Insulation potlike container

An insulation tank type and container technology, applied in packaging, transportation, packaging, containers, etc., can solve the problems of the thickness limitation of the insulation layer 11, the increase of the tank body weight, and the impact on transportation, etc., to achieve good economic benefits, reduce self weight, and reduce heat dissipation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

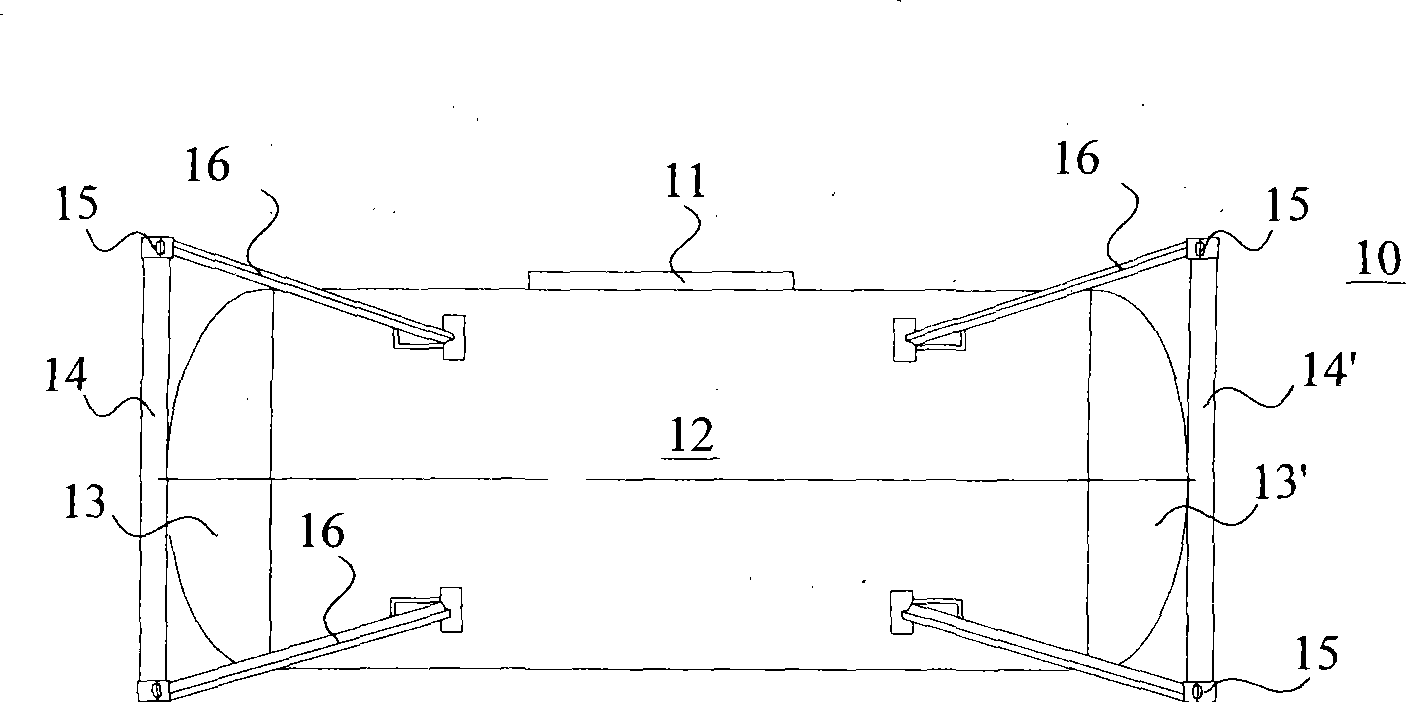

[0016] The insulation tank container of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the technical solutions of the present invention can also be applied to other logistics transportation containers or similar devices.

[0017] The insulation tank type container of the present invention and figure 1 The tank container 10 of the prior art shown has the same structure, and the difference is that the outer layer of the connecting piece 16 between the frame and the tank body of the present invention is covered with an insulating layer to reduce the stress on the connecting piece 16. heat loss. Preferably, the insulation layer covering the outer layer of the connecting piece 16 is an insulating coating sprayed on the outer surface of the connecting piece 16 . The thermal insulation coating sprayed on the connector 16 has the advantages of water resistance, strong adhesion and thin thickness.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com