Starter head for semi-continuous casting the hard aluminum alloy billet

The technology of hard aluminum alloy and dummy head is applied in the field of dummy head for semi-continuous casting of hard aluminum alloy round ingot, which can solve the problems of high crack tendency of hard aluminum alloy round ingot, leakage of aluminum, and difficulty in successful casting, etc. Significant economic and social effects, easy installation and use, long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

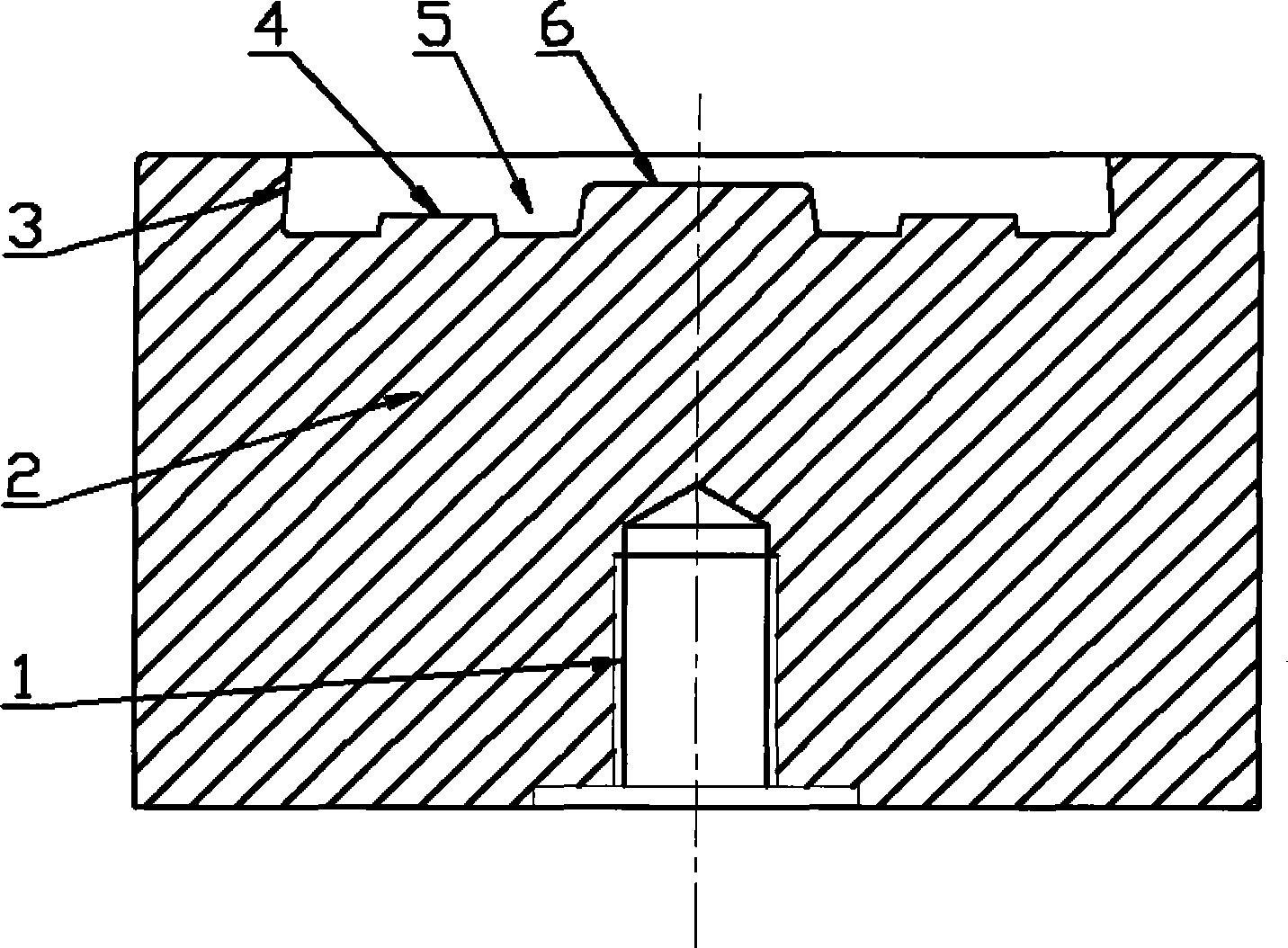

[0019] Such as figure 1 The shown dummy head for semi-continuous casting of hard aluminum alloy round ingot is made of steel material and has a cylindrical structure, including base connection thread 1, dummy body 2, cavity 5, and the boss in the cavity. A cavity 5 is opened on the upper part of the dummy body 2, and the circumferential surface of the cavity 5 is a conical surface 3 of -2~-10°. The bottom surface of the cavity 5 is provided with a central boss 6 and an annular boss 4, and the center convex Both the peripheral surface of the platform 6 and the peripheral surface of the annular boss 4 form a conical surface of 1-30°, and the radius of the annular boss 4 is half of the radius of the cavity 5 . A connecting thread 1 is provided at the bottom of the dummy body 2 , and the dummy body 2 is fixed on the supporting platform through the connecting thread 1 .

[0020] The outer periphery of the upper cavity 5 of the dummy body 2 is a negative cone surface 3 of -2~-10°, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com