Damping device for a composite blade

A composite material and vibration damping device technology, which is applied to the supporting elements of blades, components of pumping devices for elastic fluids, liquid fuel engines, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

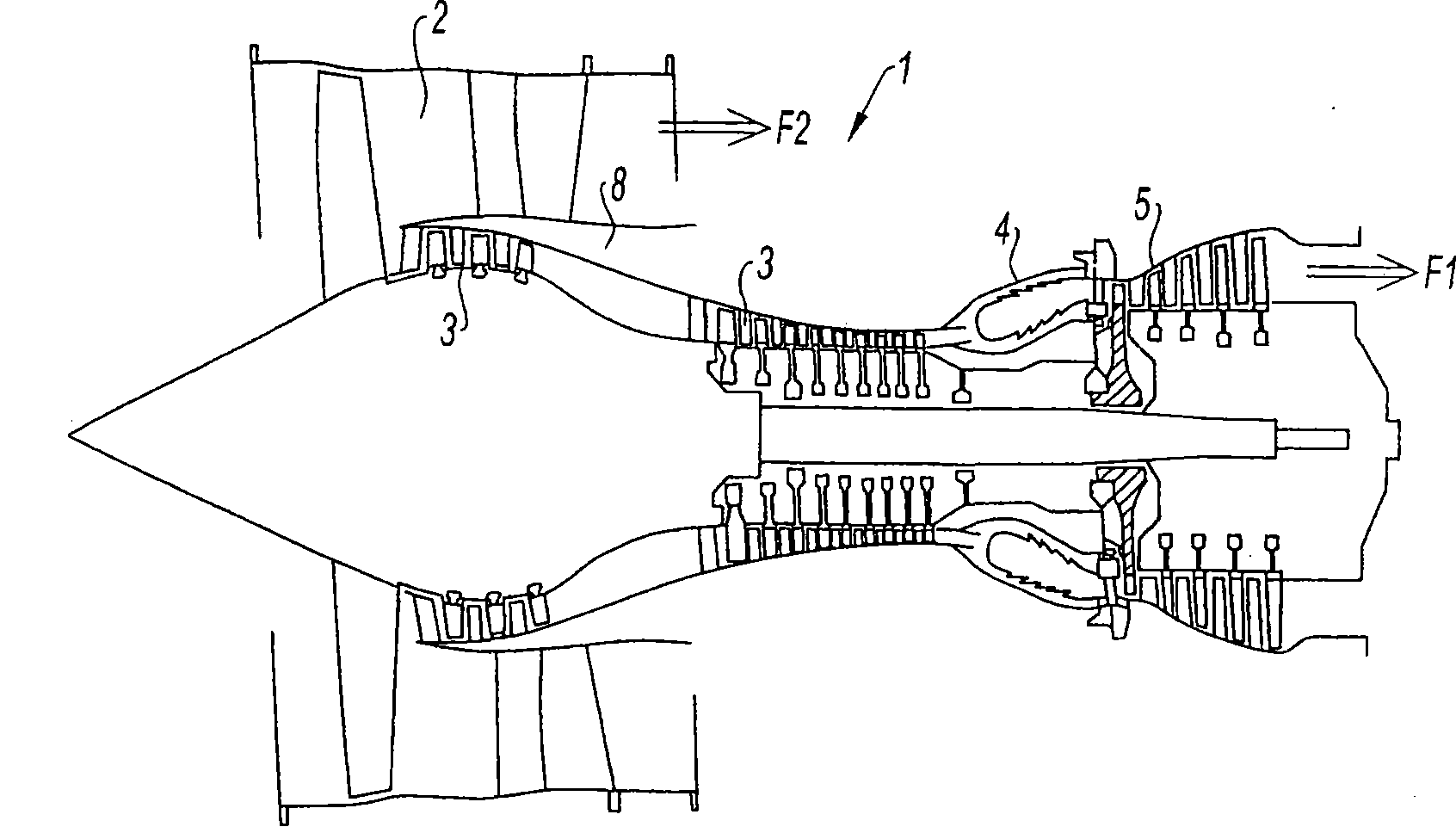

[0050] figure 1 Is a schematic diagram of a turbine, the turbine shown is a twin-rotor bypass turbojet engine 1 . Fan 2 located at the front supplies air to the engine. The air compressed by the fan enters into two concentric flow paths F1 and F2 in two paths. The secondary flow path F2 (or bypass) is directly discharged into the atmosphere and provides the main propulsion thrust. The main flow F1 is led through several compression stages 3 into a combustion chamber 4 where air is mixed with fuel and combusted. The hot gas powers each turbine stage 5, which turns the fan 2 and the compression rotor 3 in rotation. The gas is then vented into the atmosphere.

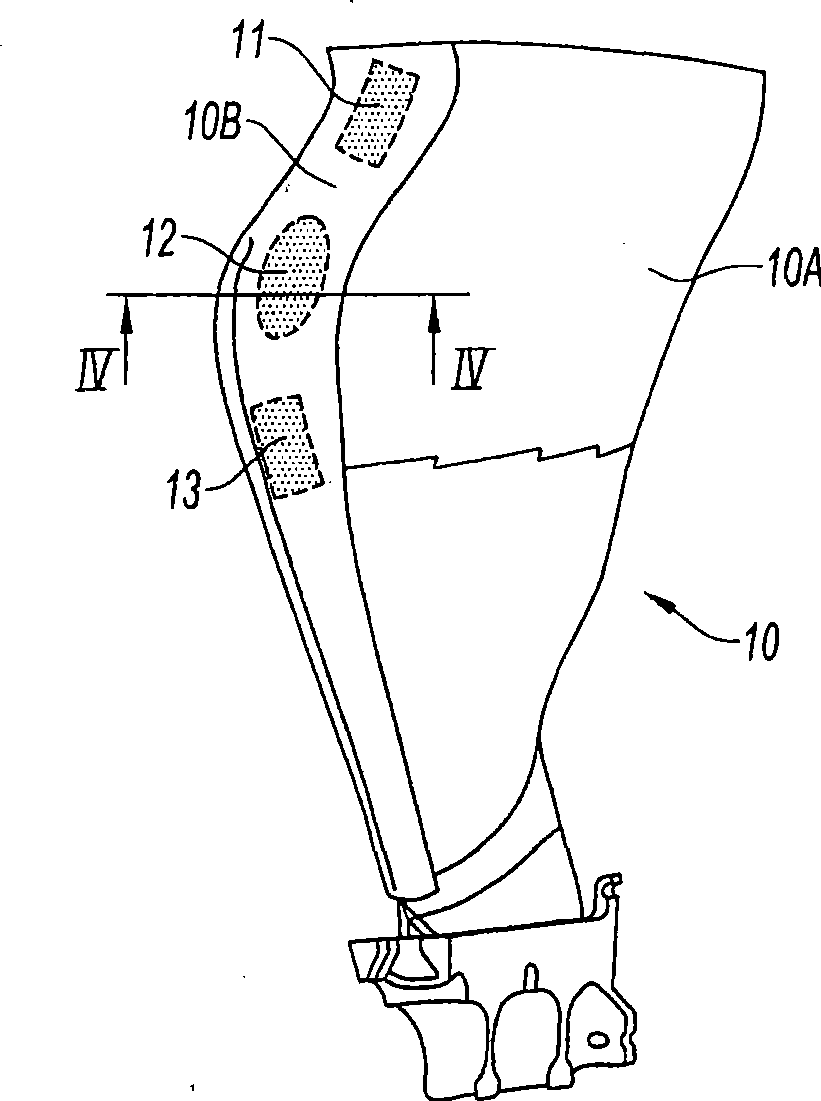

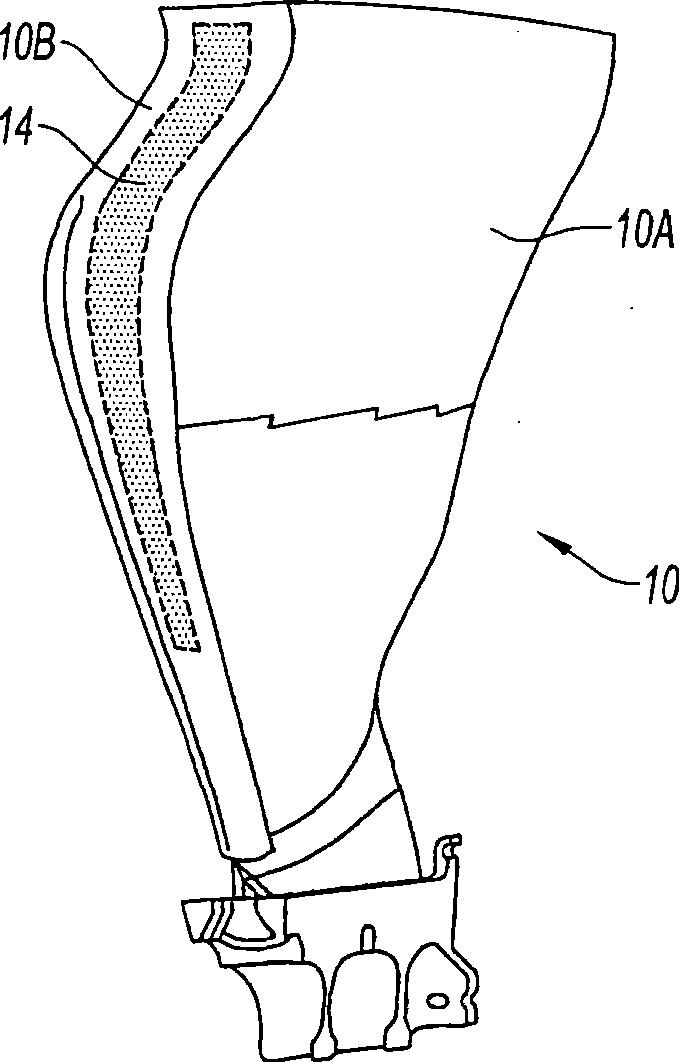

[0051] figure 2 with image 3 A fan blade 10 that may be used on such an engine is shown. This is a blade made of composite material. Typically, the composite portion 10A of the blade consists of fibers or long filaments held together with a thermosetting resin. These fibers or thin filaments are made of carbon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com