Glass fibre reinforced plastic sand inclusion well chamber

A fiberglass-reinforced sand-inclusion and well chamber technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as waterproofing, confluence and diversion effects are not very ideal, consume a lot of manpower and material resources, and the work process is cumbersome, etc., to achieve Excellent waterproof and anti-seepage performance, short construction period and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

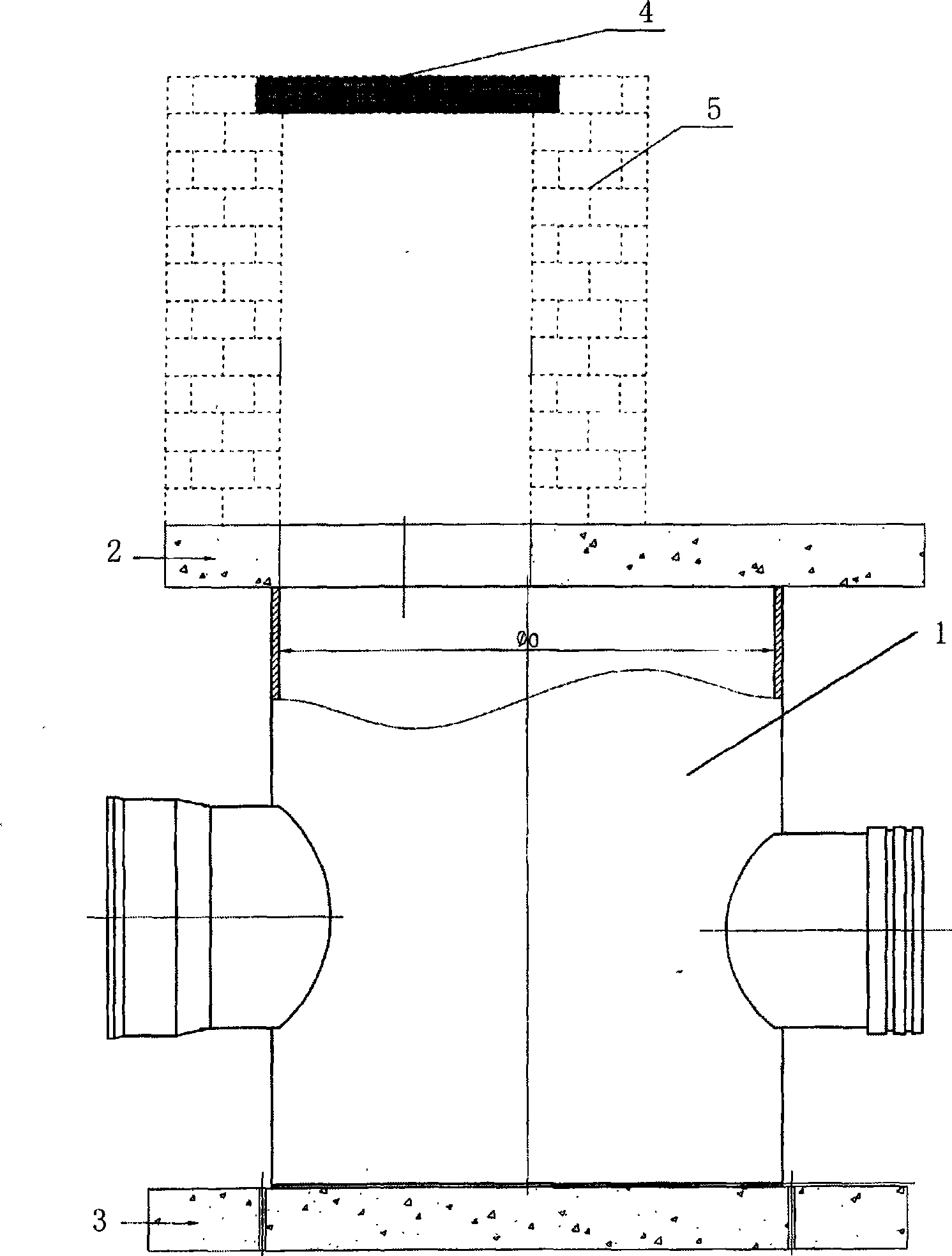

[0024] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the present invention.

[0025] The FRP sand-filled well chamber of the present invention is made of glass fiber winding reinforced thermosetting resin, that is, unsaturated polyester resin, and quartz sand; wherein the glass fiber is wound clockwise and counterclockwise unsaturated polyester resin It is made of multiple layers, and other crafts are made by traditional crafts.

[0026] The main body 1 of the well chamber according to the present invention is a cylindrical structure, and the well wall and the well bottom are integrated. A precast concrete cover plate 2 is also provided on the upper part of the main body 1 of the well chamber, and a precast concrete bottom plate 3 is provided on the lower part of the main body 1 of the well chamber.

[0027] The main body 1 of the well chamber is also provided with a plurality of water distribution pipe interfaces, and may be provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com