Self-propelled travelling-crane feeding system for H shaped cage system

A feeding system and cage technology, applied in the field of automated animal husbandry equipment, can solve problems affecting normal use, loss, and damaged power of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

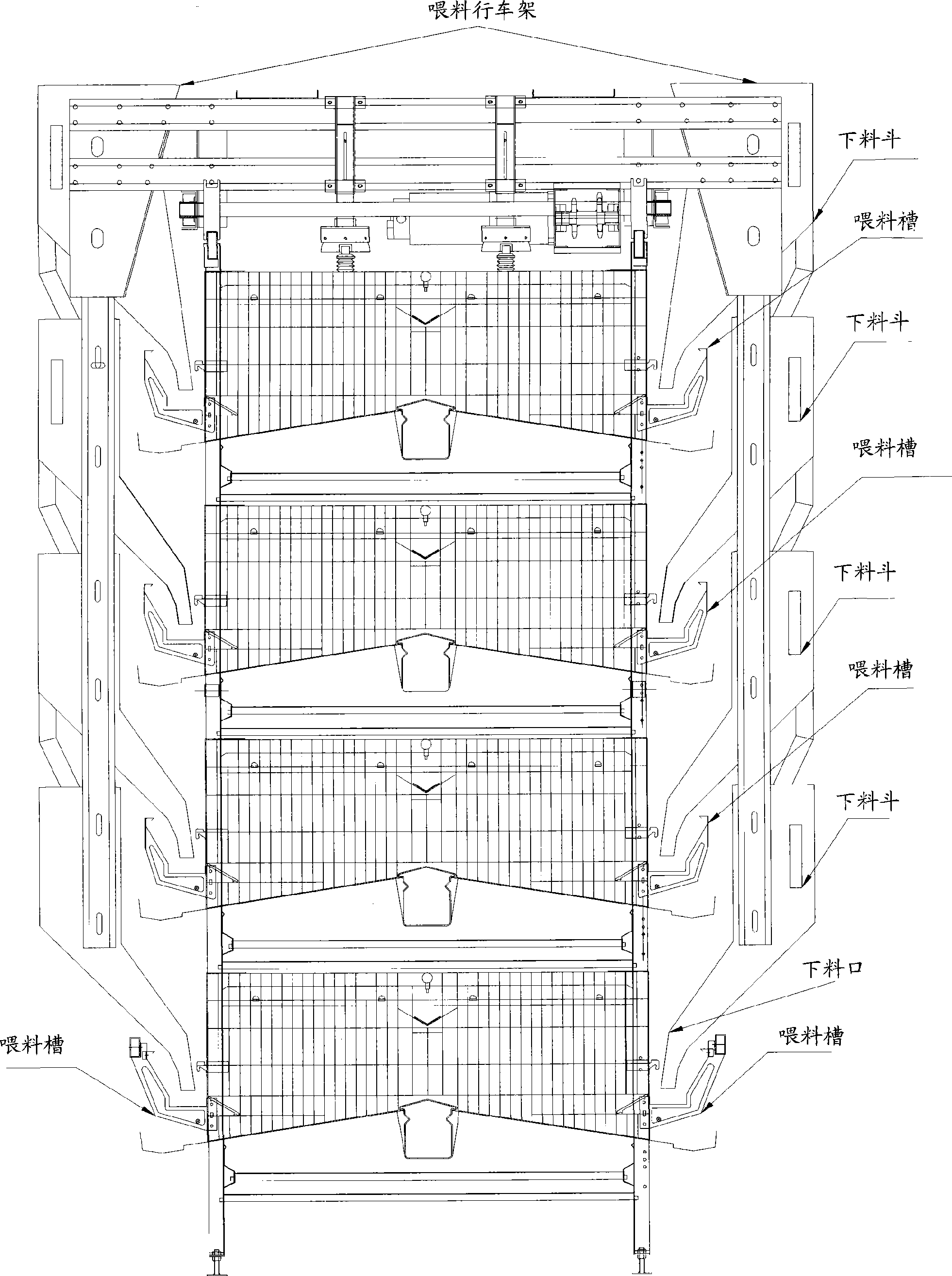

[0038] The H-type cage system is composed of multiple layers of parallel cages. Parallel feeding troughs (not shown in the figure) are arranged on both sides of the cage system. Each feeding trough is used to feed the birds in each layer of cages. feed.

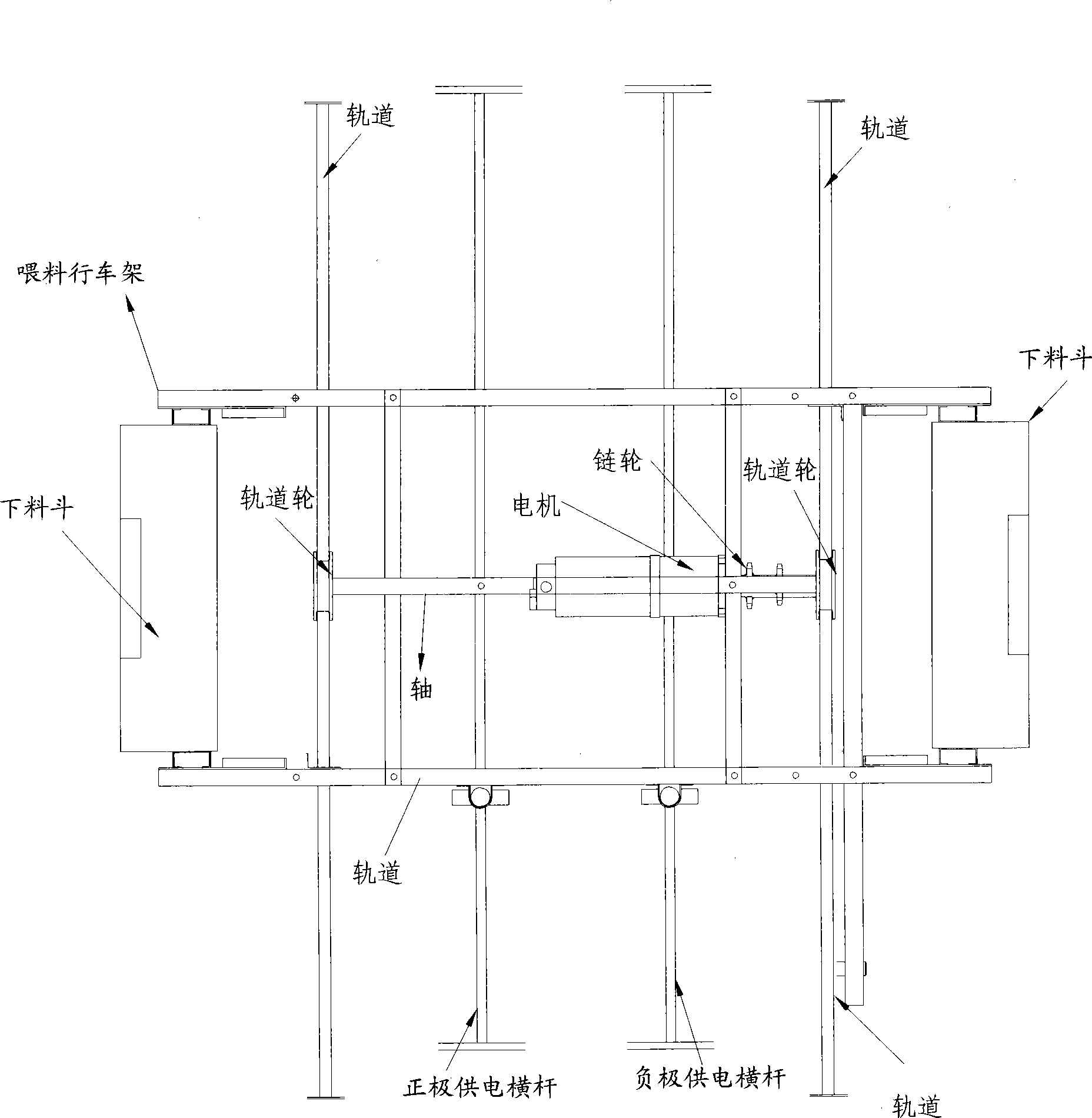

[0039] see figure 1 , The crane feeding system that is used for the H type cage system of the present embodiment comprises: the feeding truck frame, and the track parallel to the feeding trough (not shown in the figure). Wherein, the feeding carriage is provided with at least one lower hopper, and each lower hopper is connected, like this, feed can be added at the uppermost lower hopper, and the feed is shunted to each lower hopper due to the effect of gravity.

[0040] The feeding openings of each lower hopper are respectively located above each feeding trough, so that the feed added to the uppermost lower hopper of the feeding carriage flows to the lower hoppers of each layer, and is added to each feeding trough through th...

Embodiment 2

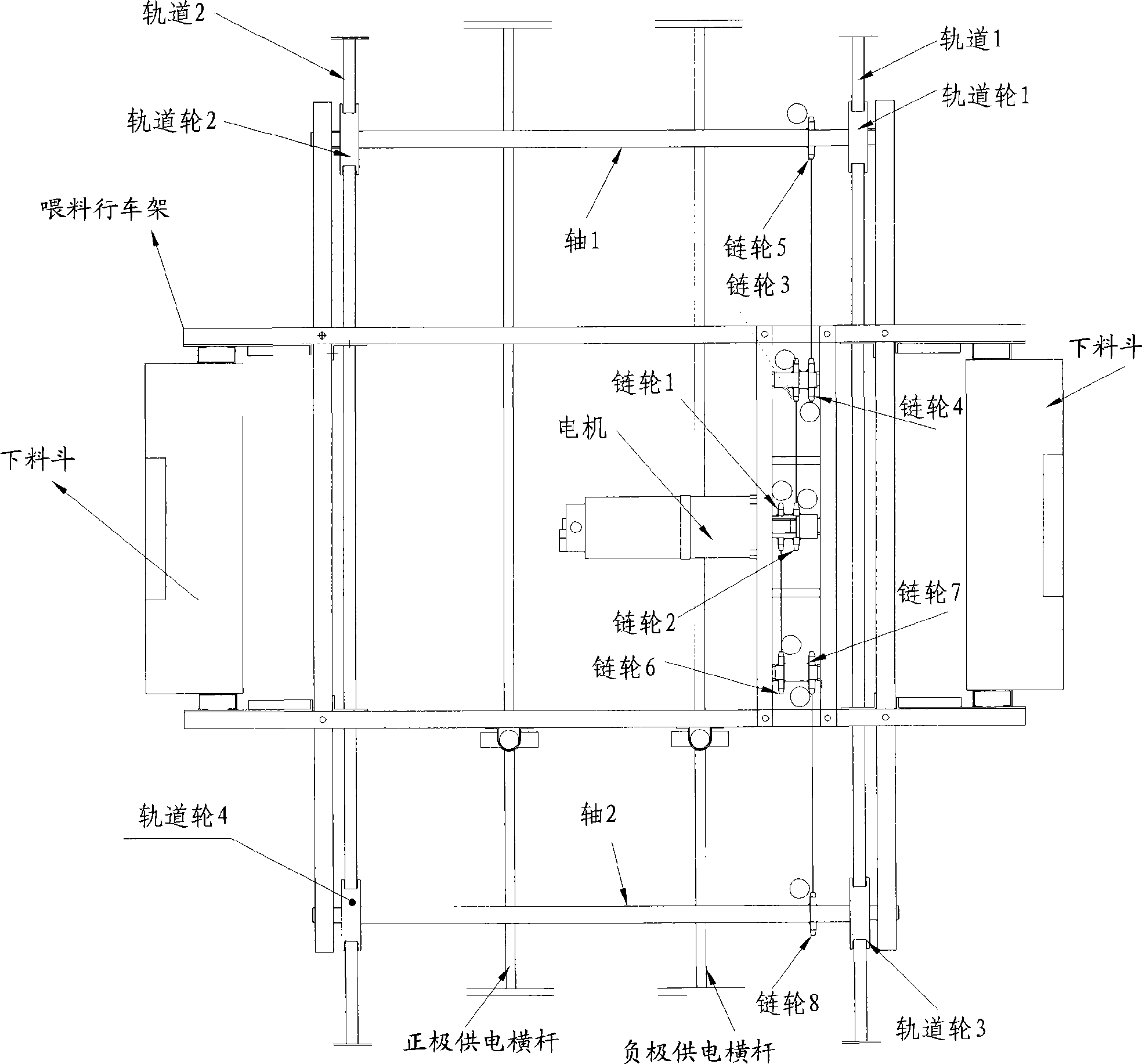

[0056] This embodiment provides another self-propelled driving feeding system, see figure 2 , 3 , this system differs from Embodiment 1 in that:

[0057] The motor is connected coaxially with the first sprocket set (sprocket 1 and sprocket 2 connected coaxially). The motor drives the first sprocket set (sprocket 1, sprocket 2) to rotate.

[0058] A second sprocket set (coaxially connected sprocket 3, sprocket 4) and a third sprocket set (coaxially connected sprocket 6, sprocket 7) are respectively arranged on both sides of the first sprocket set. And sprocket 1, sprocket 3 are connected by hinge, and sprocket 2, sprocket 4 are connected by hinge.

[0059] On the outside of the second sprocket set and the third sprocket set, shafts 1 and 2 are also arranged, and sprocket 5 , track wheel 1 and track wheel 2 are fixedly arranged on shaft 1 . Track wheel 1, track wheel 2 are arranged on track 1, track 2 respectively, and sprocket wheel 5 is connected with sprocket wheel 4 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com