Photocatalyst solution for removing glue and method for removing glue at surface of liquid light-sensitive resin letterpress

A technology of photosensitive resin and photocatalyst, which is applied in the field of removing the surface stickiness of liquid photosensitive resin letterpress, and the field of photocatalyst solution for liquid photosensitive resin letterpress surface detackification, which can solve the problems of poor ability to transfer PI liquid, easy adhesion of dust, and uniform printing In order to improve the ability to transfer PI liquid, improve the uniformity of printing, and enhance the effect of photoreaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

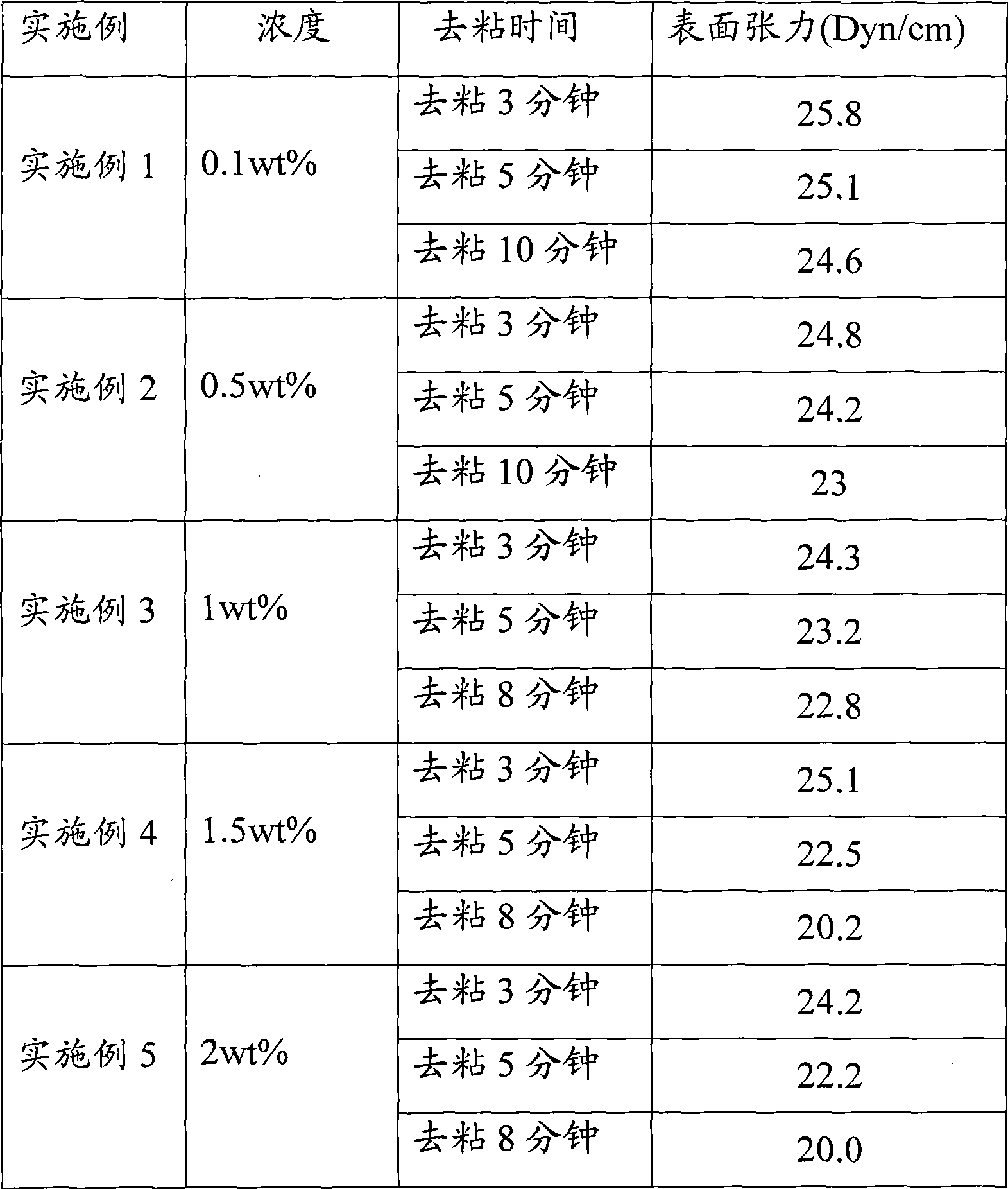

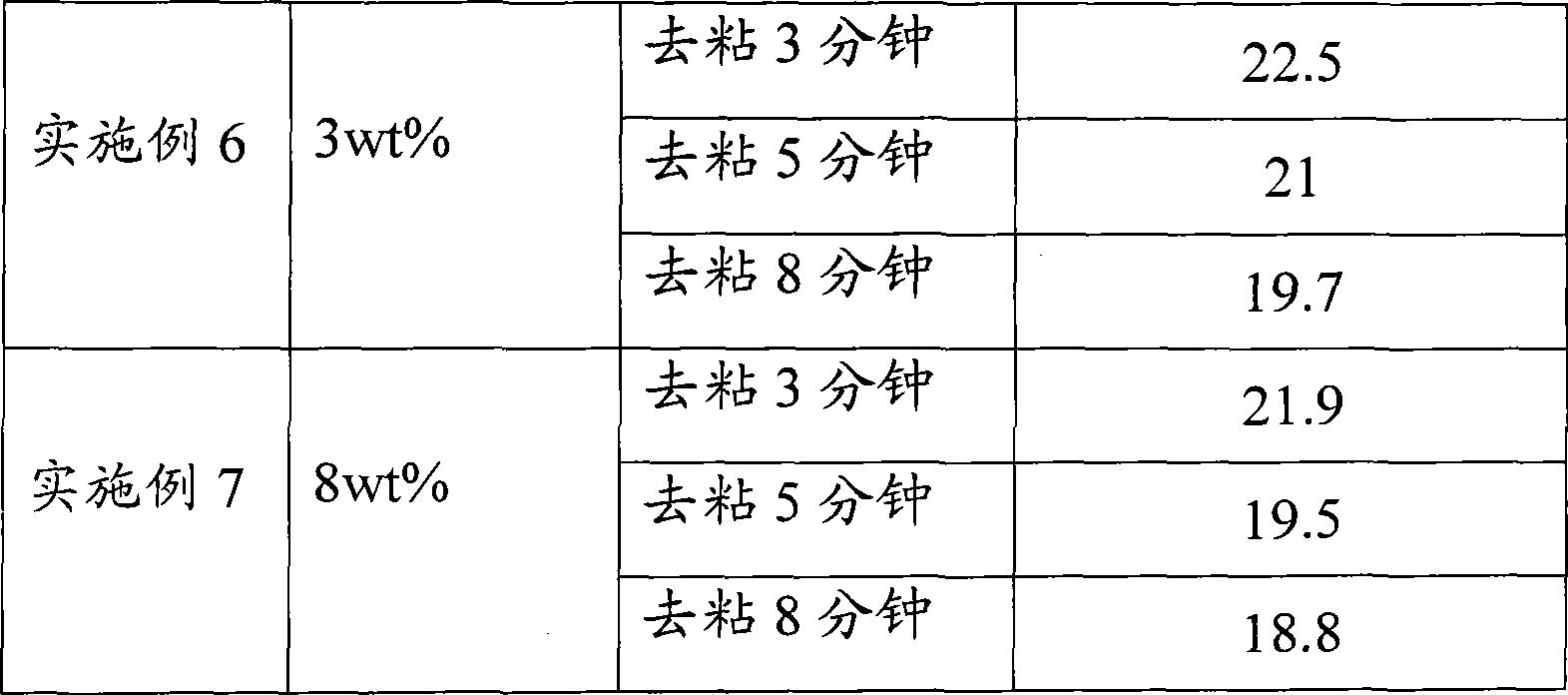

[0013] Take a certain amount of benzophenone and dissolve it in isopropanol, prepare a photocatalyst with a concentration of 0.1wt%, and coat it on the liquid photosensitive resin, using an ultraviolet light source with a wavelength of 254nm, at a light intensity of 60mw / cm 2 The surface of the letterpress was irradiated under certain conditions, and the surface tension was tested under different detackification times. See Table 1 for specific data.

Embodiment 2

[0015] Dissolve a certain amount of benzophenone in isopropanol, prepare a photocatalyst with a concentration of 0.5wt%, and coat it on the surface of the liquid photosensitive resin relief, using an ultraviolet light source with a wavelength of 254nm, at a light intensity of 60mw / cm 2 The surface of the letterpress was irradiated under certain conditions, and the surface tension was tested under different detackification times. See Table 1 for specific data.

Embodiment 3

[0017] Take a certain amount of benzophenone and dissolve it in isopropanol, prepare a photocatalyst with a concentration of 1wt%, and coat it on the surface of the liquid photosensitive resin relief, using an ultraviolet light source with a wavelength of 254nm, at a light intensity of 60mw / cm 2 The surface of the letterpress was irradiated under certain conditions, and the surface tension was tested under different detackification times. See Table 1 for specific data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com