High precision micro displacement detection device for demarcating machinery deformation amount and measurement method thereof

A micro-displacement, high-precision technology, used in measuring devices, electrical devices, electromagnetic measuring devices, etc., can solve the problems of decreased measurement accuracy, low measurement result accuracy, and increased system stress, and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

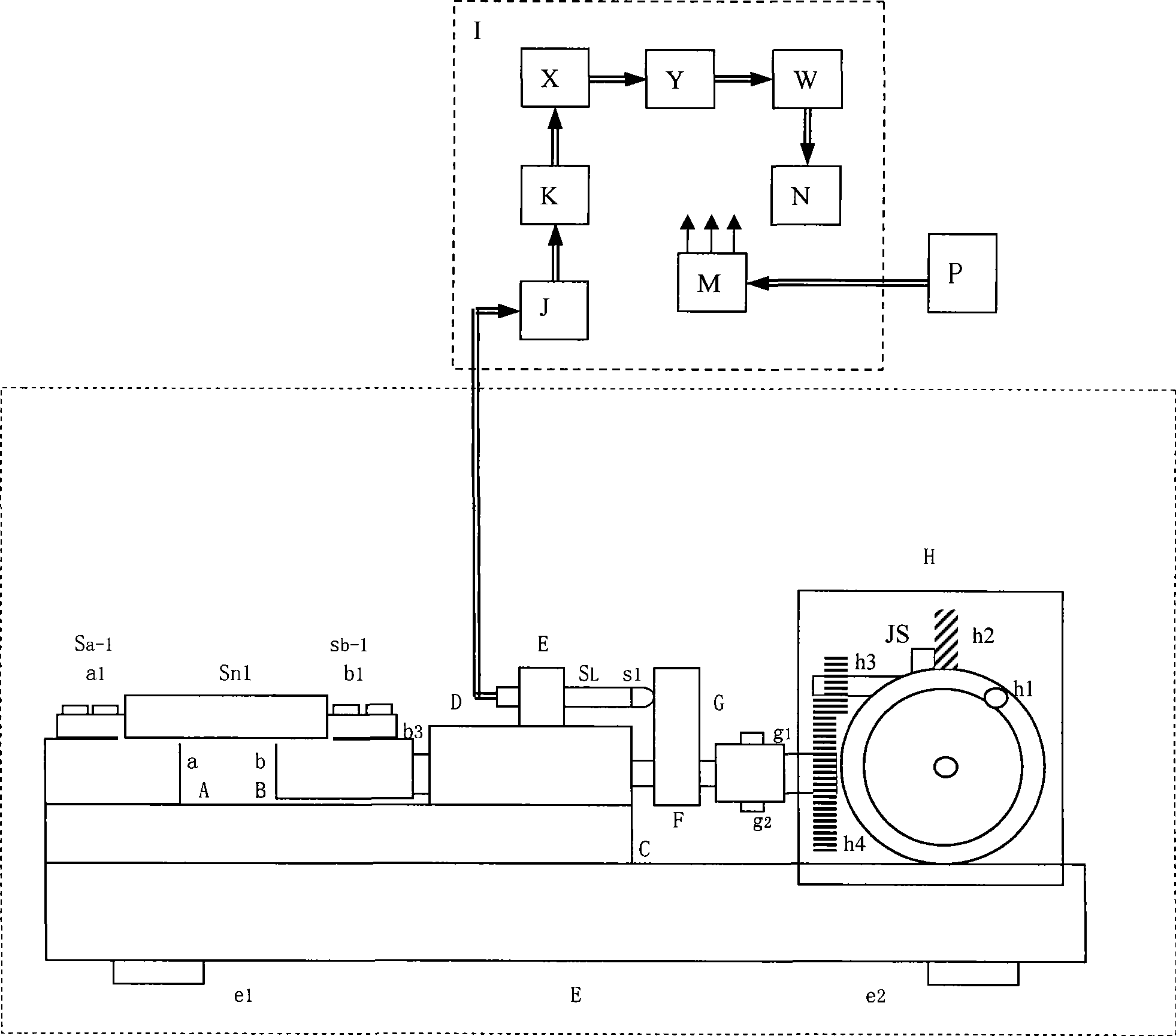

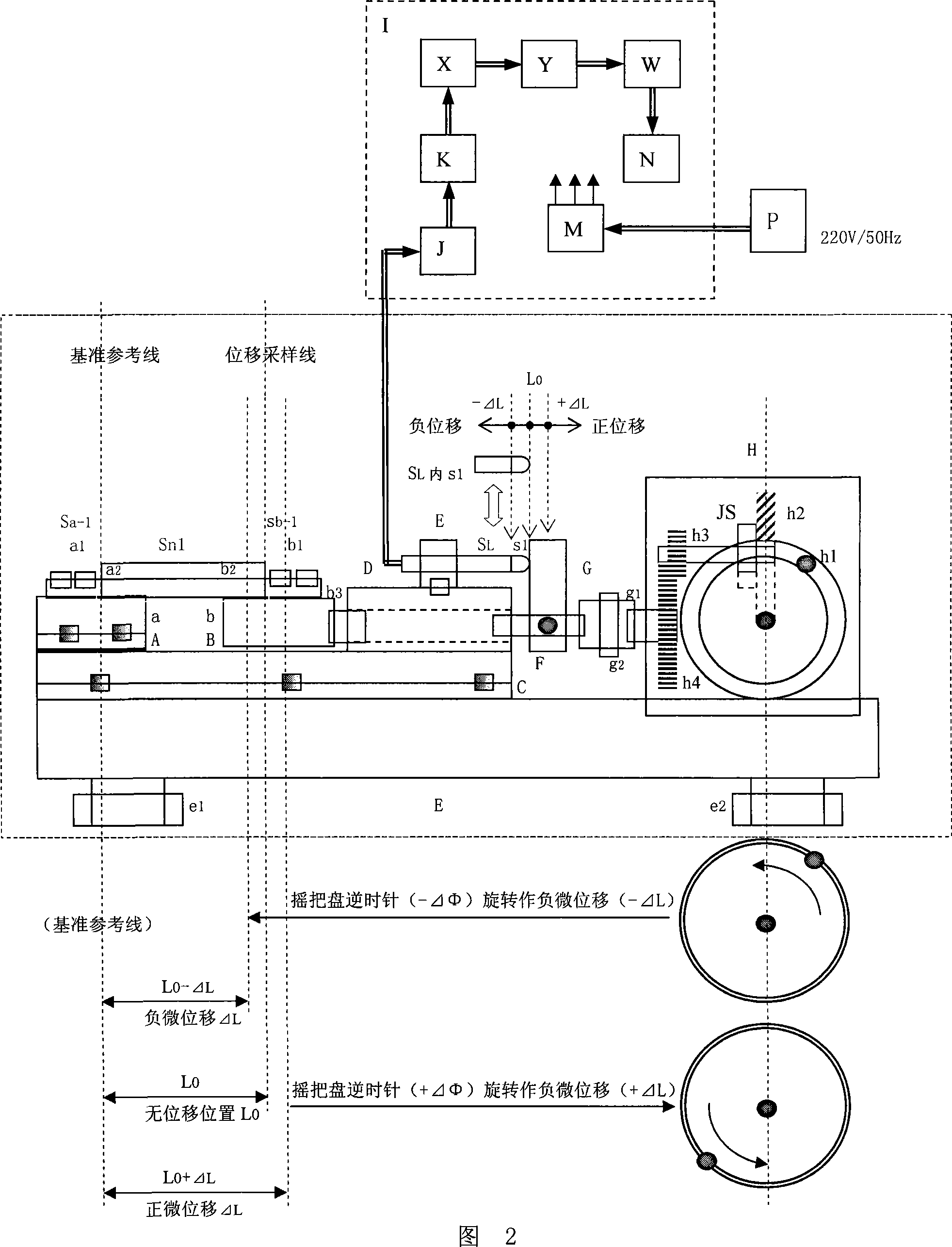

[0026] Implementation structure: The basic design idea of a high-precision micro-displacement detection device for calibrating mechanical deformation is as follows: figure 1 As shown in Figure 2, the high-precision micro-displacement detection device in the figure is composed of an electrical analysis part and a mechanical analysis part.

[0027] 1. The electrical analysis part includes: I is the electrical casing; P is the 220V / 50HZ AC power supply, which is connected to M as the input of the M part to provide power to the system; M is the internal power rectifier and regulator, whose function is to convert the P The provided AC power is converted into stable DC power, which is used as a DC voltage input, and the J phase discriminator, K high-frequency oscillator, X analog-to-digital converter, W logic processor, N micro-displacement display, The various parts of the SL inductive micro-displacement sensor are connected to provide a stable DC power supply to ensure the energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com