Full dacron soft pile blanket and its processing method

A processing method and technology for blankets, applied in heating/cooling fabrics, elongation of fabrics, thorn patterns, etc., can solve the problems of changing the feel and softness of blankets, loss of economy, environmental impact, etc., and achieve ideal surface flatness , Reasonable effect of raw material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

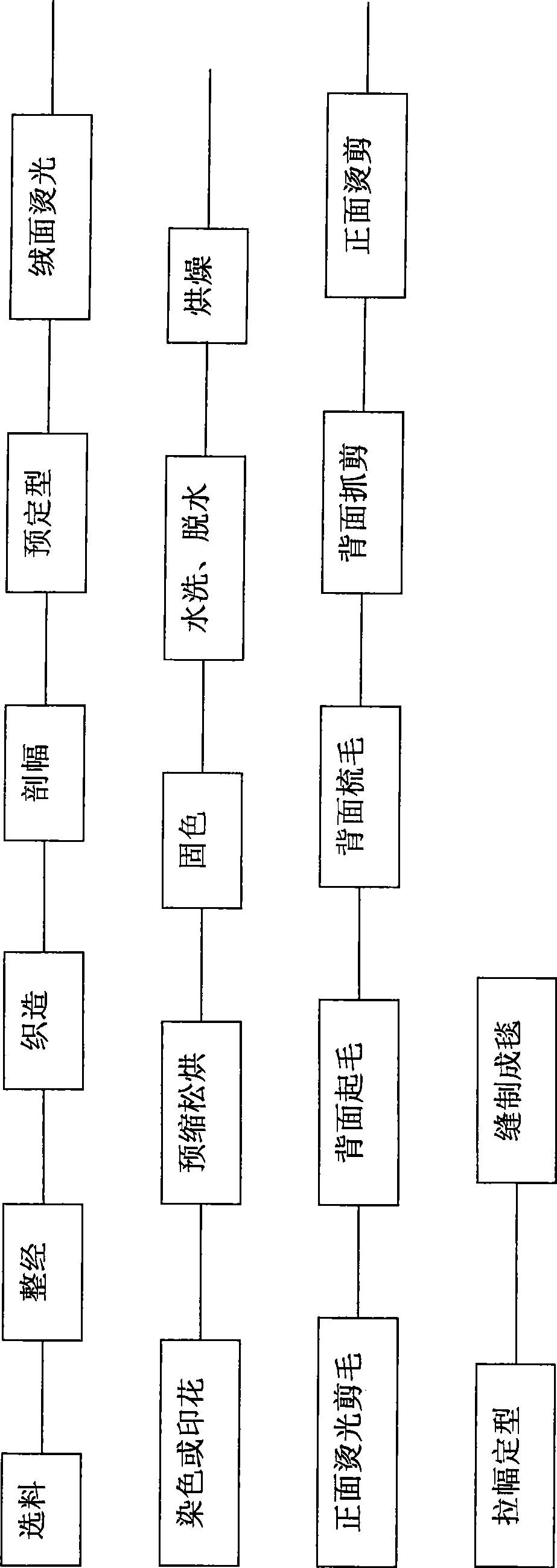

[0042] According to the technological process shown in the attached figure, the finished product specifications are 3.0mm in gross height and 180g / m in weight. 2 1. For example, single-layer polyester Shuft fleece with raised back, the mass percentage of DTY silk in the blanket is 50%, and the mass percentage of FDY silk in the blanket is 50%.

[0043]A) Material selection, choose DTY silk as the raw material of velvet yarn, and select FDY silk as the raw material of bottom silk, wherein, DTY silk refers to the DTY silk obtained by modifying POY silk, and the modification of POY silk to DTY silk is mentioned here. It is 150D / 288F DTY network yarn with POY yarn stretched to a fineness of 0.58dtex. During the texturing process, the temperature of the upper box is controlled at 160°C, and the temperature of the lower box is 143°C. The 55dtex FDY polyester filament sold as the base yarn;

[0044] B) warping, warping the selected DTY silk and FDY silk with a warping machine;

[0...

Embodiment 2

[0062] According to the technological process shown in the attached figure, the finished product specifications are 7.0mm in gross height and 400g / m in weight. 2 1. For example, single-layer polyester Shuft fleece with raised back surface, the mass percentage of DTY silk in the blanket is 60%, and the mass percentage of FDY silk in the blanket is 40%.

[0063] A) Material selection, choose DTY silk as the raw material of velvet yarn, and select FDY silk as the raw material of bottom silk, wherein, DTY silk refers to the DTY silk obtained by modifying POY silk, and the modification of POY silk to DTY silk is mentioned here. It is 150D / 288F DTY network yarn with POY yarn stretched to 0.77dtex. During the texturing process, the temperature of the upper box is controlled at 162°C, and the temperature of the lower box is 146°C. The 111dtex FDY polyester filament sold as the base yarn;

[0064] B) warping, warping the selected DTY silk and FDY silk with a warping machine;

[0065]...

Embodiment 3

[0082] According to the technological process shown in the attached figure, the finished product specifications are 10.0mm in gross height and 800g / m in weight. 2 1. For example, single-layer polyester Shuft fleece with raised back, DTY silk accounts for 80% by mass in the blanket, and FDY silk accounts for 20% by mass in the blanket.

[0083] A) Material selection, choose DTY silk as the raw material of velvet yarn, and select FDY silk as the raw material of bottom silk, wherein, DTY silk refers to the DTY silk obtained by modifying POY silk, and the modification of POY silk to DTY silk is mentioned here. It is 150D / 288F DTY network yarn with POY yarn stretched to a fineness of 0.77dtex. During the texturing process, the temperature of the upper box is controlled at 170°C, and the temperature of the lower box is controlled at 153°C. The FDY polyester filament of commercially available 167dtex is used as the base yarn;

[0084] B) warping, warping the selected DTY silk and FD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com