Production method of high precision profile steel for fork

A production method and high-precision technology, which are applied in the production field of high-precision section steel for forklift trucks, can solve the problems of uneven radial pressure in the hot-rolling method, difficult load-bearing and unsatisfactory problems for forklift truck manufacturers, and achieve lower production costs and lower production costs. Production cost, the effect of ensuring the quality of the forklift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The production method of high-precision section steel for forklifts of the present invention will be further described below in conjunction with the accompanying drawings and specific examples, but the present invention is far not limited to the following specific examples.

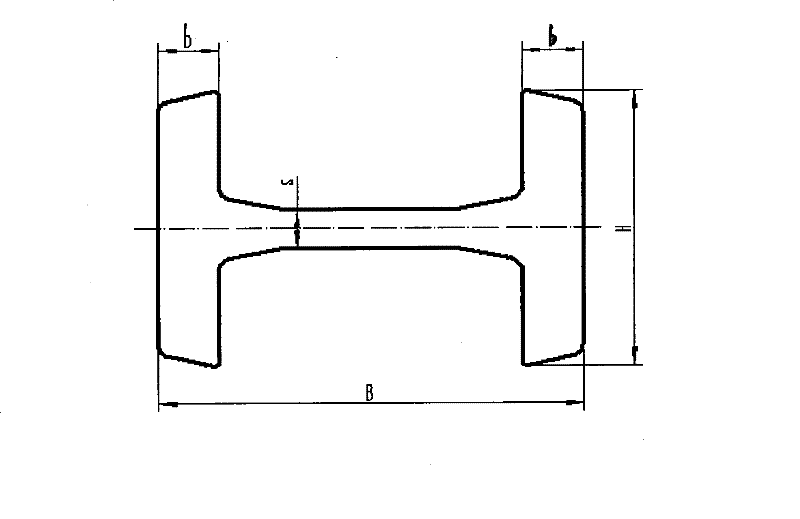

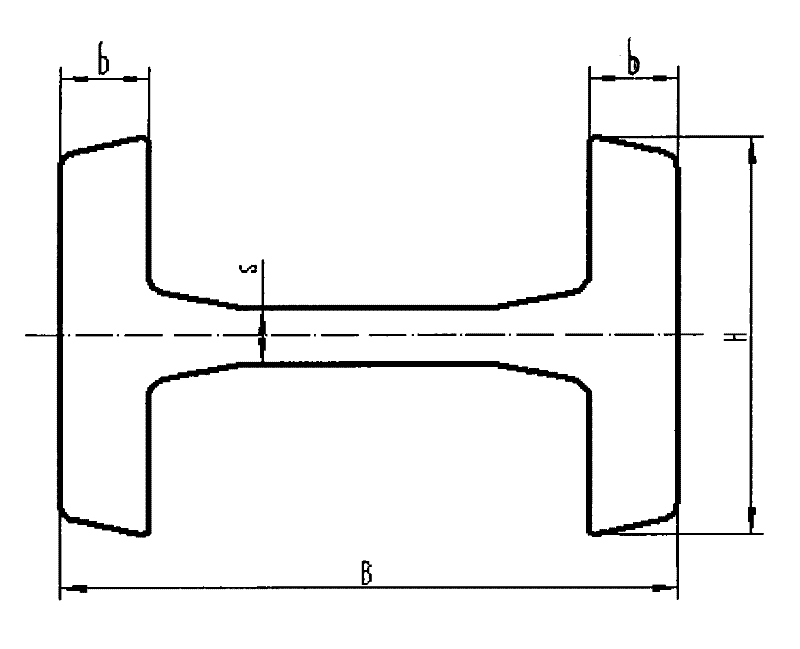

[0024] Referring to the accompanying drawings, take a specific specification of the I-shaped section steel used for cold-drawing the forklift mast as an example. The standard dimensions of each part of the cross-section of the finished section steel are: B 98mm; b 14mm; H 65mm ;S 9mm, length 8m.

[0025] Produced by cold drawing, the process steps are:

[0026] ①. The hot-rolled section steel with I-shaped cross-section is used as the blank, and the tolerance of each part of the cross-section is +1mm, that is, the size of each part of the cross-section is B 99mm; b 15mm; H 66mm; S 10mm; The length is 8m.

[0027] 2., adopt the slow-moving wire cutting method of prior art to make die head (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com