Photomask manufacturing method, pattern copy method, photomask and data base

A manufacturing method, pattern data technology, applied in the photoengraving process of the pattern surface, the original for photomechanical processing, the manufacture of semiconductor/solid state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, the best mode for carrying out the present invention will be described.

[0085] [Summary of Manufacturing Method of Photomask Related to the Present Invention]

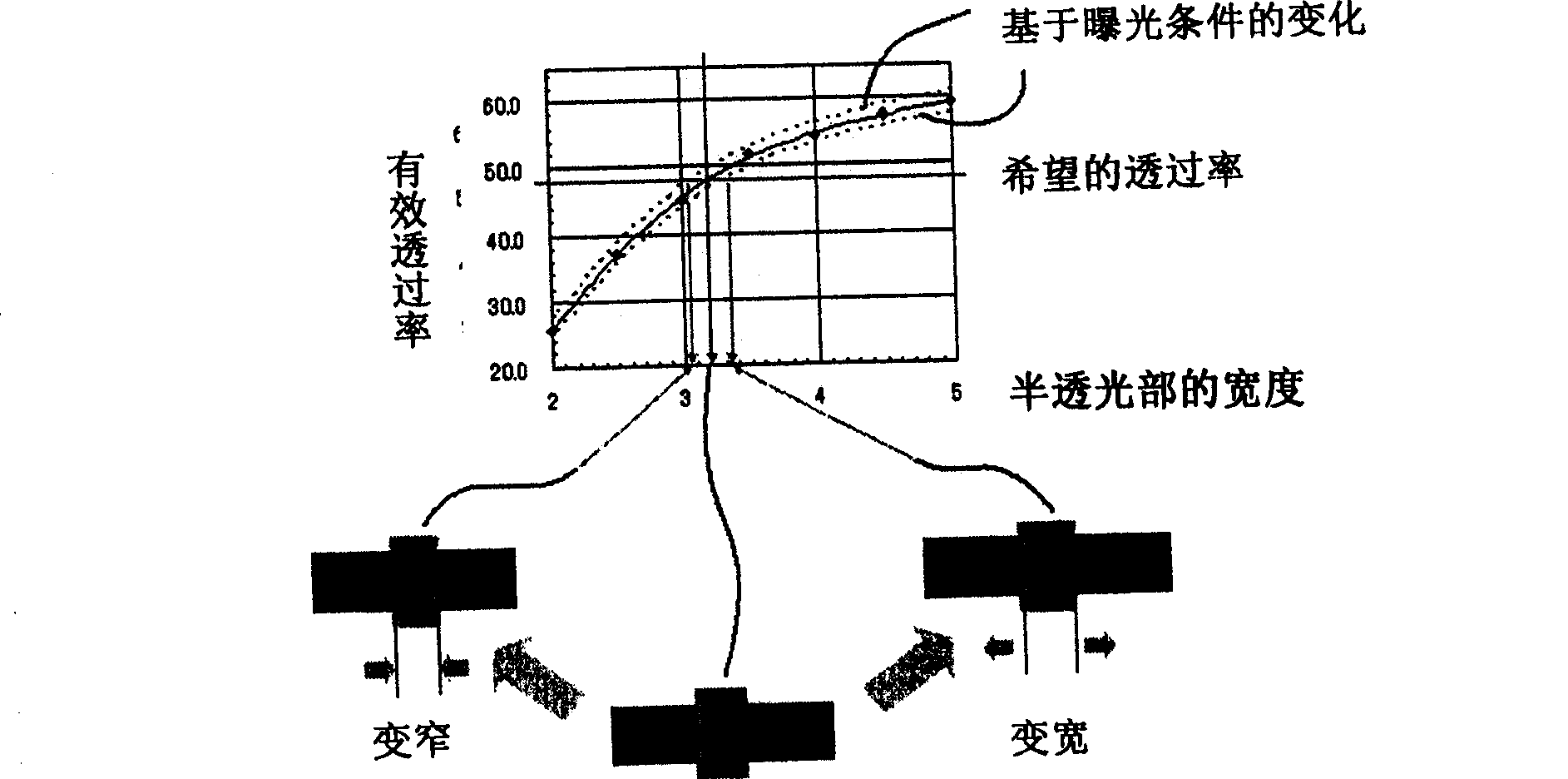

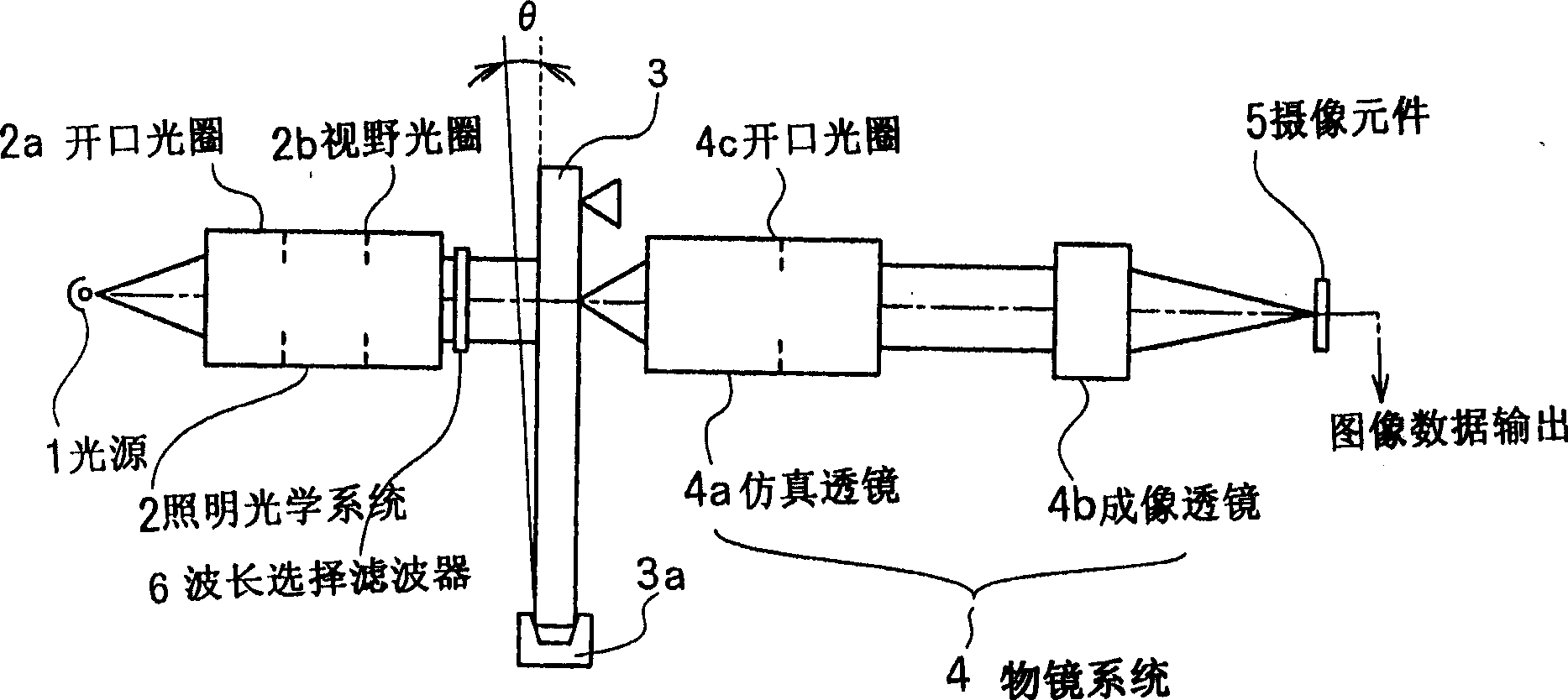

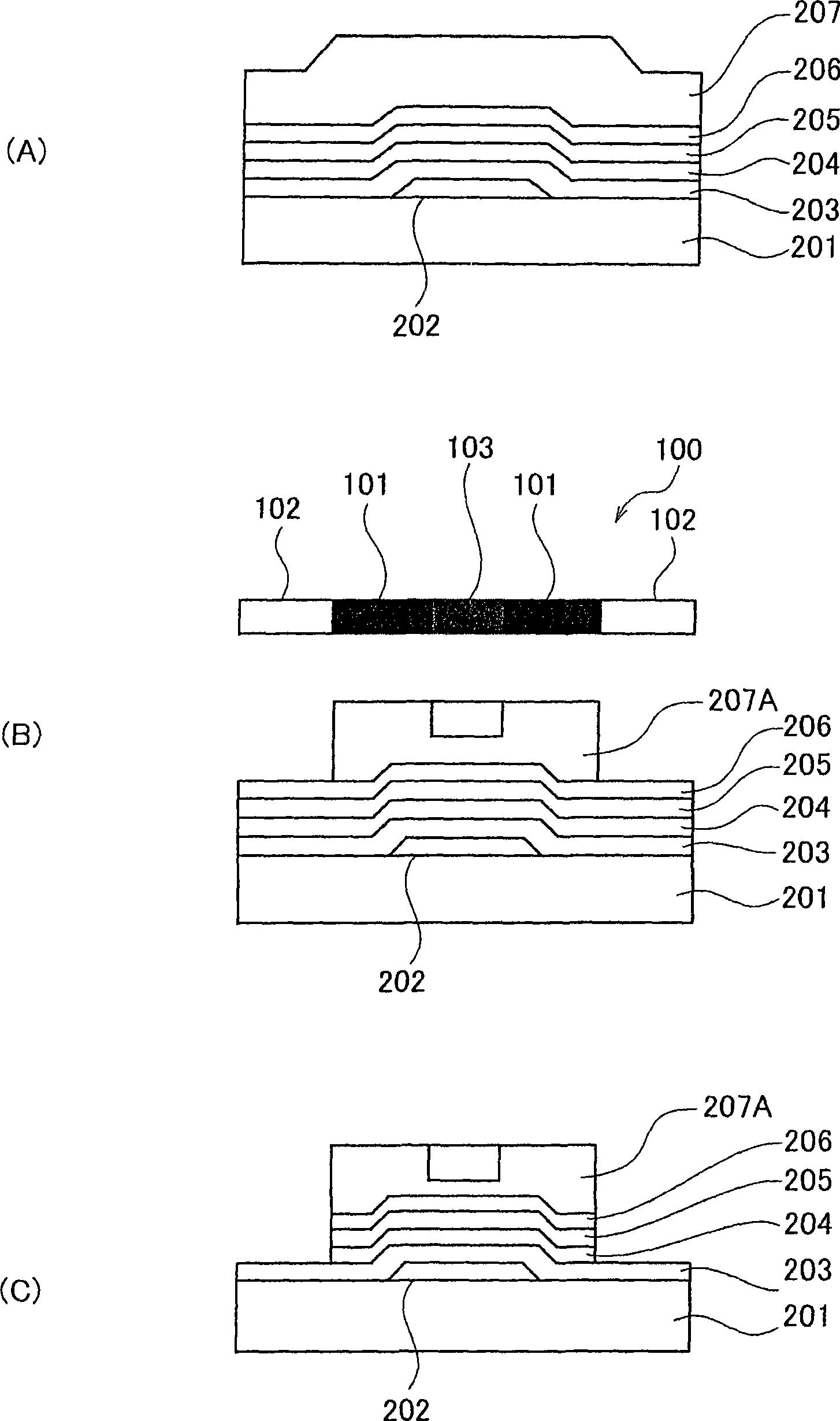

[0086] According to the method for producing a photomask of the present invention, whenever a photomask having a predetermined pattern is used on a transparent substrate to be copied (a desired film is formed on a glass substrate or the like and covered with a resist film) ) When using an exposure device for exposure, the pattern copied on the object to be copied is predicted based on the light intensity distribution captured by the imaging unit through the exposure in the exposure device, and the photomask is manufactured based on this prediction method.

[0087] More specifically, it includes a method of making exposure conditions simulating the exposure conditions in the exposure device, and making a pattern similar to a pattern reproduced on the object to be reproduced by exposure performed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com