Powder-spraying device for producing low-light-level image intensifier luminescent screen powder-layer

A low-light image intensifier and fluorescent screen technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficulty in controlling the amount of powder, waste of fluorescent powder, and poor effect of dusting on the filter. Achieve the effect of overcoming agglomeration and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

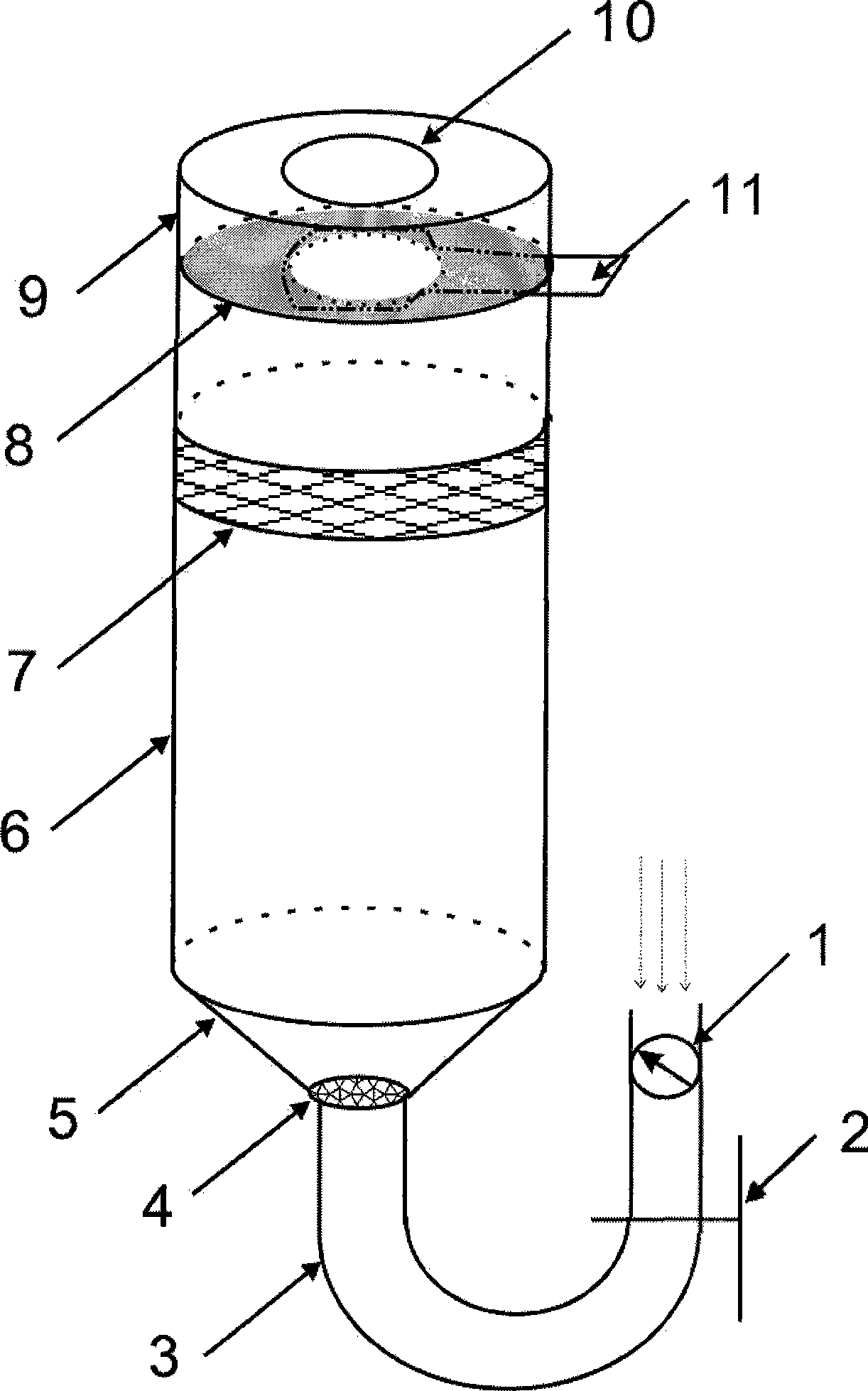

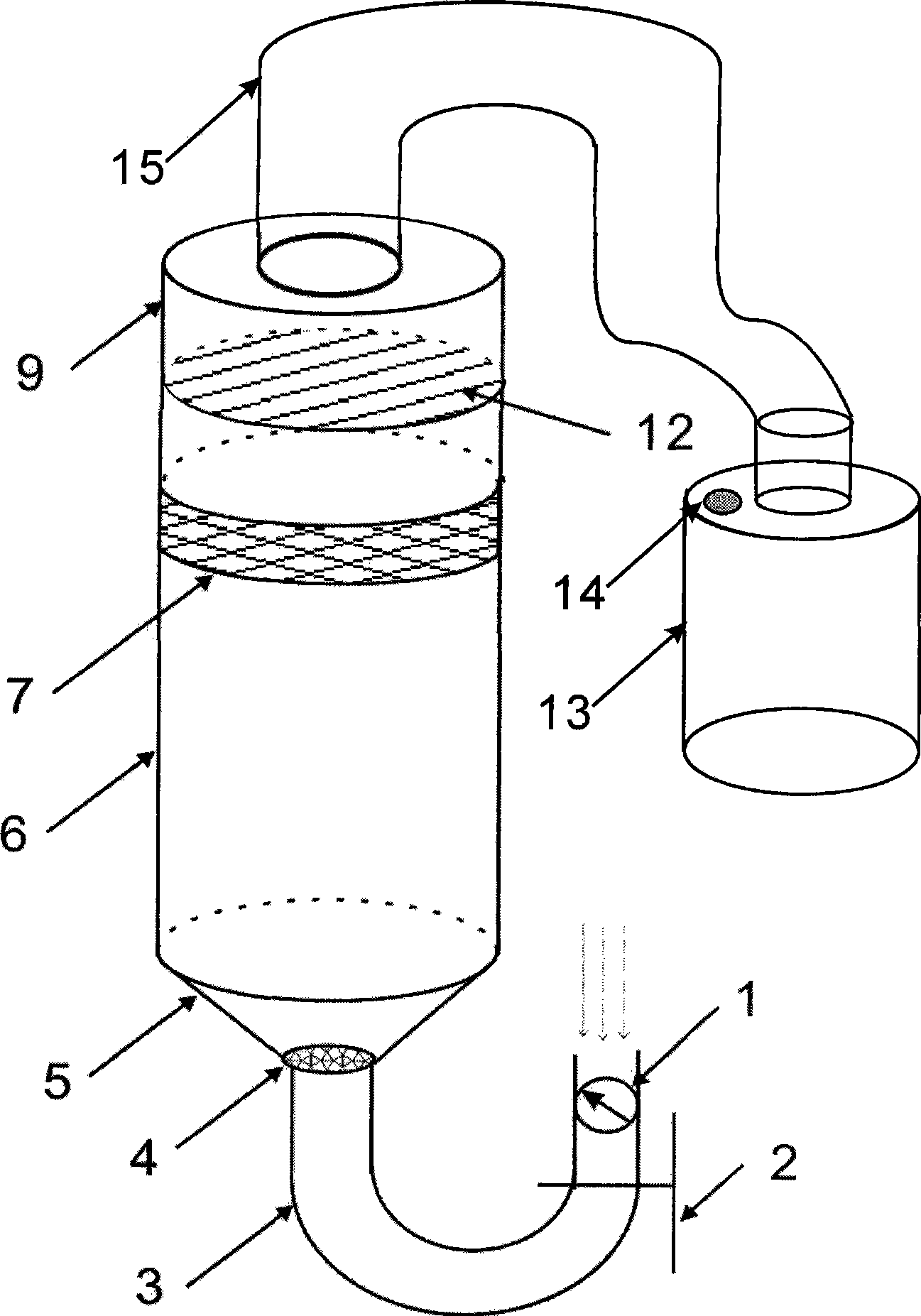

[0016] as figure 1 As shown, the preferred embodiment of the powder spraying device of the present invention is composed of an air intake assembly, a powder spraying chamber 6 and a fluorescent screen fixture 9 . The intake assembly includes a pressure reducing valve 1, a solenoid valve 2, a U-shaped pipe 3 made of stainless steel, a first filter screen 4, and a frustum-shaped shell seat 5 made of stainless steel. The internal diameter of U-shaped pipe 3 is 5~10mm, and its one end is connected with the small mouth end of conical shell seat 5 and the first filter screen 4 is housed in the connection position, and the other end is air inlet then installs decompression valve 1 and electromagnetic valve 2. The powder spraying chamber 6 is a glass cylinder, and its inner diameter and height can be determined according to the area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com