Hub unit radial numerical control rotate riveting device

A hub unit and equipment technology, applied in safety equipment, mechanical equipment, metal processing equipment, etc., can solve the problems of inconvenient maintenance, no safety protection facilities, and difficulty in ensuring the quality of riveting, and achieve the effect of simple structure and guaranteed quality of riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

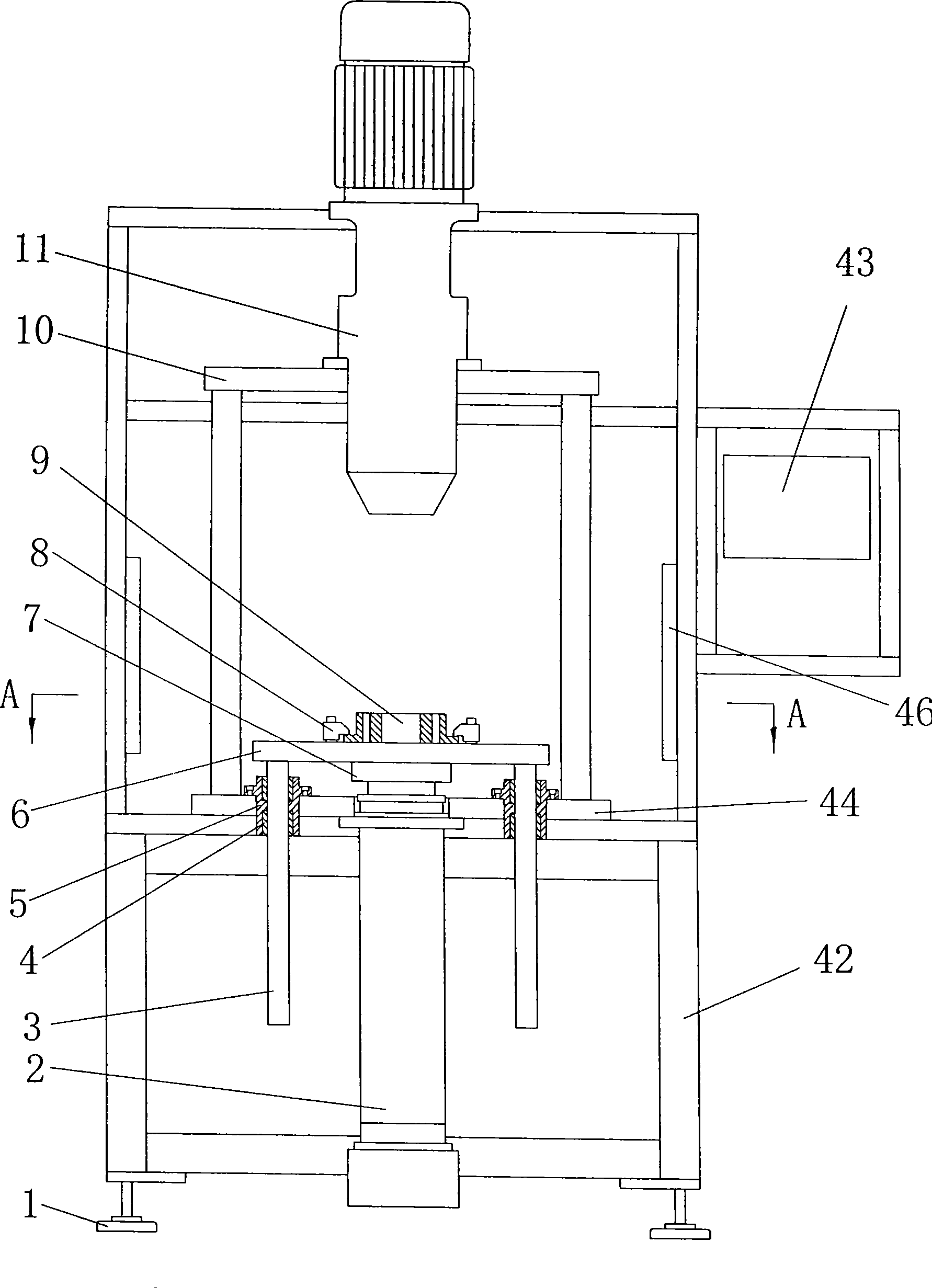

[0021] The radial spin riveting device of the present invention is a special device for flanging the flange after the hub unit is assembled. Such as figure 1 As shown, the overall structure of the present invention adopts a frame structure. The main body frame 42 of the equipment is constructed by industrial profiles, and the middle position of the main body frame 42 is provided with a platform 44 for carrying tooling and process equipment. The side of the main body frame 42 is equipped with a PLC control cabinet 43, the rear portion is provided with a main electric control box, and an automatic air conditioner is equipped in the electric control box. The bottom of the main frame is equipped with a shock absorbing pad 1 to reduce the interaction between the equipment and the environment. The vacant part around the main body frame 42 is blocked by a detachable guard plate.

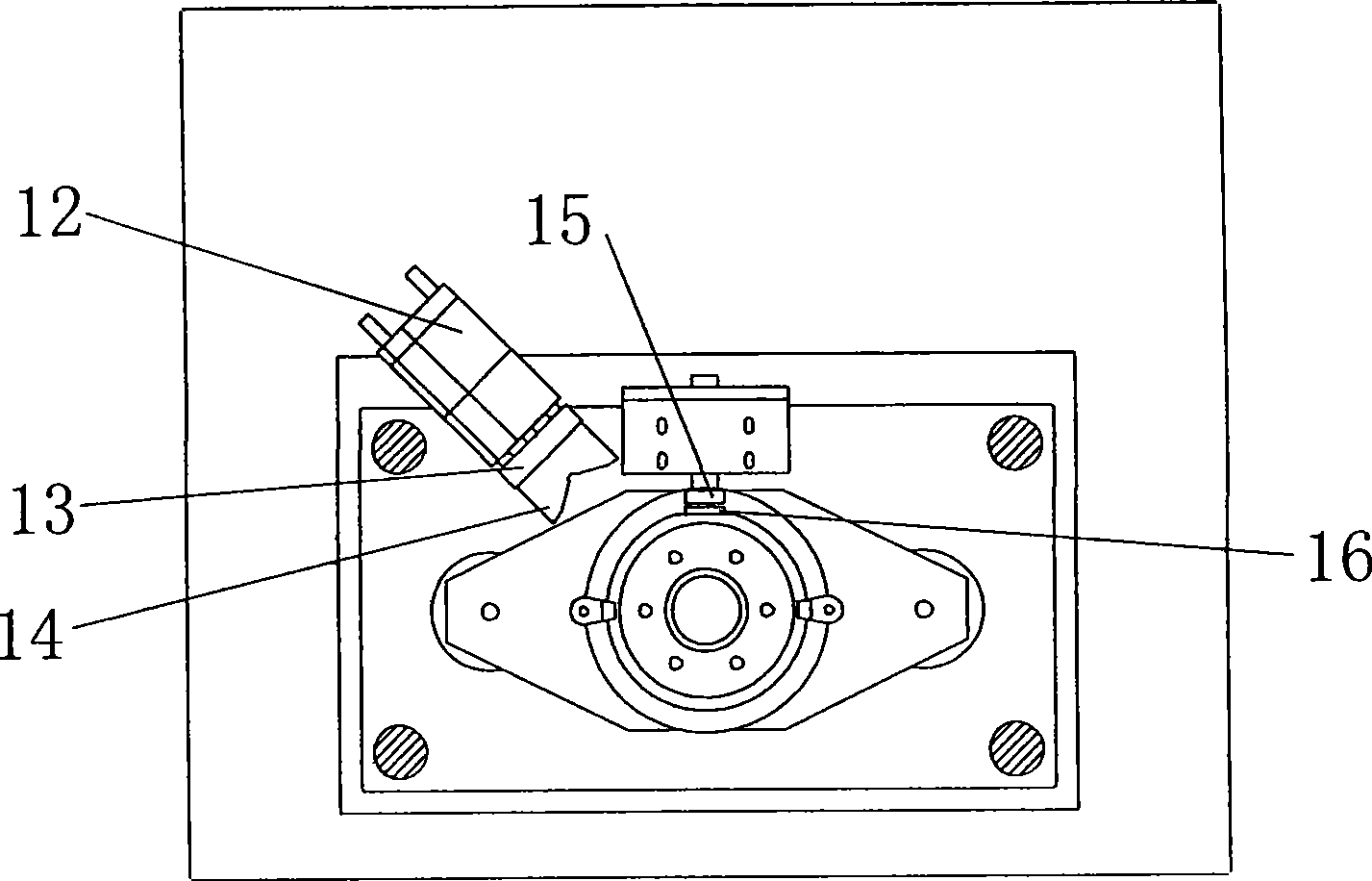

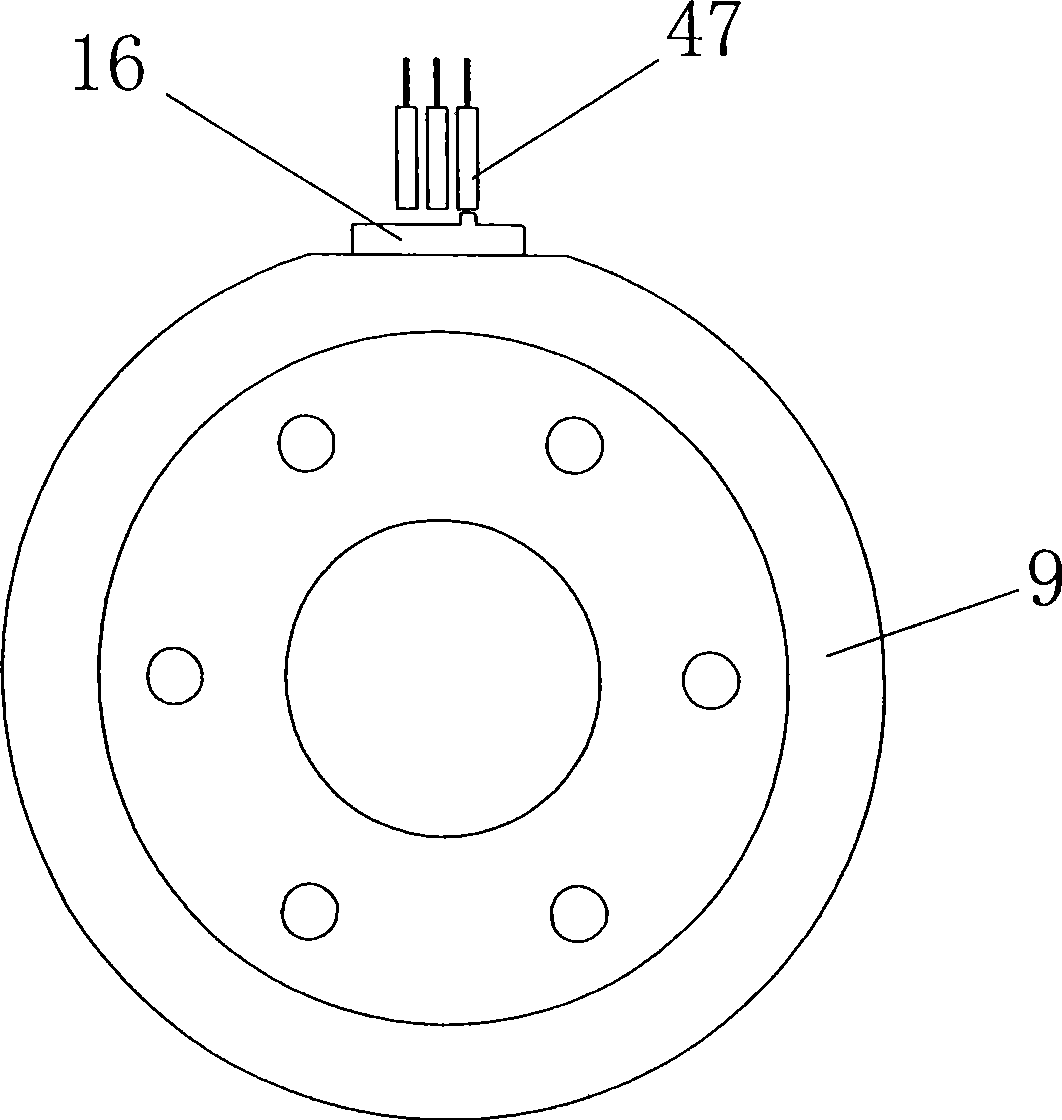

[0022] The main working parts of the equipment are carried by the platform 44 installed on the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com