Improved polyester monofilament production method

A production method, polyester monofilament technology, applied in the field of polyester monofilament production, can solve the problems of frequent fragments, poor resilience, and many product defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

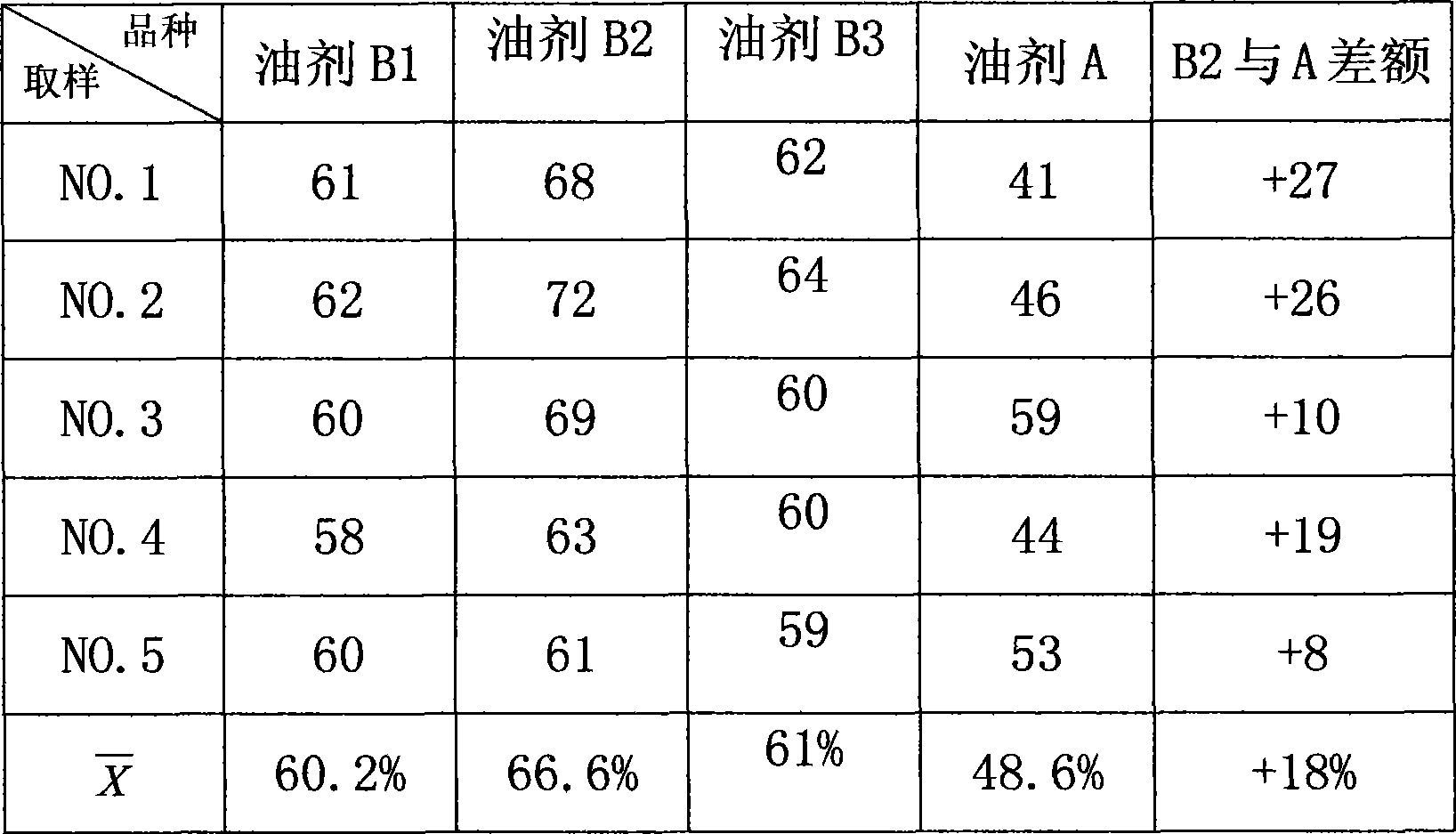

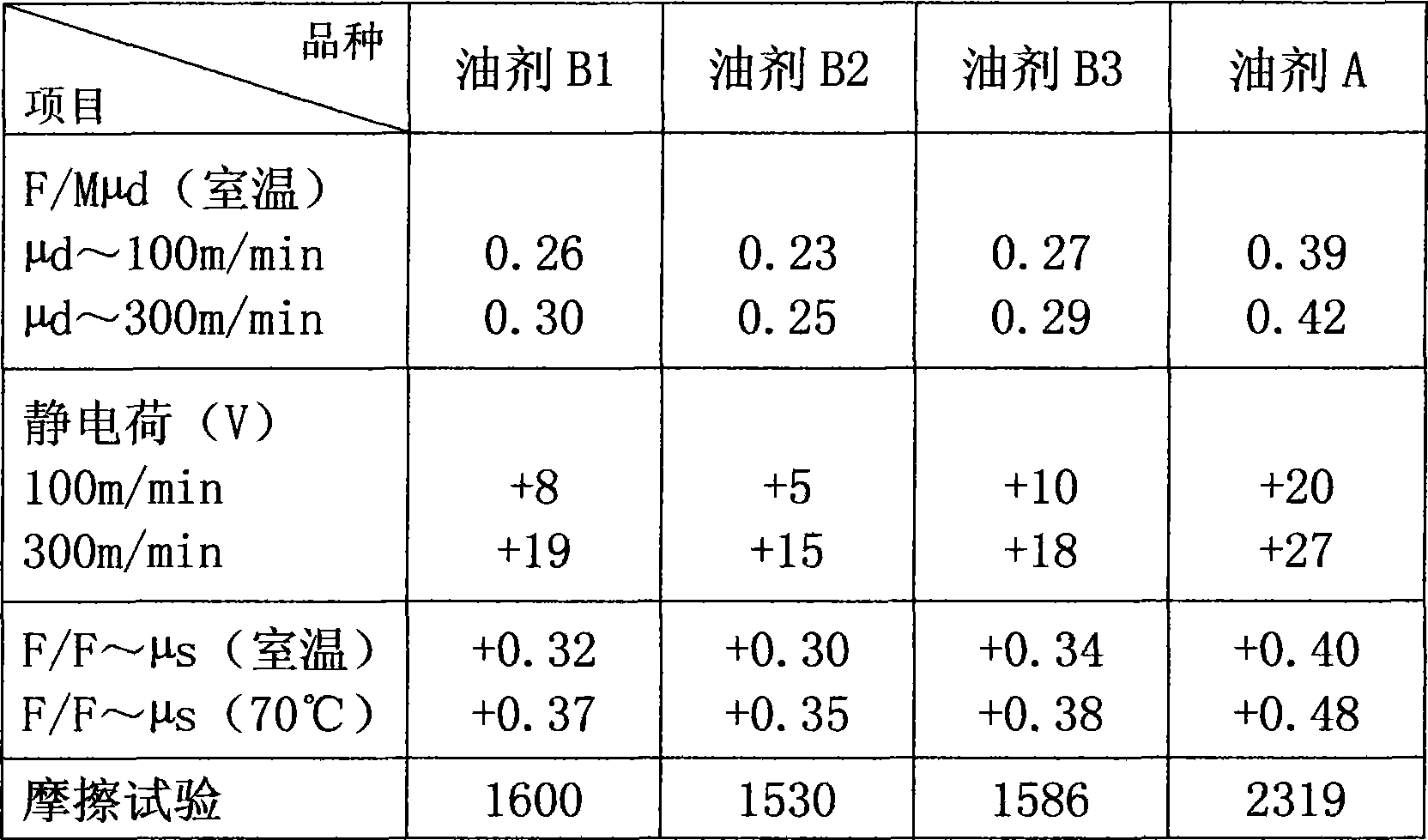

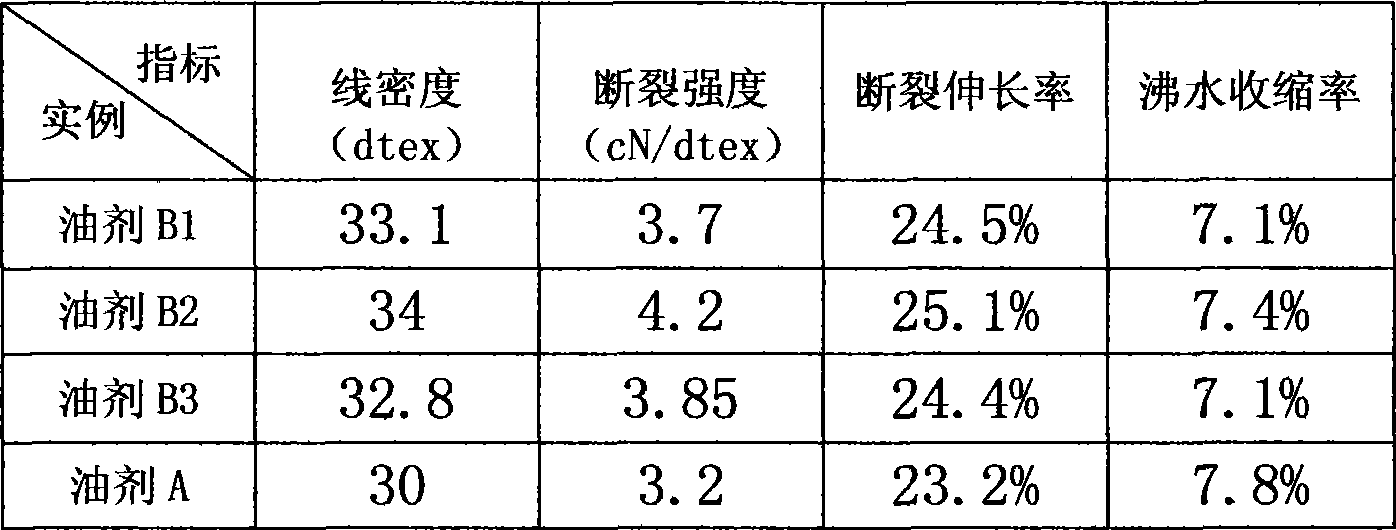

[0007] The present invention adopts the mixture of polyether and ester (hereinafter referred to as oil agent B) to improve monofilament, and this oil agent is made of 23%~25% mineral oil (smooth agent), 14%~16% lauric acid oil Alcohol ester (smooth agent), 39% to 41% polyether (smooth agent), 0.5% to 1.5% sodium alkylsulfonate (antistatic agent), 0.2% to 1.8% potassium salt of POE alkyl phosphate (wetting agent), 7.5% to 8.5% laurate (emulsifier), 7.5% to 8.5% POE oleyl ether (emulsifier) and 1.5% to 2.5% oleyl alcohol (regulator), It not only has the functions of oil agent A, but also has strong emulsion stability, greatly improving oil corruption; good permeability, can be quickly and evenly mixed with water; small surface tension, uniform false twist and reduce fuzz The effect; the special antistatic agent sodium alkyl sulfonate added to the oil reduces the amount of tar in production and softens the tar on the hot plate, making it easy to wash off the tar, thereby reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com