Rubber composition and vibration damping material

A rubber composition and rubber technology, which is applied in the field of rubber composition and shockproof materials, can solve the problems that the shockproof materials cannot be fully adapted, and achieve the effect of excellent shockproof and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

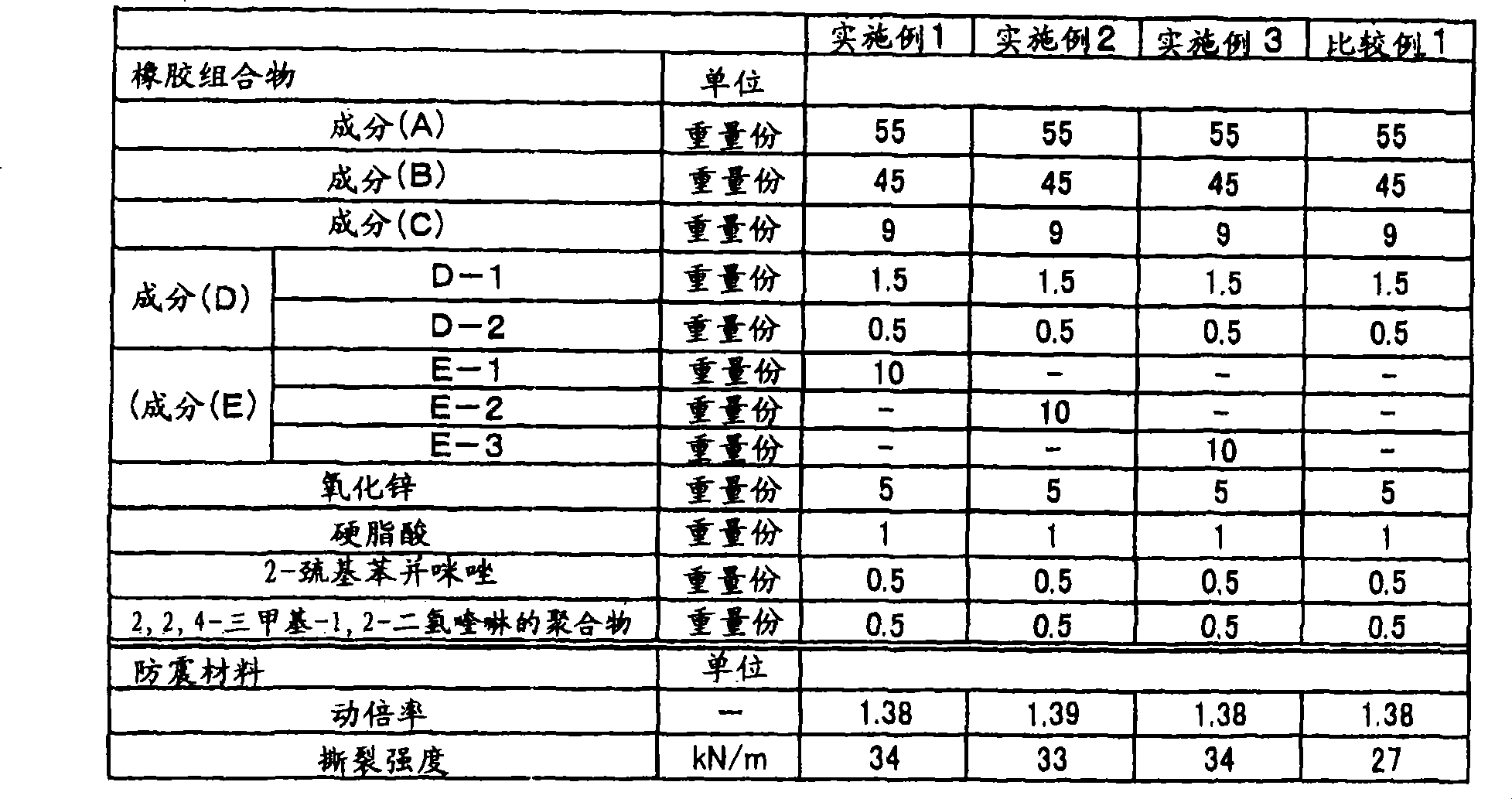

Embodiment 1

[0089] (modulation of rubber combination)

[0090] 55 parts by weight of ethylene-propylene-5-ethylene-2-norbornene copolymer rubber as component (A), 45 parts by weight of natural rubber as component (B), 4,4 1.5 parts by weight of '-bis(α, α-dimethylbenzyl) diphenylamine and 0.5 parts by weight of N, N'-di-2-naphthyl-p-phenylenediamine, aluminum silicate ( SOUTHEASTERN CLAY company manufactures クラウンクレ—) 10 parts by weight, zinc oxide 5 parts by weight, stearic acid 1 part by weight, 2-mercaptobenzimidazole 0.5 parts by weight and 2,2,4-trimethyl-1,2-bis 0.5 parts by weight of the hydroquinoline polymer was put into a 1700 mL Banbury mixer whose initial temperature was adjusted to 80° C., and kneaded for 5 minutes at a rotor speed of 60 rpm to obtain a kneaded product. Then, 9 parts by weight of dicumyl peroxide (40% diluted product) was added to the kneaded product with respect to 100 parts by weight of the total amount of component (A) and component (B) as component (C). ...

Embodiment 2

[0094] As the component (E), 10 parts by weight of aluminum silicate (Burgess Pigment Co., Ltd. バゲスクレ-30) was used instead of aluminum silicate (SOUTHEASTERN CLAY Co., Ltd. Co., Ltd. クラウンクレ-), except that the same operation as in Example 1 was carried out. , making cross-linked sheets. Table 1 shows the evaluation results of the obtained crosslinked sheet.

Embodiment 3

[0096] Except having used 10 weight part of aluminum hydroxides instead of aluminum silicate as a component (E), it carried out similarly to Example 1, and produced the crosslinked sheet. Table 1 shows the evaluation results of the obtained crosslinked sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com