Non-contact oil layer thickness detecting method

A technology of oil layer thickness and detection method, which is applied in measurement devices, liquid/fluid solid measurement, liquid level indicator for physical variable measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

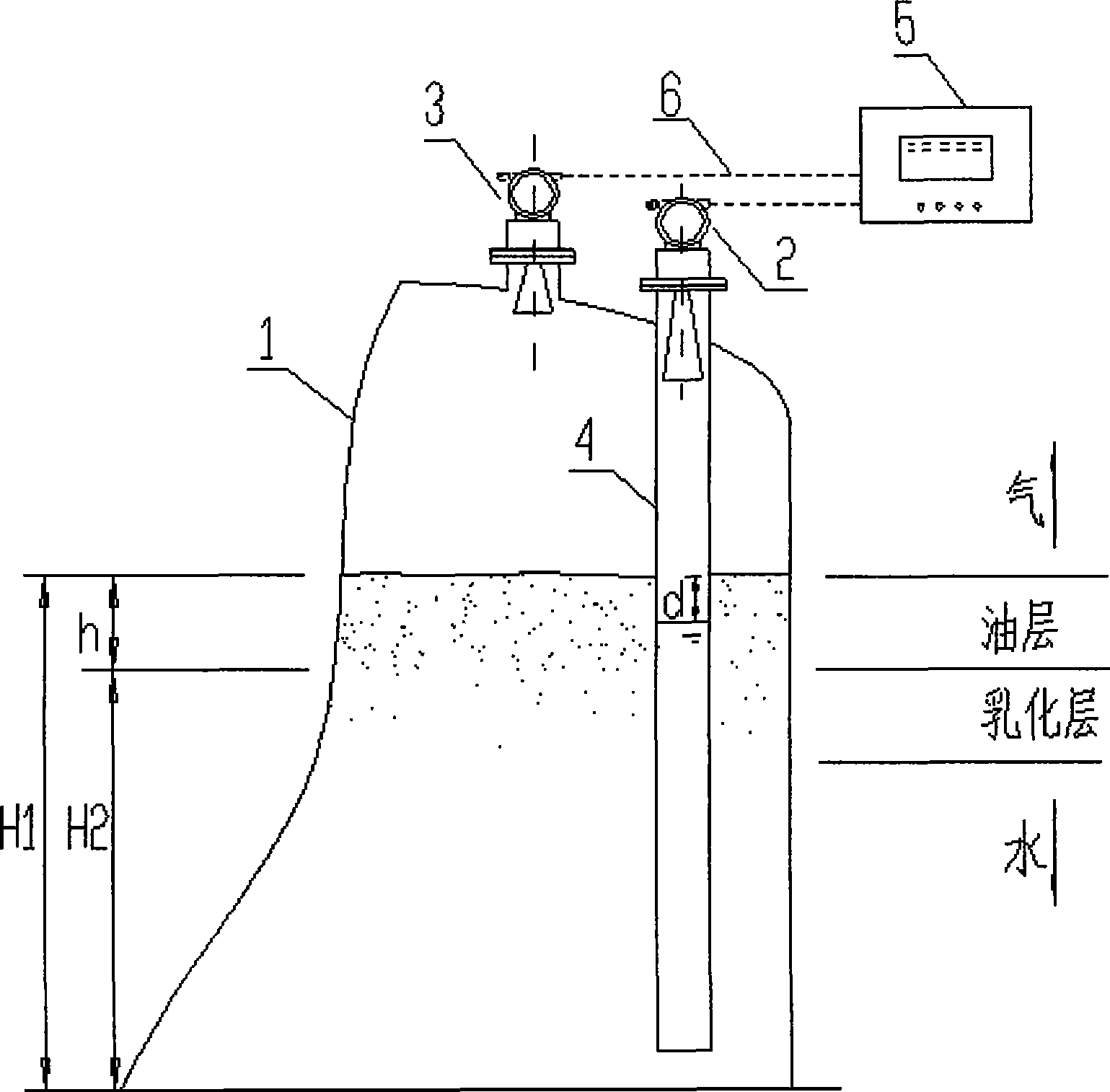

[0017] Such as figure 1 As shown, the interior of the water-containing oil tank 1 (which may be a lying tank or a pond) is respectively a gas phase space, an oil layer, an emulsified layer, and a water layer from top to bottom. The first liquid level detection instrument 2 and the second liquid level detection instrument 3 are respectively installed on the top of the tank (or pool top), and the second liquid level detection instrument 3 is at the top of the tank. The first liquid level detection instrument 2 is installed on the top of the oil layer isolation cylinder 4 . The first liquid level detection instrument 2 and the second liquid level detection instrument 3 are connected to the control box 5 (control unit) through the instrument cable 6, and the control box 5 provides power for the first liquid level detection instrument 2 and the second liquid level detection instrument 3 . After the control box 5 is powered on, the first liquid level detection instrument 2 measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com