Aloe polysaccharide extraction method and use thereof in cigarette

A technology of aloe polysaccharides and extraction methods, applied in the fields of application, tobacco, and preparation of tobacco, etc., can solve the problems of no tobacco application precedents, and achieve the effects of reducing the content of harmful substances, improving comfort, and improving the quality of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

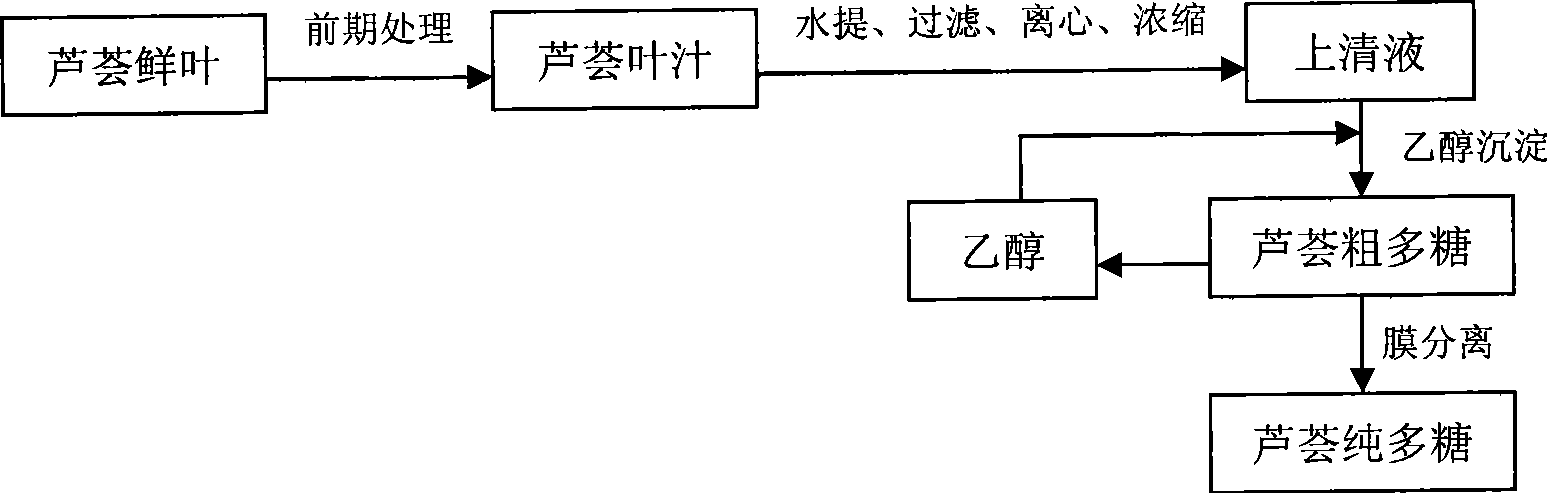

[0023] 1. Take the fresh leaves of aloe vera, rinse them with deep well water, dry them in the air, and after 6 minutes of ultraviolet sterilization, use a high-speed pulverizer to crush the fresh leaves of aloe vera into a thin slurry. Then use a high-speed sedimentation machine for precipitation treatment. Then filter or vacuum filter to become pure aloe juice.

[0024] 2. Use water with a volume ratio of 1:2, microwave extraction for 10 minutes, filter the extract and centrifuge it in an industrial centrifuge at 1000 rpm for 15 minutes, take the supernatant and concentrate it to 1 / 10 of the original volume;

[0025] 3. Add the concentrated supernatant to 95% ethanol, stir for 5 minutes, let stand for 2 hours, filter and recover the ethanol, collect and precipitate the crude polysaccharide of aloe, wash the filter cloth with water for 3 times, and combine the washing liquid with the crude polysaccharide. Stir and dissolve to obtain a crude polysaccharide aqueous solution, f...

Embodiment 2

[0030] 1. Take the fresh leaves of aloe vera, rinse them with deep well water, dry them in the air, and after 8 minutes of ultraviolet sterilization, crush the fresh leaves of aloe vera into a thin slurry with a high-speed pulverizer. Then use a high-speed sedimentation machine for precipitation treatment. Then filter or vacuum filter to become pure aloe juice.

[0031] 2. Use water with a volume ratio of 1:3, microwave extraction for 20 minutes, filter the extract and centrifuge it in an industrial centrifuge at 2000 rpm for 15 minutes, take the supernatant and concentrate it to 1 / 20 of the original volume;

[0032] 3. Add the concentrated supernatant to 98% ethanol, stir for 8 minutes, let stand for 3 hours, filter and recover the ethanol, collect and precipitate the aloe crude polysaccharide, wash the filter cloth with water for 3 times, and combine the washing liquid with the crude polysaccharide. Stir and dissolve to obtain a crude polysaccharide aqueous solution, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com