Application of laser heat treatment technology in marine diesel cylinder liner

A marine diesel engine and laser heat treatment technology, which is applied in the application field of laser heat treatment technology in marine diesel engine cylinder liners, can solve the problems of increased inner hole wear, poor anti-cavitation performance, accidents, etc., and achieves small deformation and good sealing. and matching performance, the effect of improving wear resistance and anti-cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

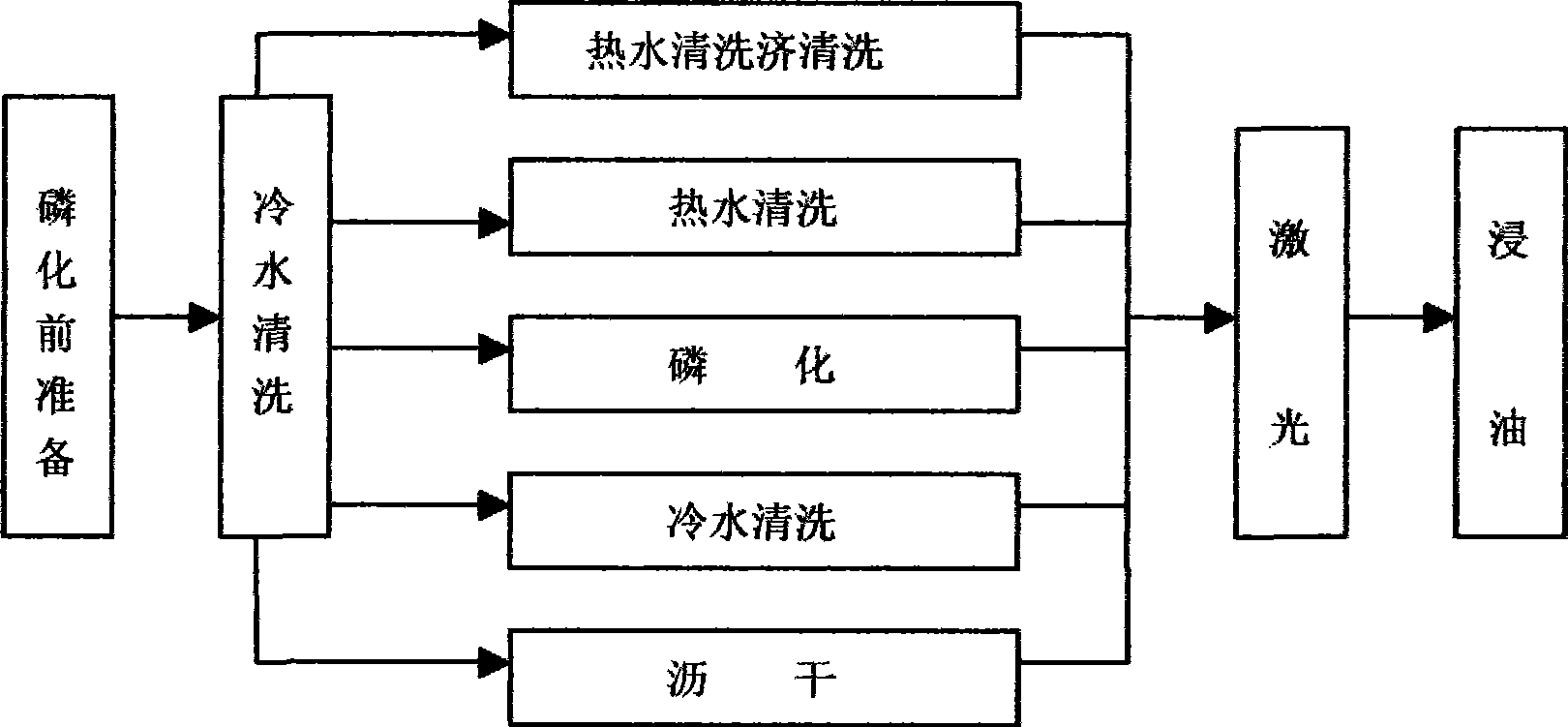

[0009] 1. Preparation before phosphating

[0010] Before phosphating of the finished cylinder liner, the inner hole must have a relatively high roughness, the smoother the better, and it must be cleaned before phosphating.

[0011] 2. Phosphating

[0012] In order to fully absorb the laser scanning, the cylinder liner must be phosphated black, and the depth of the black must be consistent, otherwise the quality of the laser scanning will be affected.

[0013] (1) Cleaning with hot water detergent

[0014] Mix 3%-5% cleaning agent (powder) with water, heat the water to 60°C-80°C, then put the cylinder liner into the water and soak for 15 minutes.

[0015] (2) hot water washing

[0016] Heat the water to 75°C-100°C, put the cylinder liner into the pool and soak for 4-5 minutes.

[0017] (3) Phosphating

[0018] According to the product requirements, mix the phosphating solution and water in a certain proportion, heat it to 110°C-115°C, put the cylinder liner into the phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com