Method for implementing open-channel flow measurement by mechanical structure

A technology of flow measurement and mechanical structure, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as measurement failure, insufficient power supply continuity, and susceptibility to external noise interference, etc., to achieve Effects that are not disturbed by noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

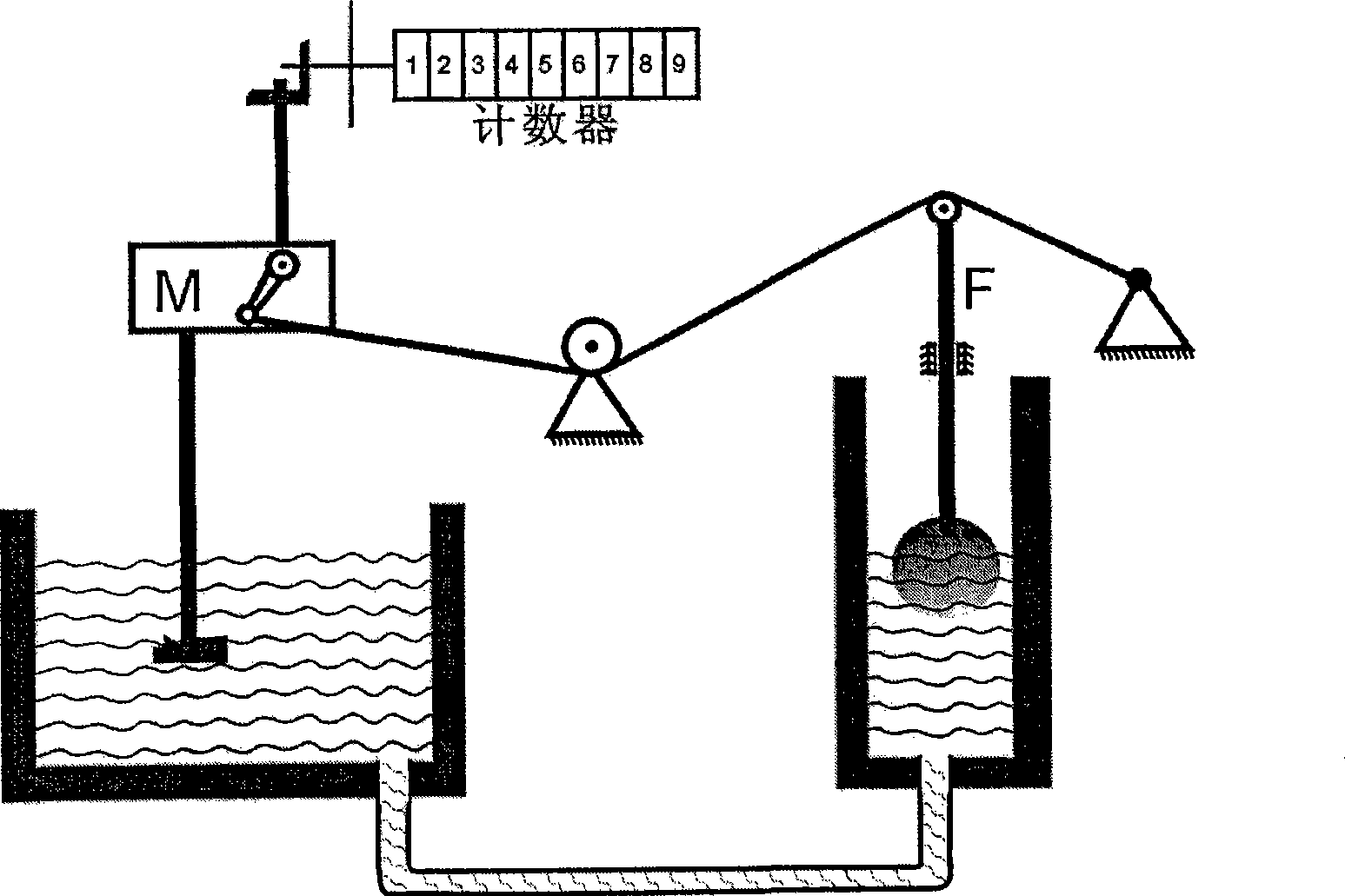

[0027] 1, the technical basis of the present invention is:

[0028] Let the cross-sectional area of the channel be S, S is a function of water level h, h is a function of time t, then S=S(h), h=h(t), that is: S=S(h(t))

[0029] Q T = ∫ 0 T S ( h ( t ) ) V ( t ) dt - - - ( 1 )

[0030] Where V(t) is the average water velocity of the section.

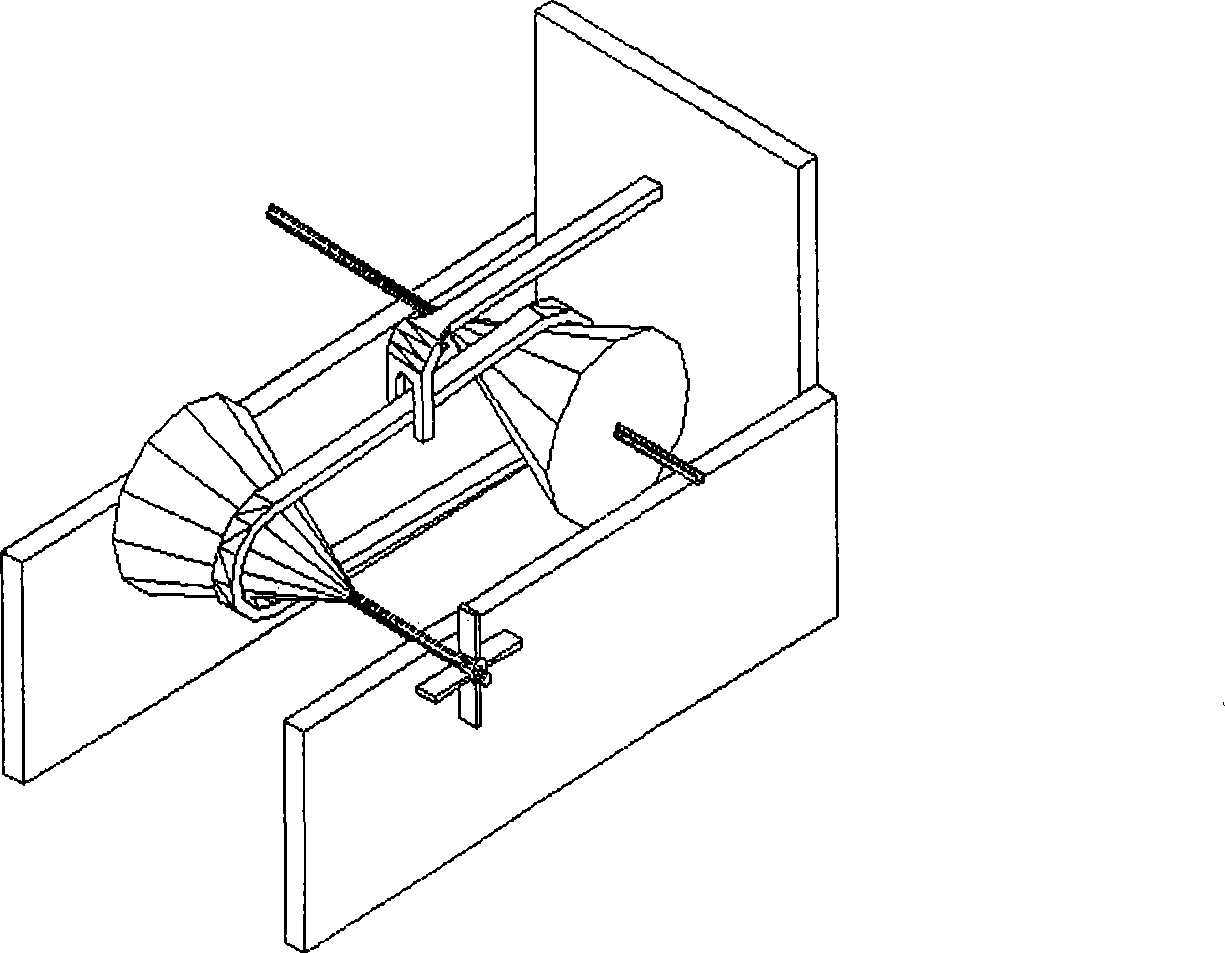

[0031] Insert an impeller at this section, half of which is blocked by the casing, so that rotation will occur under the impact of the water flow, satisfying: V(t)=Rω(t), where R is the hydraulic radius of the wheel blade, and ω(t) is The rotational angular velocity of the impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com