Auto testing system for electronic transformer

An automatic test system, electronic transformer technology, applied in the direction of measuring electrical variables, instruments, measuring electricity, etc., can solve the problems of large manpower demand, low efficiency, low work efficiency, etc., to improve test efficiency, test results Accurate, Test the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

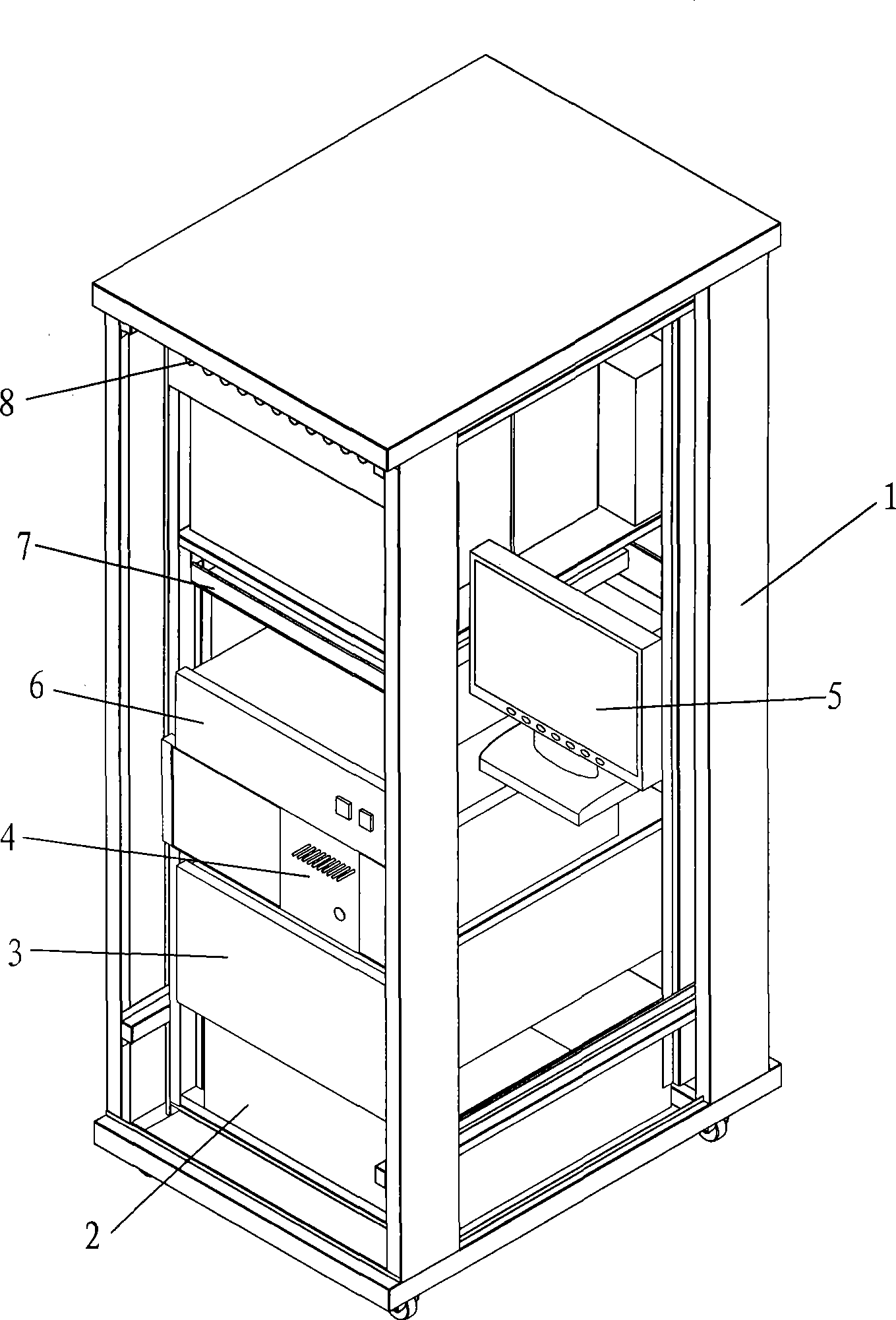

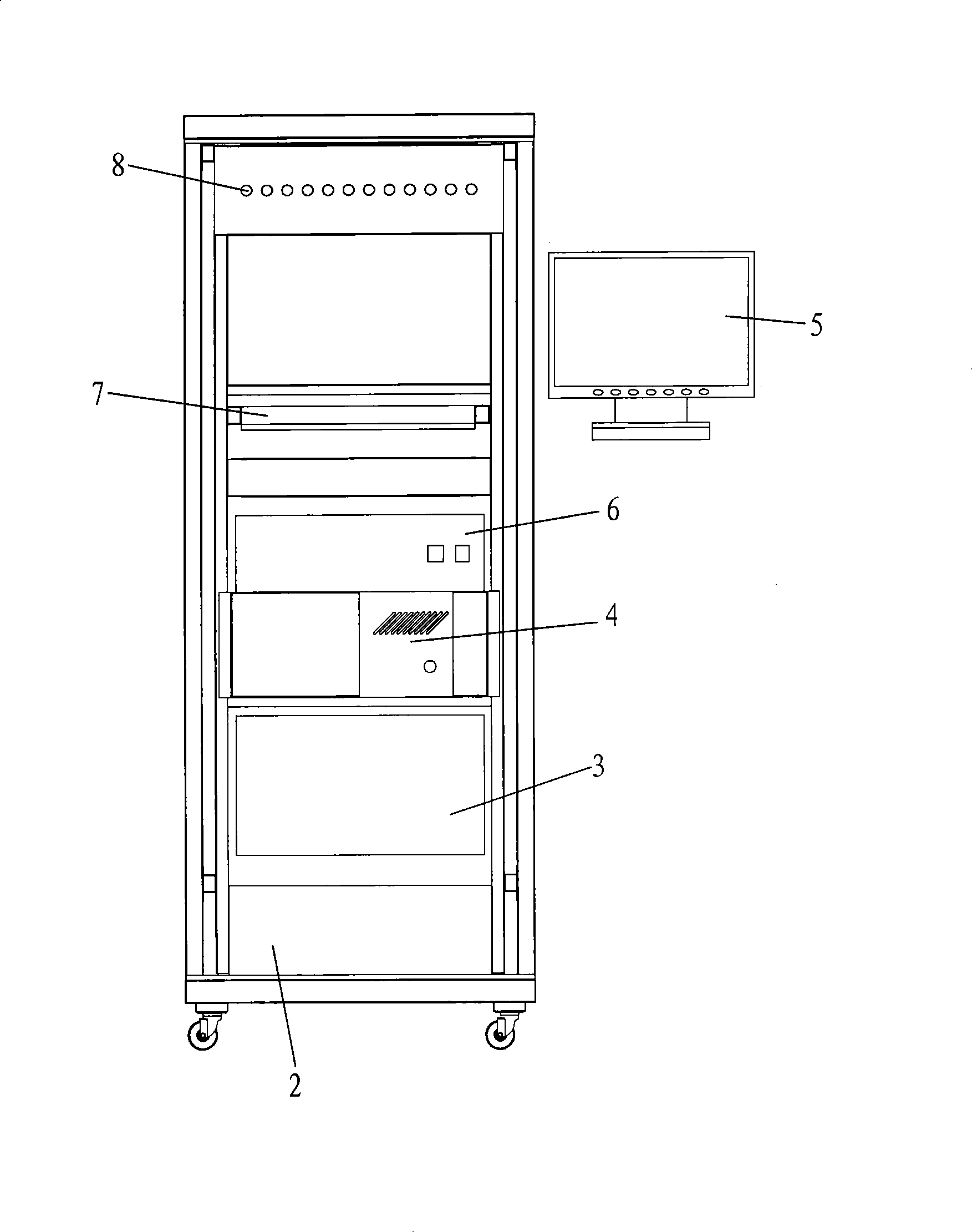

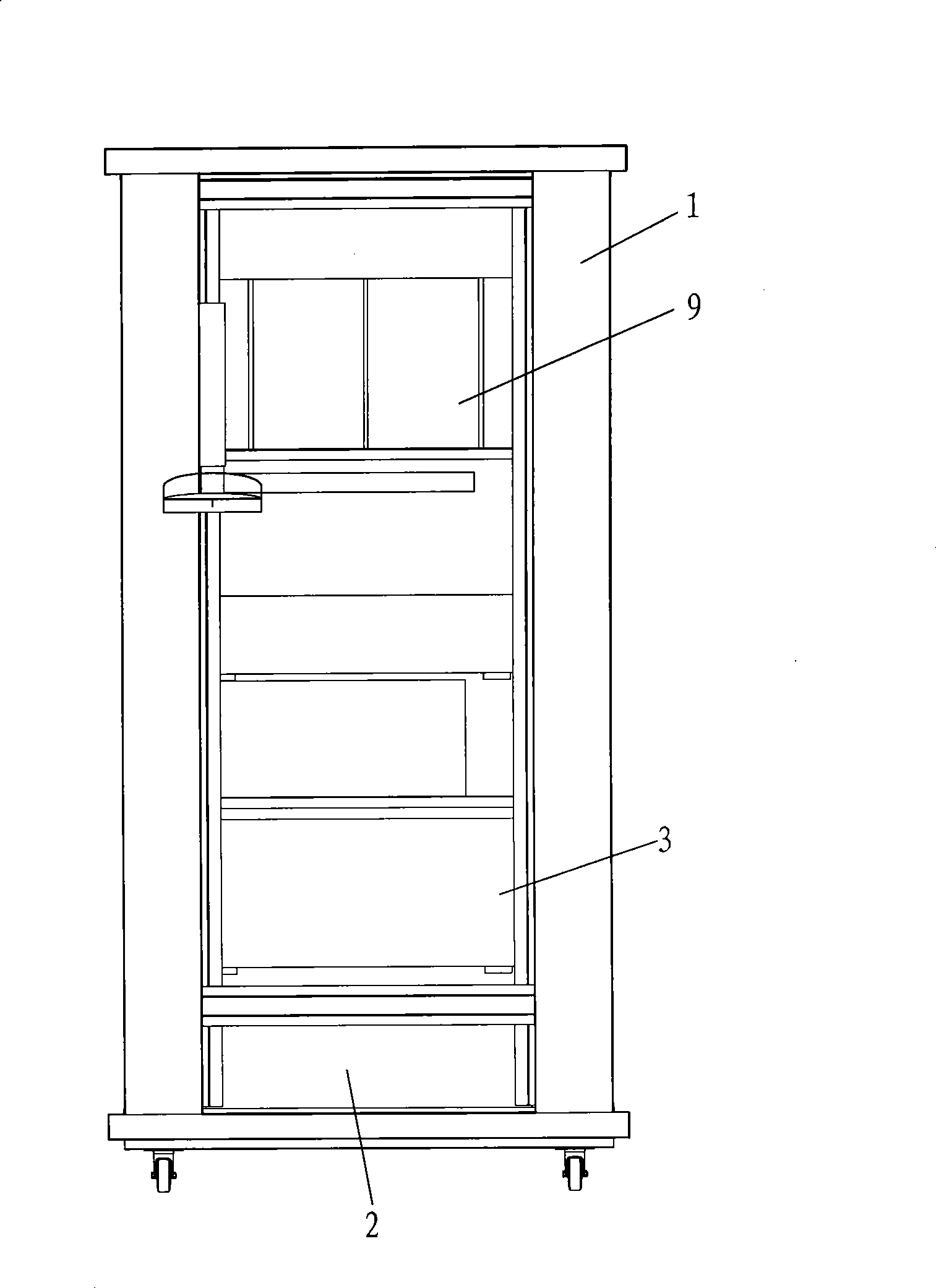

[0030] An electronic transformer automatic test system, including: cabinet 1, high and low voltage conversion box 2, programmable high voltage tester 3, computer 4, display 5, programmable AC power supply 6, keyboard 7, indicator light 8, load board 9, Relays 10, they are connected successively in the cabinet 1 from bottom to top, as Figure 1-4 as shown.

[0031] Among them, the software of computer 4 adopts NI LabVIEW as the software development platform. LabVIEW (Laboratory Virtual instrument Engineering) is a graphical programming language. It presets and edits parameters, and has a password protection function. Record. LabVIEW is a program development environment, similar to C and BASIC development environments. The characteristics of LabVIEW are: other computer languages use text-based languages to generate codes, while LabVIEW uses the graphical editing language G to write programs, and the generated programs is in block diagram form. Like C and BASIC, LabVIEW is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com