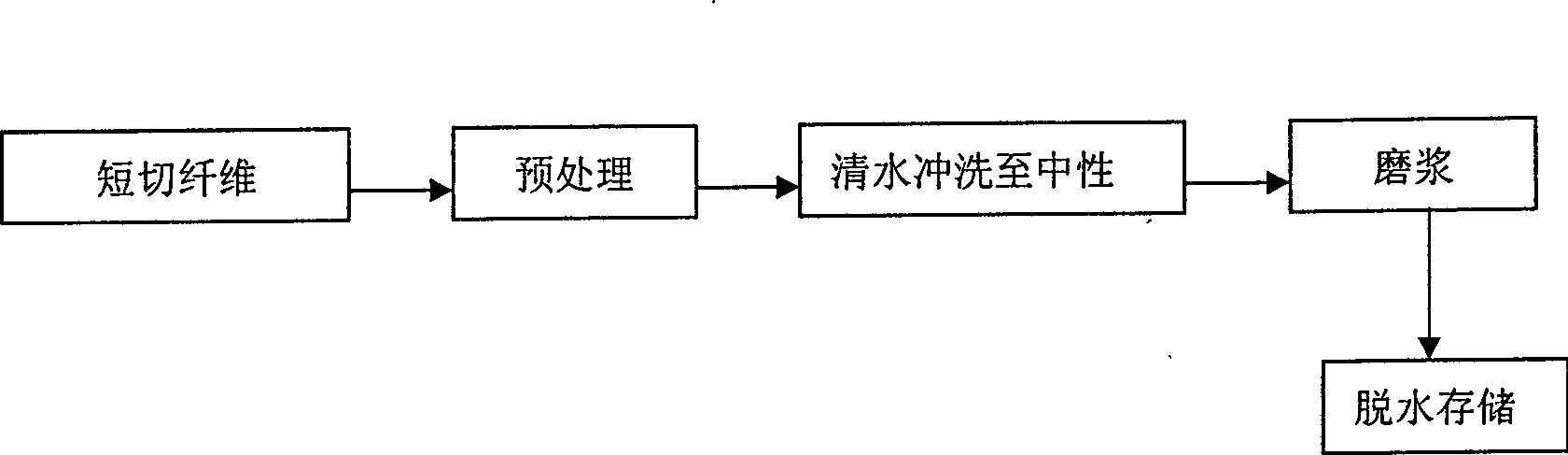

[0040] 15g para-aramid chopped fiber ( 2-4 mm in length, 15 μm in diameter), soaked in 70% sulfuric acid for 8 minutes, and the soaking concentration is 0.1% w.t. After soaking, take out the fibers and rinse them with clean water until neutral. PFI is used for refining, the refining concentration is 10%, the refining distance is 2mm, and the number of refining revolutions is 10,000 rpm to prepare pulp. The process is shown in figure 2 , the properties of pulp are shown in Table 2.

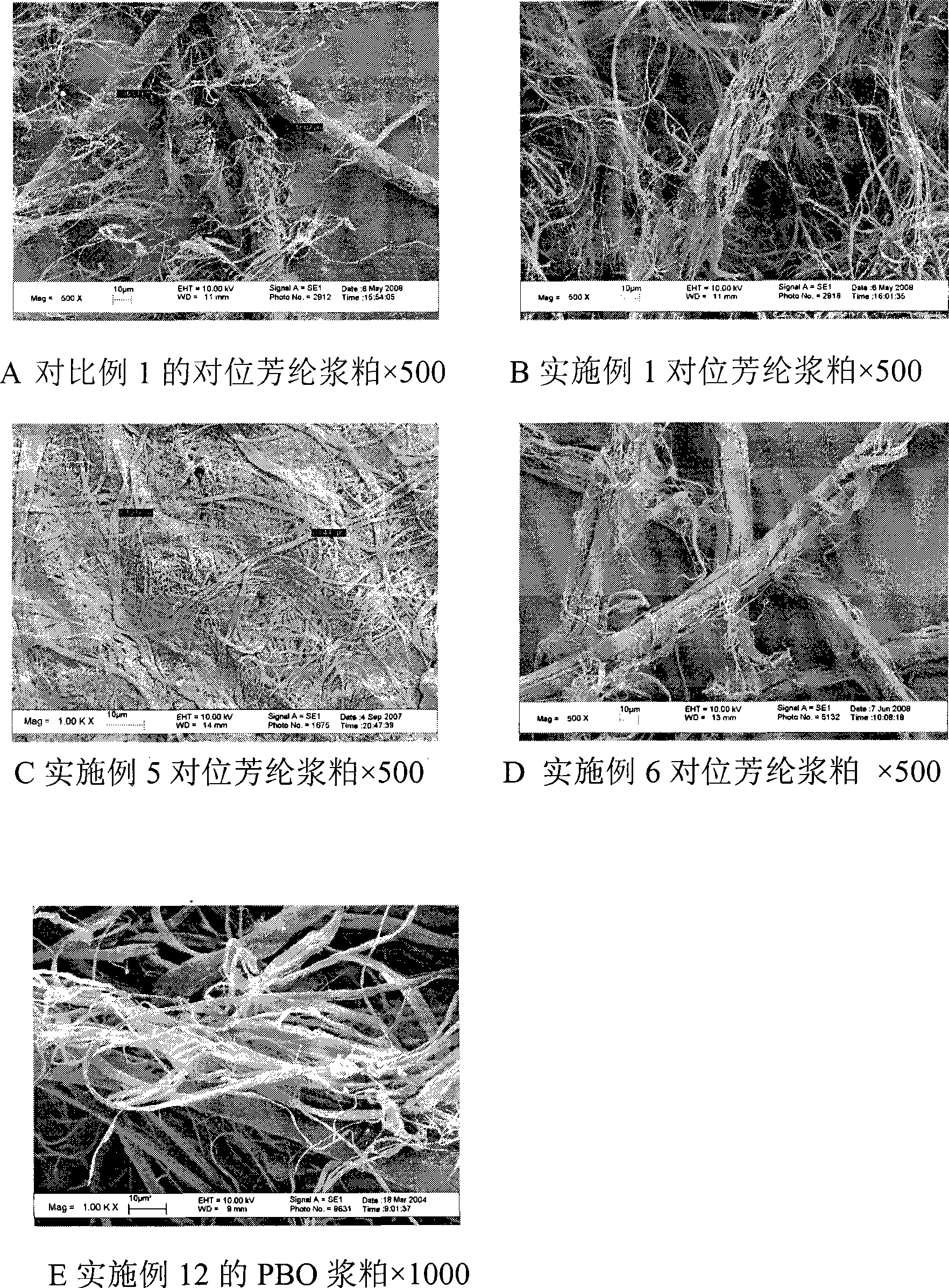

[0041] The water retention value of the pulp of this embodiment is 104.2%, which is 8.2 percentage points higher than that of the pulp of Comparative Example 1. From the side, the degree of fibrillation of the pulp of this embodiment is higher than that of the pulp of Comparative Example 1. Pretreatment Play a more ideal effect. This embodiment pulp sees image 3 B, contrast with comparative example 1 pulp (see image 3 A), the degree of fibrillation of the pulp in this example is much higher,...

Embodiment 2

[0043] The pulp preparation process of this embodiment is the same as that of Example 1, the difference is that the concentration of sulfuric acid used for pretreatment is 10%. For the process, see figure 2 , the properties of pulp are shown in Table 2.

Embodiment 3

[0045] The pulp preparation process of this embodiment is the same as that of Example 1, the difference is that the concentration of pretreatment sulfuric acid used is 60%, and the process is shown in figure 2 , the properties of pulp are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com