Method for detecting cementing quality between tin babbit alloy and lined steel

A technology of tin-based bearing alloy and bonding quality, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of high work intensity, cumbersome operation, and low detection efficiency, so as to improve detection speed, facilitate instrument adjustment, The effect of high defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Next, a detection and analysis will be performed on the bonding state between the tin-based bearing alloy on the upper slider of the marine diesel engine and the lining steel, and the method of the present invention will be used specifically.

[0039] In practical application, the ultrasonic flaw detector of the present invention is the CTS-2000 type, the frequency of the probe is 2.5MHz, and the diameter of the chip inside the probe is Φ20mm.

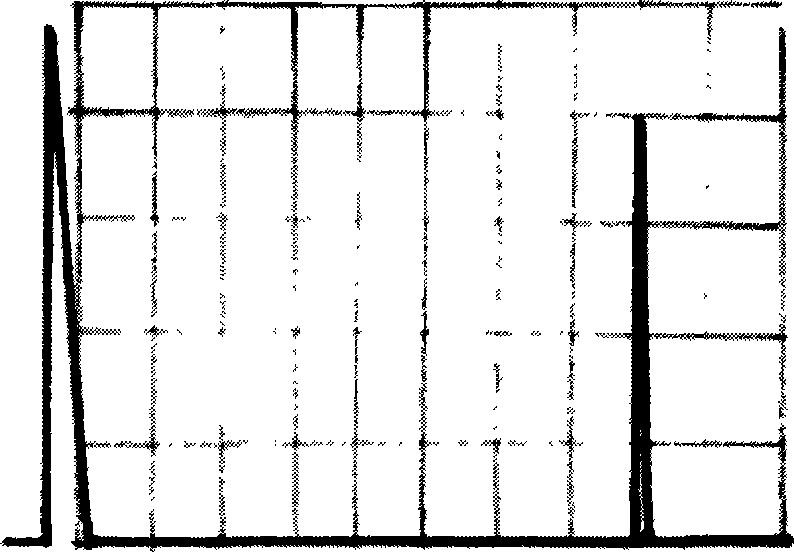

[0040] Adjustment of the ultrasonic detector: Place the probe connected to the instrument on the tin-based bearing alloy surface of the slider with good composite bonding quality. Such as Figure 4 as shown, Figure 4 It is a schematic diagram of the detection state in Example 1 in a method for detecting the bonding quality of tin-based bearing alloy and lining steel of the present invention. The two sides of the slide block of the marine diesel engine in the figure are made of composite metal, and the probe of the detector ne...

Embodiment 2

[0043]Next, a detection and analysis will be performed on the bonding state between the tin-based bearing alloy on the upper thrust block of the marine diesel engine and the lining steel, and the method of the present invention will be used specifically.

[0044] In practical application, the ultrasonic flaw detector of the present invention is the CTS-2000 type, the frequency of the probe is 2.5MHz, and the diameter of the chip inside the probe is Φ20mm.

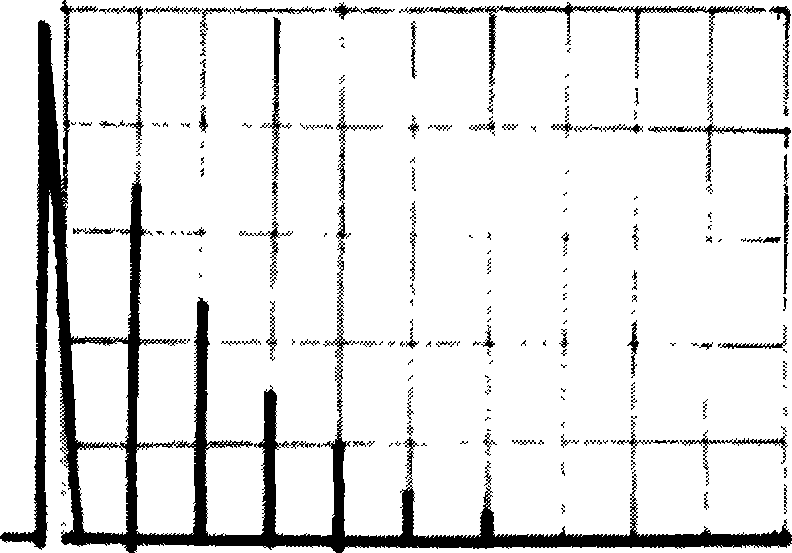

[0045] Adjustment of the ultrasonic detector: Place the probe connected to the instrument on the tin-based bearing alloy surface of the thrust block with good composite bonding quality, such as Figure 5 as shown, Figure 5 It is a schematic diagram of the detection state in Example 2 in a method for detecting the bonding quality of the tin-based bearing alloy and the lining steel of the present invention. One side of the thrust block of the marine diesel engine in the picture is made of composite metal. It is necessary to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com